A kind of soy sauce brewing mash making process and soy sauce crude oil brewing process

A soy sauce and process technology, which is applied in the field of soy sauce brewing and mash production, can solve the problems of affecting the utilization rate of raw materials, such as amino acid conversion rate, low production efficiency, and protease inactivation, so as to improve the utilization rate of raw materials, increase color and luster, and accelerate the post-ripening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

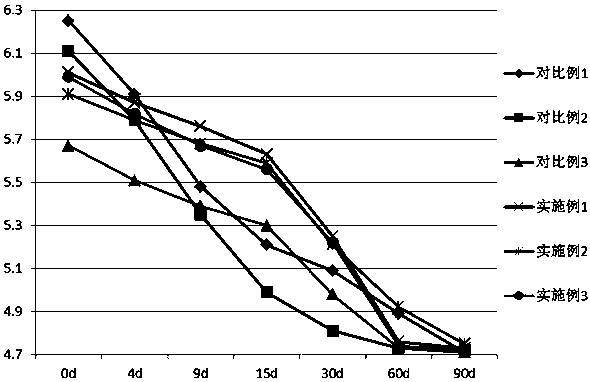

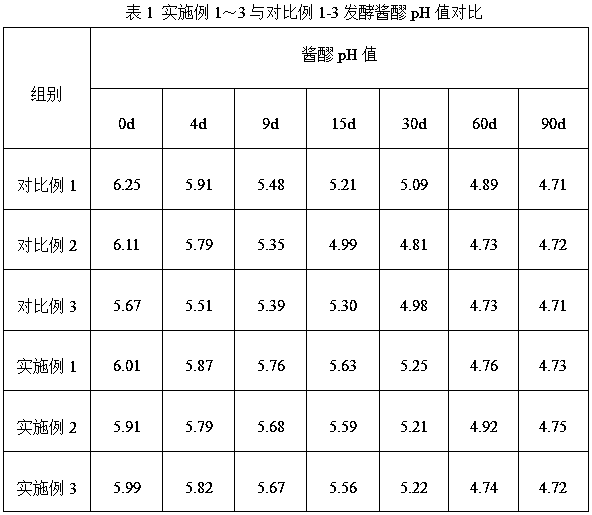

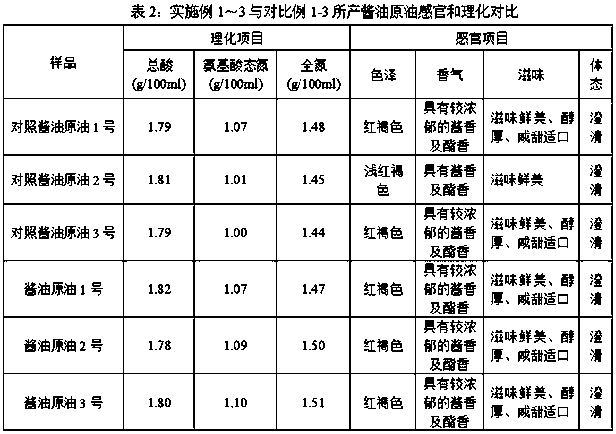

[0035] (1) 1 mass part of soybeans is steamed at 0.15Mpa steam pressure for 6 minutes, mixed with 0.5 mass parts of flour, cooled and inoculated with 0.05% (w / w) of soybean weight (w / w) Aspergillus oryzae, at 28-38°C and 85% humidity , cultivated for 45 hours to obtain Daqu with soy sauce.

[0036] (2) Mix soy sauce daqu with brine containing three oils at a concentration of 23±0.5g / 100ml at a mass ratio of 1:2.3 to form a moromi. The volume fraction of three oils in brine is 30%, using GB18186-2000 The recorded high-salt dilute soy sauce brewing method is used for fermentation, and the oil is released after 120 days of fermentation to obtain crude oil, which is filtered to obtain No. 1 soy sauce crude oil.

Embodiment 2

[0038] (1) 1 mass part of soybeans is steamed at 0.15Mpa steam pressure for 6 minutes, mixed with 0.5 mass parts of flour, cooled and inoculated with 0.05% (w / w) of soybean weight (w / w) Aspergillus oryzae, at 28-38°C and 85% humidity , cultivated for 45 hours to obtain Daqu with soy sauce.

[0039] (2) Mix soy sauce daqu with brine containing three oils at a concentration of 23±0.5g / 100ml at a mass ratio of 1:2.3 to form moromi. The volume fraction of three oils in brine is 50%, using GB18186-2000 Ferment the high-salt dilute soy sauce brewing method recorded in , and drain the oil after 120 days of fermentation to obtain crude oil, which is filtered to obtain No. 2 soy sauce crude oil.

Embodiment 3

[0041] (1) 1 mass part of soybeans is steamed at 0.15Mpa steam pressure for 6 minutes, mixed with 0.5 mass parts of flour, cooled and inoculated with 0.05% (w / w) of soybean weight (w / w) Aspergillus oryzae, at 28-38°C and 85% humidity , cultivated for 45 hours to obtain Daqu with soy sauce.

[0042] (2) Mix soy sauce daqu with brine containing three oils at a concentration of 23±0.5g / 100ml at a mass ratio of 1:2.3 to form a moromi. The volume fraction of three oils in brine is 40%, using GB18186-2000 The recorded high-salt dilute soy sauce brewing method is used for fermentation, and the oil is drained after 120 days of fermentation to obtain crude oil, which is filtered to obtain No. 3 soy sauce crude oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com