LED bulb

A technology of LED light bulbs and LED light sources, applied in the cooling/heating devices of lighting devices, lighting and heating equipment, road vehicles, etc., can solve the problems of low heat dissipation efficiency and slow air flow rate, and improve the flow rate and speed up the convection. The effect of speed, rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

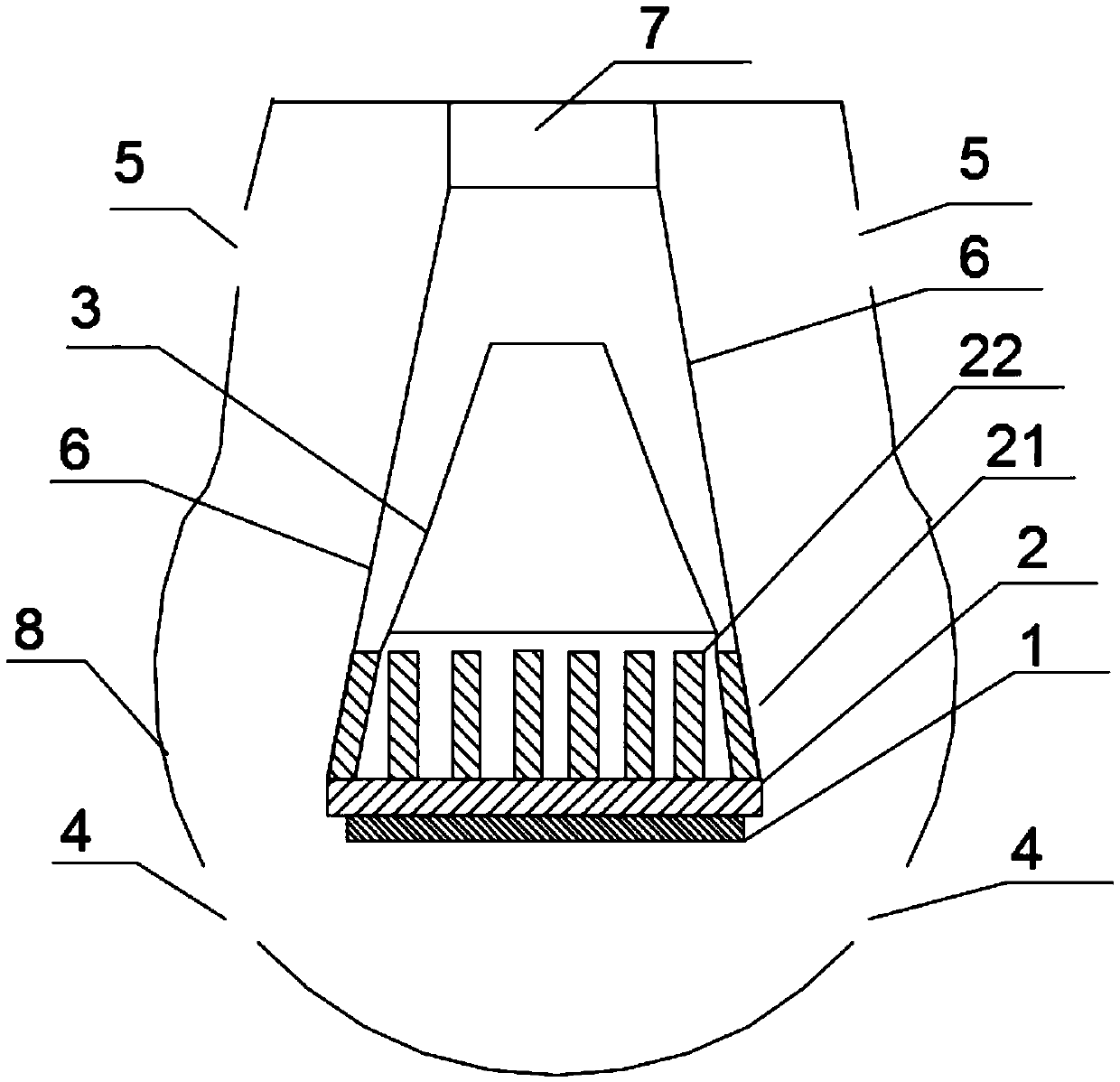

[0012] like figure 1 As shown, this embodiment includes a lamp holder 7, an LED light source 1, a housing 8, and the upper and lower ends of the housing 8 are provided with convection holes. It is fixed on the lamp holder 7, and the upper end surface of the heat dissipation plate 2 has a heat dissipation protrusion 22, and the upper end of the heat dissipation protrusion 22 is fixed with a conical glass sleeve 3, and the housing 8 is located on the upper side of the glass sleeve 3 and has two openings. Convection holes 5 , two lower convection holes 4 are opened on the part of the casing 8 located at the lower side of the LED light source 1 . Both ends of the upper surface of the heat dissipation plate 2 have protrusions 21 inclined toward the center of the heat dissipation plate.

[0013] Since the heat dissipation plate is provided with a protrusion on the end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com