Deactivated SCR denitration catalyst purging device, activation device and regeneration system and corresponding methods

A denitration catalyst and catalyst technology, which are applied in catalyst activation/preparation, catalyst regeneration/reactivation, chemical instruments and methods, etc., can solve the problems of increasing denitration costs, environmental pollution, and catalyst costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

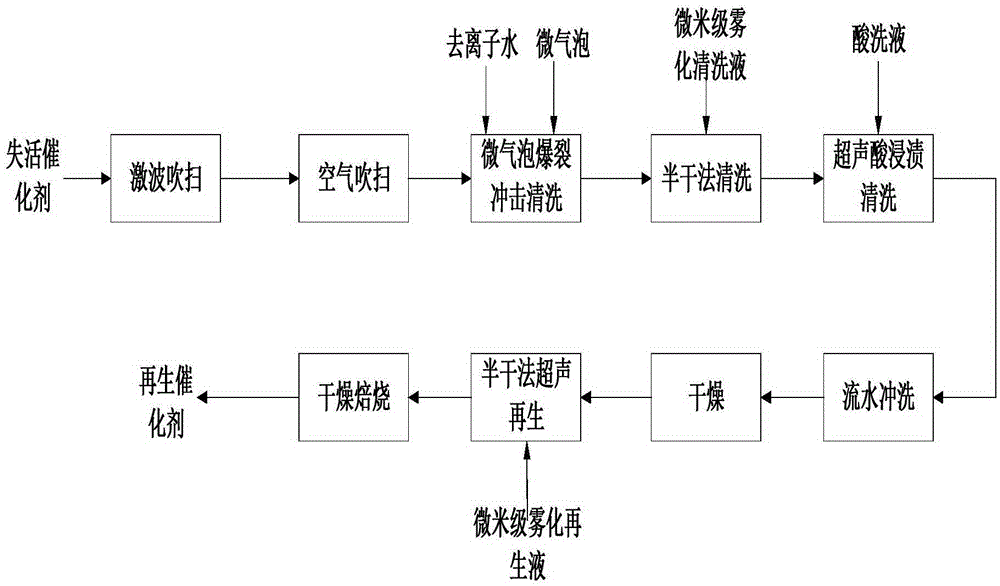

[0123] go through Figure 1-5 The method and system shown can achieve a denitrification activity of 18Nm / h and a specific surface area of 41.2m 2 The regeneration treatment of the catalyst (referred to as deactivated catalyst A) of / g:

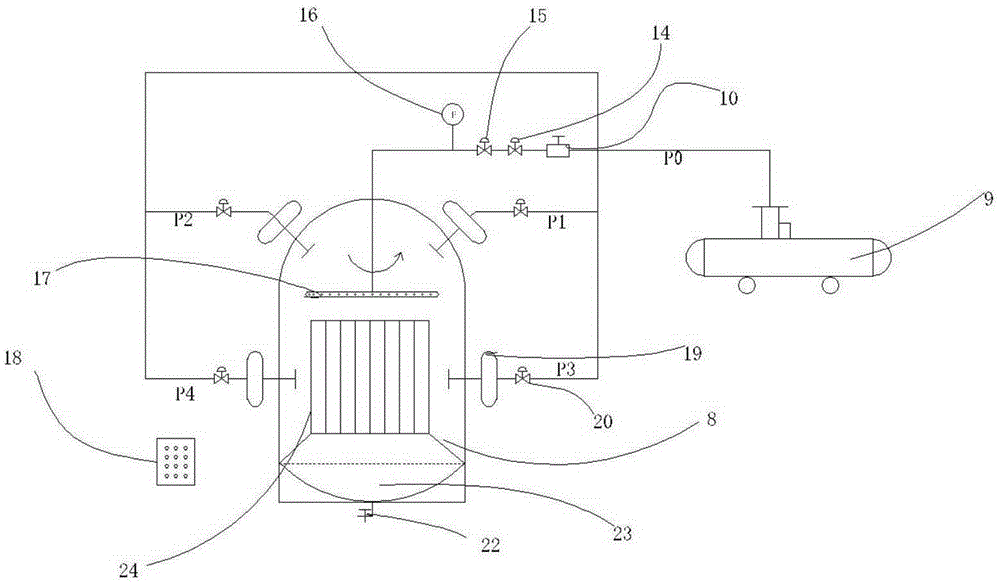

[0124] (1) Place deactivated catalyst A in figure 2 In the purging device shown, a shock wave soot blower is used for purging, and the number of shock wave soot blowing is 7 times (among them, 4 times of soot blowing on both sides of the middle part, and 3 times of soot blowing on both sides of the upper part), with less soot blowing dead angle , It can blow out the stubborn dust, and then blow it with clean air with a pressure of 0.55MPa for 20 minutes;

