Plugging-resistant freeze-resistant pervious concrete pavement brick and manufacturing method

A technology of permeable concrete and its production method, which is applied in the field of civil engineering, can solve the problems of reduced strength of pavement bricks, reduced permeability of permeable concrete, and clogged pores, and achieve the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

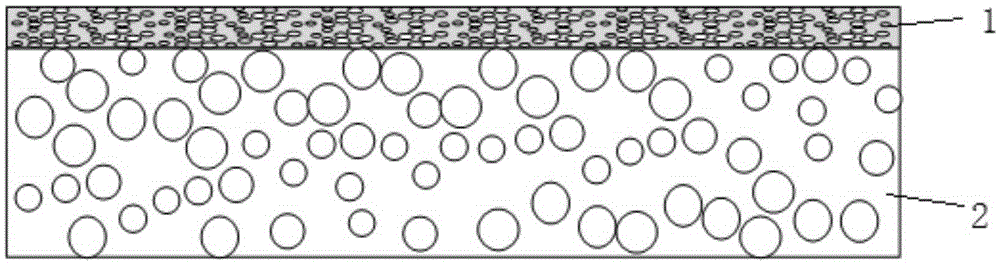

[0044] Embodiment 1: An anti-clogging and frost-resistant permeable concrete pavement brick, including an anti-clogging surface layer 1 and a base layer 2, and the anti-clogging surface layer 1 is located above the base layer 2;

[0045] The material components and proportions of the surface layer are: cement 80kg, coarse sand 310kg, silica fume 7kg, VAE emulsion 6kg, water 25kg, water reducer 0.8kg;

[0046] The material components and ratio of the base layer are: 90kg of cement, 220kg of gravel, 70kg of coarse sand, 8kg of silica fume, 8kg of VAE emulsion, 0.1kg of polyethylene fiber, 25kg of water and 0.8kg of water reducer.

[0047] The making method of above-mentioned pavement brick is:

[0048] A. Make base material in advance: mix water, water reducing agent and VAE emulsion to form a mixed aqueous solution, and set aside; put stones, coarse sand and polyethylene fiber into the mixer and stir for 20 seconds, add 1 / 3 of the mixed aqueous solution, and stir for 10 seconds...

Embodiment 2

[0056] Embodiment 2: An anti-clogging and frost-resistant permeable concrete pavement brick, including an anti-clogging surface layer 1 and a base layer 2, and the anti-clogging surface layer 1 is located above the base layer 2;

[0057] The material components and proportions of the surface layer are: 100kg of cement, 360kg of coarse sand, 11kg of silica fume, 10kg of VAE emulsion, 35kg of water, and 1.2kg of water reducing agent;

[0058] The material components and ratio of the base layer are: 110kg of cement, 260kg of gravel, 110kg of coarse sand, 12kg of silica fume, 12kg of VAE emulsion, 0.4kg of polyethylene fiber, 35kg of water and 1.2kg of water reducer.

[0059] The making method of above-mentioned pavement brick is:

[0060] A. Make base material in advance: mix water, water reducing agent and VAE emulsion to form a mixed aqueous solution, and set aside; put stones, coarse sand and polyethylene fiber into the mixer and stir for 40 seconds, add 1 / 3 of the mixed aqueo...

Embodiment 3

[0067] Embodiment 3: An anti-clogging and frost-resistant permeable concrete pavement brick, including an anti-clogging surface layer 1 and a base layer 2, and the anti-clogging surface layer 1 is located above the base layer 2;

[0068] The material components and proportions of the surface layer are: cement 85kg, coarse sand 320kg, silica fume 8kg, VAE emulsion 7kg, water 27kg and water reducing agent 0.9kg;

[0069] The material components and ratio of the base layer are: 95kg of cement, 230kg of gravel, 80kg of coarse sand, 9kg of silica fume, 9kg of VAE emulsion, 0.2kg of polyethylene fiber, 27kg of water and 0.9kg of water reducer.

[0070] The making method of above-mentioned pavement brick is:

[0071] A. Make base material in advance: mix water, water reducing agent and VAE emulsion to form a mixed aqueous solution, and set aside; put stones, coarse sand and polyethylene fiber into the mixer and stir for 20 seconds, add 1 / 3 of the mixed aqueous solution, and stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com