A transformer using an epoi-shaped multipurpose ferrite core

A ferrite core and transformer technology, applied in transformer/inductor cores, transformer/inductor parts, electrical components, etc., can solve the problem of poor heat and oxygen aging resistance, low mechanical strength, and long service life Short and other problems, achieve good magnetic shielding effect, maintain consistency, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

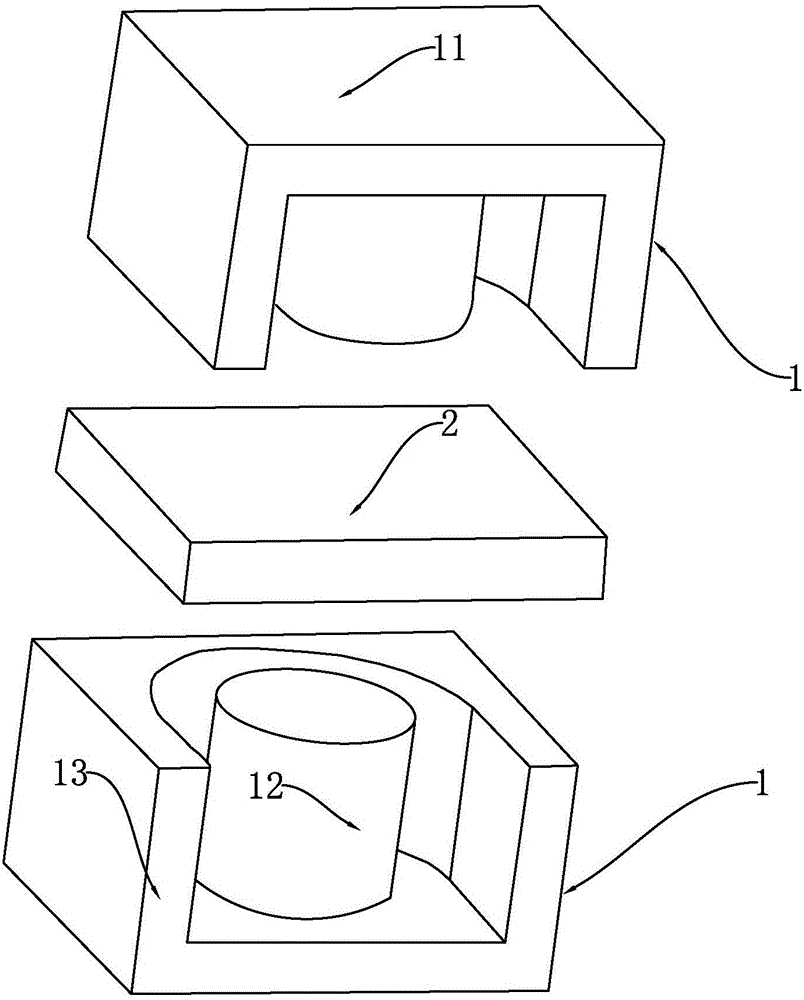

[0019] Such as figure 1 , shown, a kind of EPO I shape multi-purpose ferrite magnetic core, comprises two EPO shape magnetic cores and an I chip shape magnetic core and is combined, and described EPO shape magnetic core comprises bottom surface 11, center post 12 and side legs 13; the bottom surface 11 is a square, the cross-section of the central column 12 is oval, the side legs 13 are arc-shaped and surround the central column 12, and lead holes are left on both sides of the central column 12, and the central column 12 and I There is a gap between the sheets, and the distance between the two sides of the central column and the arc edge is the same.

[0020] In the present embodiment, while the total height of the EPOI shape multi-purpose ferrite core is 4mm, the bottom surface of the magnetic core is a square side length of 8mm, the central column of the magnetic core is elliptical, and the short of the elliptical The axis is 2.7mm and the major axis is 5.2mm.

[0021] Thi...

Embodiment 2

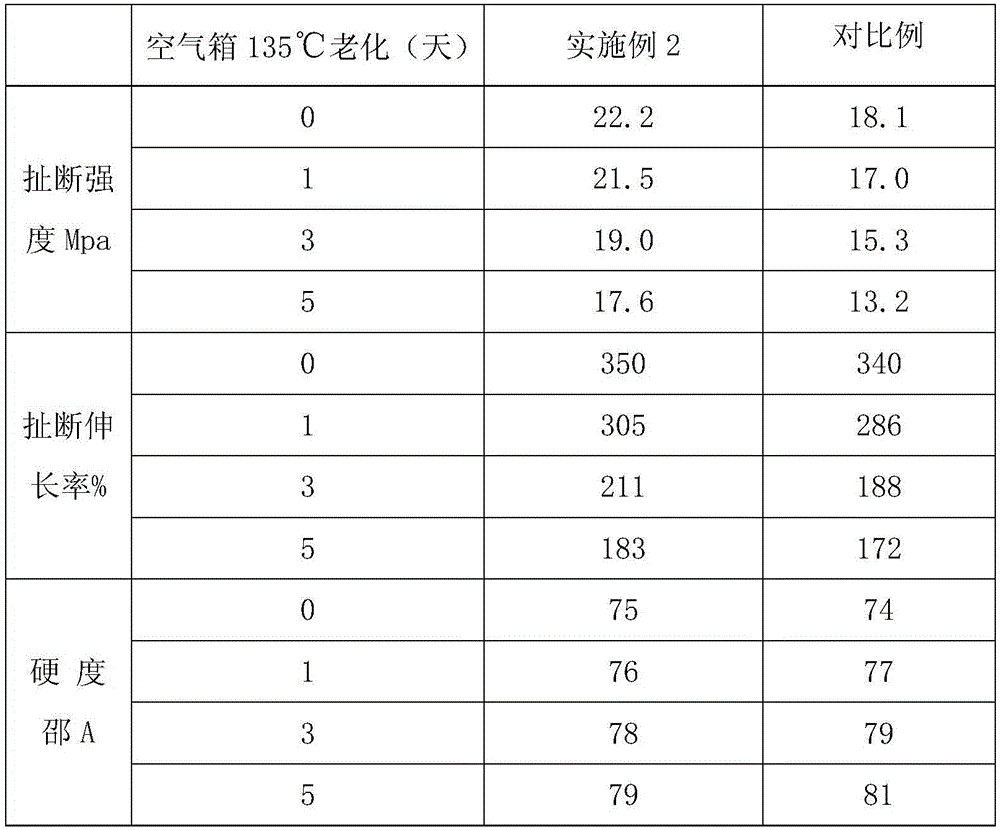

[0025] The above-mentioned EPDM rubber used in the transformer has the following weight ratio: 75 parts of EPDM, 10 parts of IIR, 15 parts of ultra-high molecular weight polyethylene, 1 part of anti-aging agent RD, 1 part of anti-aging agent BLE-W, 3 parts of zinc oxide 25 parts of white carbon black, 40 parts of magnesium hydroxide, 5 parts of zinc borate, 4 parts of paraffin oil, 1 part of Turkish red oil, 2 parts of microcrystalline wax, 3 parts of DCP, 1 part of vulcanizing agent Shuangwuwu, 1 part of soda ash parts, 0.5 parts of sulfur.

[0026] The vulcanization is carried out by the method of secondary vulcanization. The temperature of the first stage of vulcanization is 170°C~180°C, and the vulcanization time is 5'~10'; the temperature of the second stage vulcanization is 170°C, and the vulcanization time is 90'.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com