Gas tight test board of hydraulic valve

A technology for air tightness testing and hydraulic valves, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, machine/structural component testing, etc. It can solve the problems of low detection efficiency, air pressure and air leakage Insufficient inspection accuracy and other issues, to achieve high explosion-proof safety performance, compact structure, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

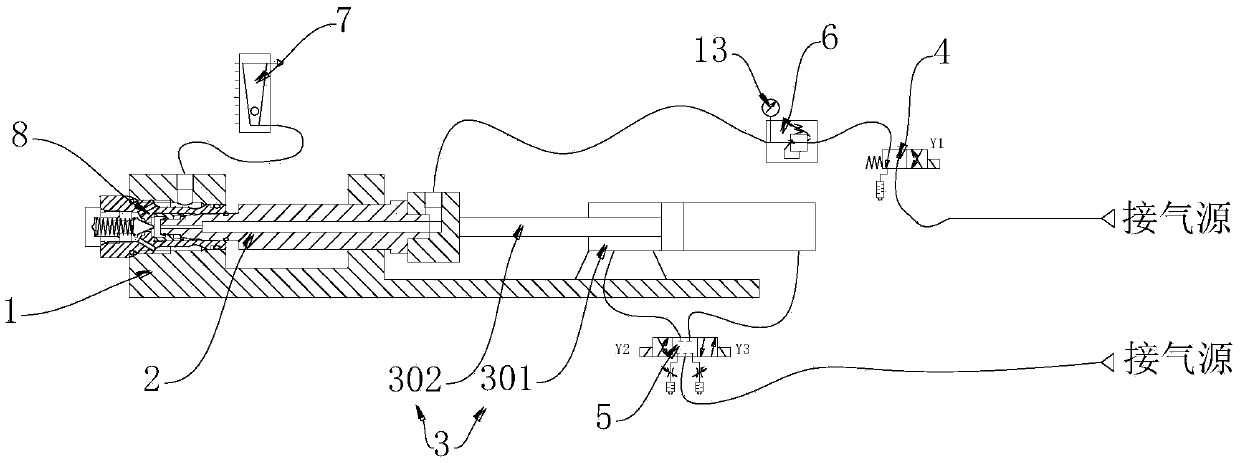

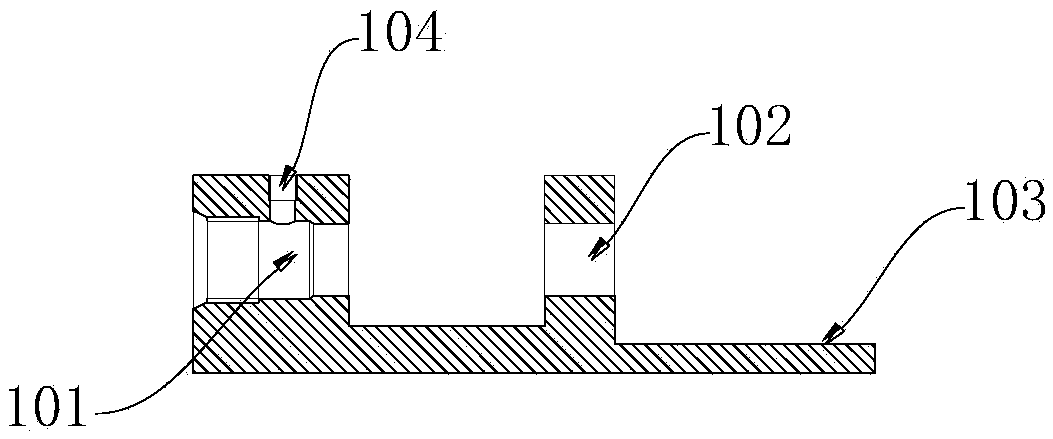

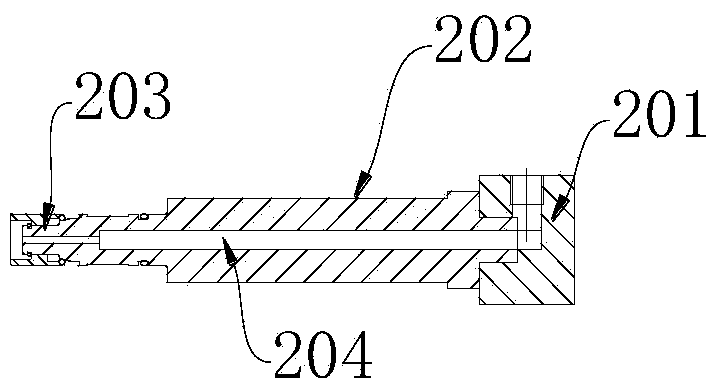

[0022] Embodiment 1 of the present invention: as Figures 1 to 3 As shown, a hydraulic valve airtight test bench includes a first station A, characterized in that the first station A includes a test unit A1 and an installation unit A2, and the test unit A1 includes a valve block component 1, Sealing tooling 2, pneumatic two-position four-way reversing valve 4, first pneumatic pressure reducing valve 6 and gas glass rotameter 7; said installation unit A2 includes cylinder 3 and pneumatic three-position five-way reversing valve 5; said The valve block part 1 includes a valve body installation part 101, a tooling installation part 102, a cylinder installation part 103 and a gas discharge port 104; the cylinder 3 includes a cylinder barrel 301 and a piston rod 302; the sealing tooling 2 includes a tooling exhaust part 203 , the tooling fixing part 202, the tooling air intake part 201 and the tooling internal through hole 204.

[0023] The cylinder barrel 301 of the cylinder 3 is ...

Embodiment 2

[0026] Embodiment 2 of the present invention: as Figure 4 As shown, a hydraulic valve airtight test bench includes a first station A, characterized in that the first station A includes a test unit A1 and an installation unit A2, and the test unit A1 includes a valve block component 1, Sealing tooling 2, pneumatic two-position four-way reversing valve 4, first pneumatic pressure reducing valve 6 and gas glass rotameter 7; said installation unit A2 includes cylinder 3 and pneumatic three-position five-way reversing valve 5; said The valve block part 1 includes a valve body installation part 101, a tooling installation part 102, a cylinder installation part 103 and a gas discharge port 104; the cylinder 3 includes a cylinder barrel 301 and a piston rod 302; the sealing tooling 2 includes a tooling exhaust part 203 , the tooling fixing part 202, the tooling air intake part 201 and the tooling internal through hole 204.

[0027] The cylinder barrel 301 of the cylinder 3 is fixedl...

Embodiment 3

[0031] Embodiment 3 of the present invention: as Figure 5 As shown, a hydraulic valve airtight test bench includes a first station A, characterized in that the first station A includes a test unit A1 and an installation unit A2, and the test unit A1 includes a valve block component 1, Sealing tooling 2, pneumatic two-position four-way reversing valve 4, first pneumatic pressure reducing valve 6 and gas glass rotameter 7; said installation unit A2 includes cylinder 3 and pneumatic three-position five-way reversing valve 5; said The valve block part 1 includes a valve body installation part 101, a tooling installation part 102, a cylinder installation part 103 and a gas discharge port 104; the cylinder 3 includes a cylinder barrel 301 and a piston rod 302; the sealing tooling 2 includes a tooling exhaust part 203 , the tooling fixing part 202, the tooling air intake part 201 and the tooling internal through hole 204.

[0032] The cylinder barrel 301 of the cylinder 3 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com