Method for producing prestressed concrete structures by means of profiles made of shape memory alloys and structures built according to this method

A technology of concrete structure and memory alloy, applied in the direction of structural elements, buildings, building components, etc., can solve the problem that anti-corrosion is no longer guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

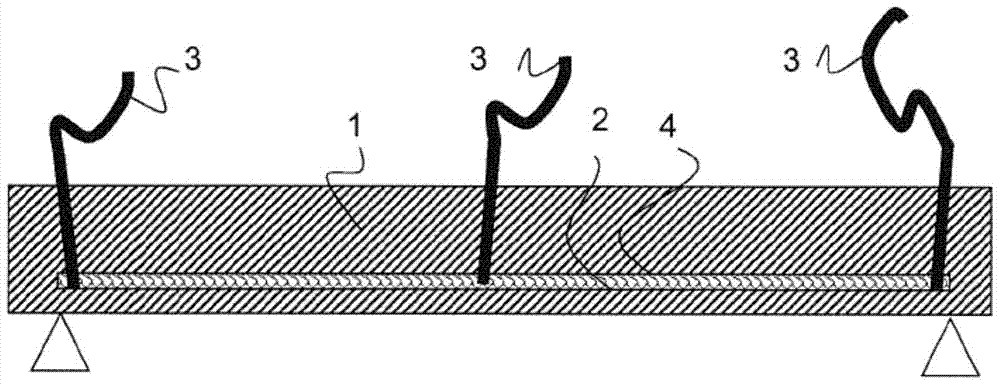

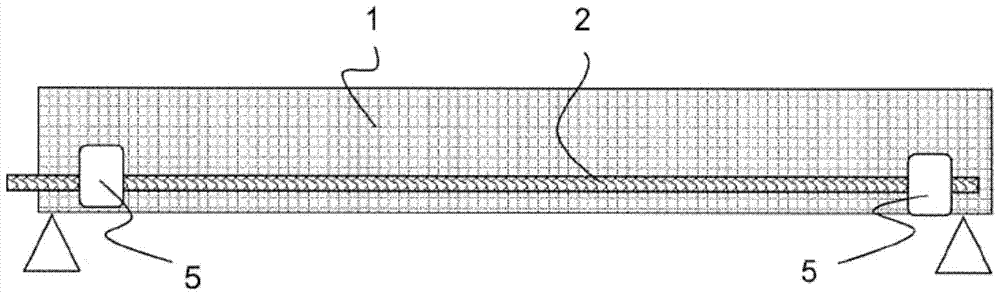

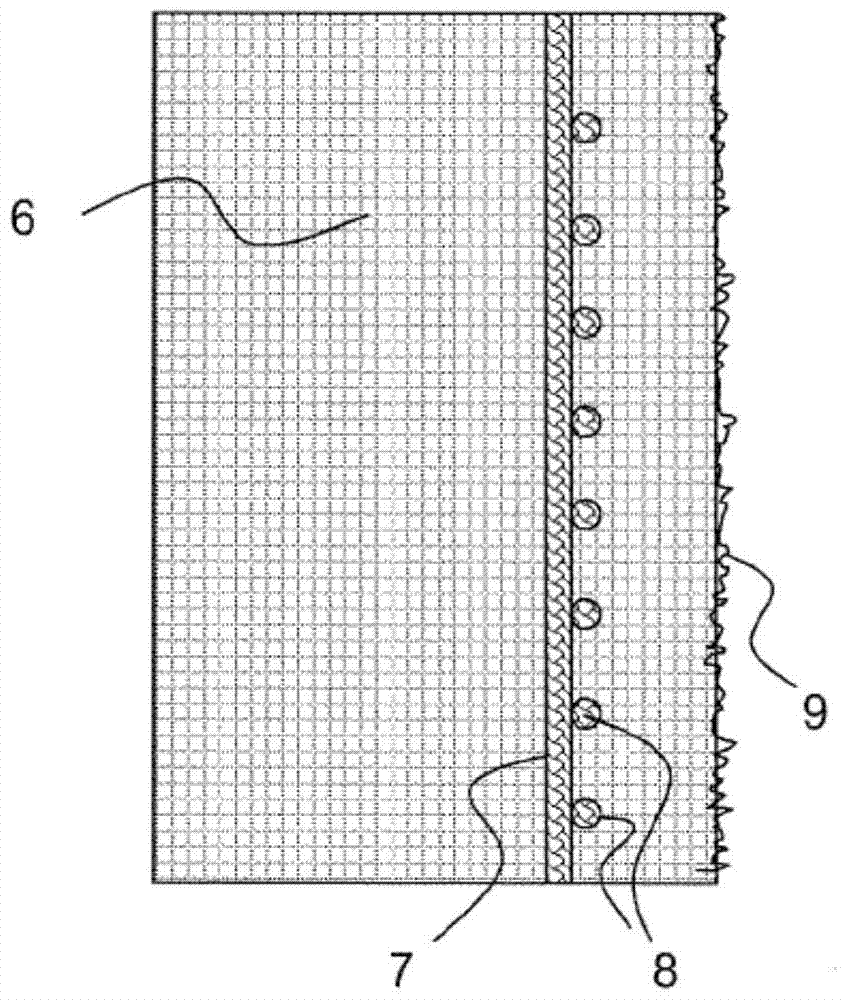

[0021] First, we must understand the properties of shape memory alloys. Some alloys show specific structures that depend on changes in heat but return to their original state after the heat is released. Just like other metals or alloys, these shape memory alloys (SMA) contain more than one crystal structure. They are polymorphic and therefore polycrystalline metals. The main crystal structure of shape memory alloy (SMA) depends on its temperature on the one hand, and on the other hand external stress, that is, tension or compression. When the temperature is higher, the alloy is called austenite, when the temperature is lower, the alloy is called martensite. The special feature of these shape memory alloys (SMA) is that even when they have previously been deformed in the low temperature stage, they can assume their original structure and shape after the temperature is raised in the high temperature stage. This effect can be used to apply prestress to the building structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com