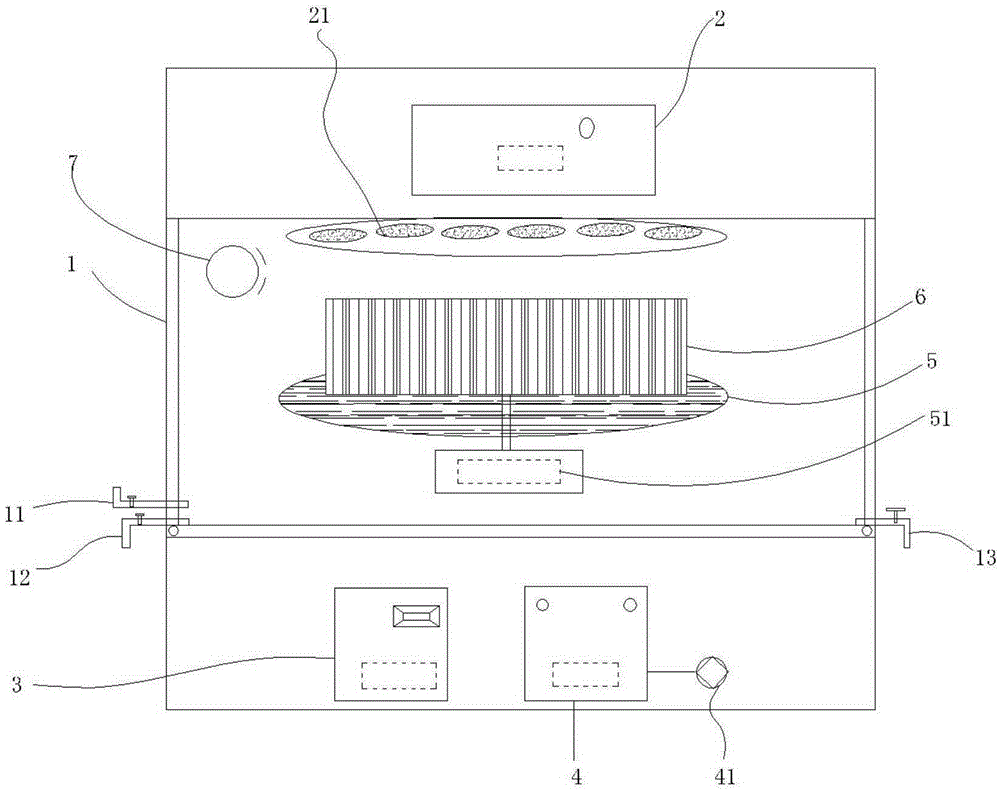

[0125] (2) Place the catalyst after (1) treatment in image 3 In the airtight cleaning device shown, the microbubble burst impact cleaning method was used to clean for 22 minutes (wherein, the ultrasonic frequency is 35KHz, and the flow rate of the air pump is 0.6m 3 / h), and then use...

Embodiment 1-2

[0133] go through Figure 1-5 The method and system shown can achieve a denitrification activity of 18Nm / h and a specific surface area of 41.2m 2 The regeneration treatment of the catalyst (referred to as deactivated catalyst A) of / g:

[0134] (1) Place deactivated catalyst A in figure 1 In the purging device shown, the shock wave soot blower is used for blowing, and the number of shock wave soot blowing is 7 times (among which, the soot blowing on both sides of the middle part is 4 times, and the soot blowing on both sides of the upper part is 3 times), and then the pressure Blow with 0.55MPa clean air for 20 minutes;

[0135] (2) Place the treated catalyst in (1) in a cleaning device for ultrasonic cleaning for 20-50 min;

[0136] (3) drying the catalyst cleaned in (2) at 90° C. for 3 hours in the first drying device;

[0137] (4) Place the dried catalyst of (3) in a known active device, and regenerate it for 3 hours with the regeneration active solution;

[0138] (5...

Embodiment 2

[0143] go through Figure 1-5 The method and system shown can achieve a denitrification activity of 25Nm / h and a specific surface area of 37.8m 2 The regeneration treatment of the catalyst (referred to as deactivated catalyst B) of / g:

[0144] (1) Place deactivated catalyst B in figure 2 In the purging device shown, a shock wave soot blower is used for purging, and the number of shock wave soot blowing is 8 times (among them, 4 times of soot blowing on both sides of the middle part, and 4 times of soot blowing on both sides of the upper part), with less soot blowing dead angle , It can blow out the stubborn dust, and then blow it with clean air with a pressure of 0.45MPa for 15 minutes;

[0145] (2) Place the catalyst after (1) treatment in image 3 In the airtight cleaning device shown, the microbubble burst impact cleaning method was used to clean for 20 minutes (wherein, the ultrasonic frequency was 35KHz, and the flow rate of the air pump was 0.5m 3 / h), and then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com