Special compound wax for emulsion explosives based on heavy deasphalting oil

A technology for heavy deasphalting oil and emulsion explosives, applied in the field of compound wax, can solve the problems of competition for raw materials, harsh raw material requirements, etc., and achieve the effect of avoiding the increase of production cost and excellent performance.

Active Publication Date: 2016-03-09

CHINA PETROLEUM & CHEM CORP

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to solve the problem that the existing emulsion explosive composite wax products have strict requirements on raw materials, compete with petroleum wax and microcrystalline wax for raw materials, and meet the production process of new emulsion explosives and higher blasting performance requirements

This product not only has good blasting performance, but also solves the problem that the existing emulsion explosive composite wax has strict requirements on raw materials and competes with petroleum wax and microcrystalline wax for raw materials from the source of raw materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

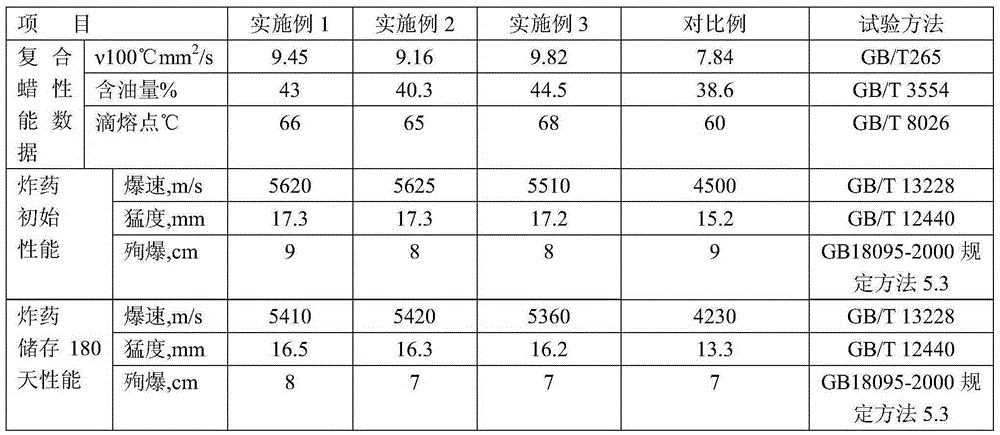

[0019] The composition (percentage by weight) of the special composite wax product for emulsion explosives based on heavy deasphalted oil of the present invention is shown in Table 2.

[0020] Each group distribution ratio of table 2 embodiment 1-3

[0021] raw material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses special compound wax for emulsion explosives based on heavy deasphalting oil. The special compound wax comprises the following components: heavy deasphalting oil, dewaxing sweat oil, Fischer-tropsch wax and cerate. The preparation method comprises the following steps: melting the heavy deasphalting oil, sequentially adding the residual components under the condition of 85 to 95 DEG C, uniformly mixing, cooling and forming the product. The heavy deasphalting oil and dewaxing sweat oil serve as main raw materials, and the condition that the raw materials are contested during production of microcrystalline wax and petroleum wax; wax-containing raw resources in oil refinery are directly and effectively utilized, and the condition that the production cost is improved due to secondary processing is avoided; the use amount of cerate is as small as possible, so that the cost of the compound wax is reduced to the lowest degree; and the Fischer-tropsch wax at relatively low price is introduced, so that the viscosity, hardness, oil content and the like of the product are adjusted, and the requirements on novel emulsion explosive production process and performance improvement are met.

Description

technical field [0001] The invention relates to a compound wax specially used for emulsion explosives, and belongs to the technical field of petrochemical products. Background technique [0002] Explosives have a wide range of uses in the national economy and are generally valued by people. Emulsion explosives are a kind of water-in-oil emulsion type water-resistant industrial explosives developed by emulsification technology in the late 1960s. It not only solves the sensitivity problem of nitroglycerin explosives, that is to say, under the premise of ensuring the performance of explosives, it effectively improves the safety, but also solves the problem of low detonation sensitivity of ammonium nitrate explosives. Therefore, emulsion explosives are explosives Industry trends. The oil phase material constitutes the continuous phase of the emulsion explosive. In the emulsion explosive system, due to the limitation of oxygen balance and blasting performance requirements, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C06B23/00

CPCC06B23/00C06B23/006

Inventor 王海燕

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com