Tensioning device and operation method for high prestressed bolt support in deep roadway

A high-prestressed, bolt-supporting technology, applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the effect of surrounding rock control that affects the quality of support, affects the progress of roadway construction, and the application of high prestressing The efficiency is not high enough to achieve the effect of avoiding bolt damage, improving construction efficiency and overcoming the lack of prestress value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

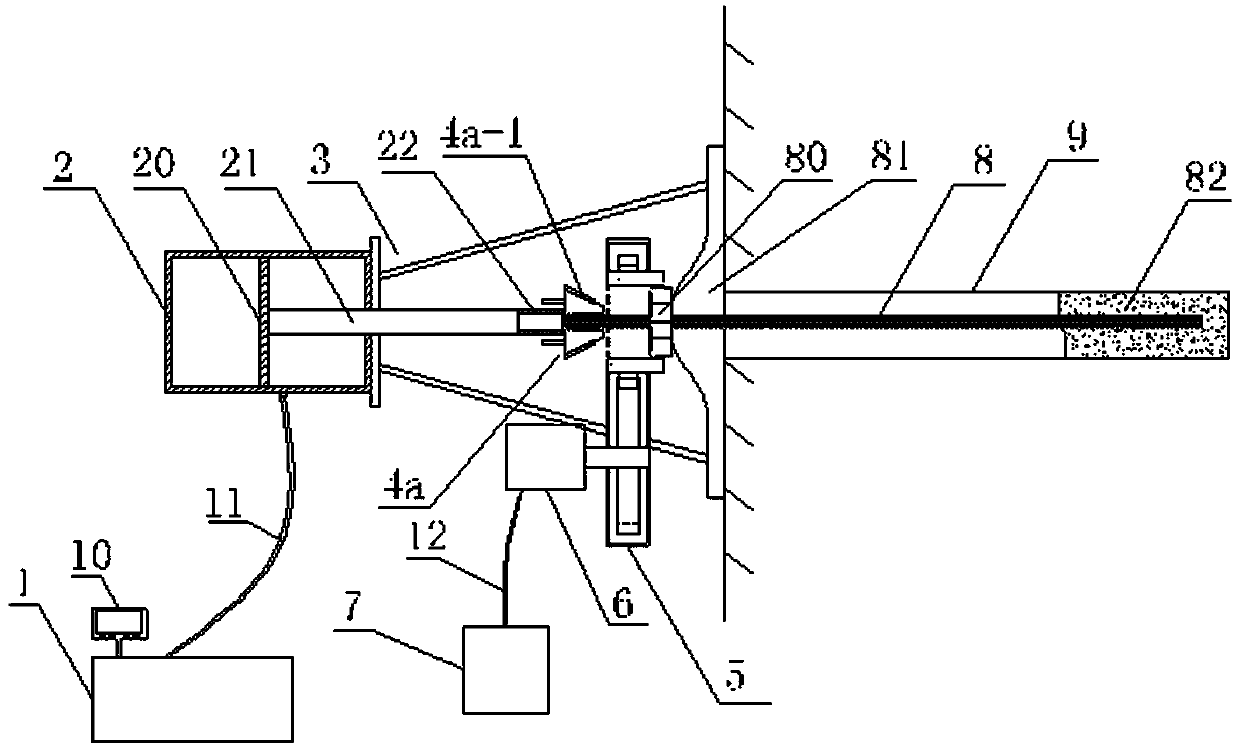

[0042] Such as figure 1 As shown, a tensioning device for high prestressed bolt support in deep roadway, including hydraulic oil pump 1, hydraulic jack 2, tripod support 3 for fixing hydraulic jack 2, hydraulic jack 2 and prestressed The connecting piece 4a used for connecting the end of the anchor rod 8 is used to tighten the fastening nut 80 at the end of the anchor rod 8 with the nut fastening device 5, and the power motor 6 and the power source 7 of the nut fastening device 5 are driven.

[0043] The hydraulic oil pump 1 is connected to the hydraulic jack 2 through the hydraulic pipe 11 to provide power for the hydraulic jack 2 and drive the jack 2 to provide tension prestress for the anchor rod 8; the hydraulic oil pump 1 is equipped with a pressure digital display device 10, which can real-time and accurately Displays the pressure applied to hydraulic jack 2.

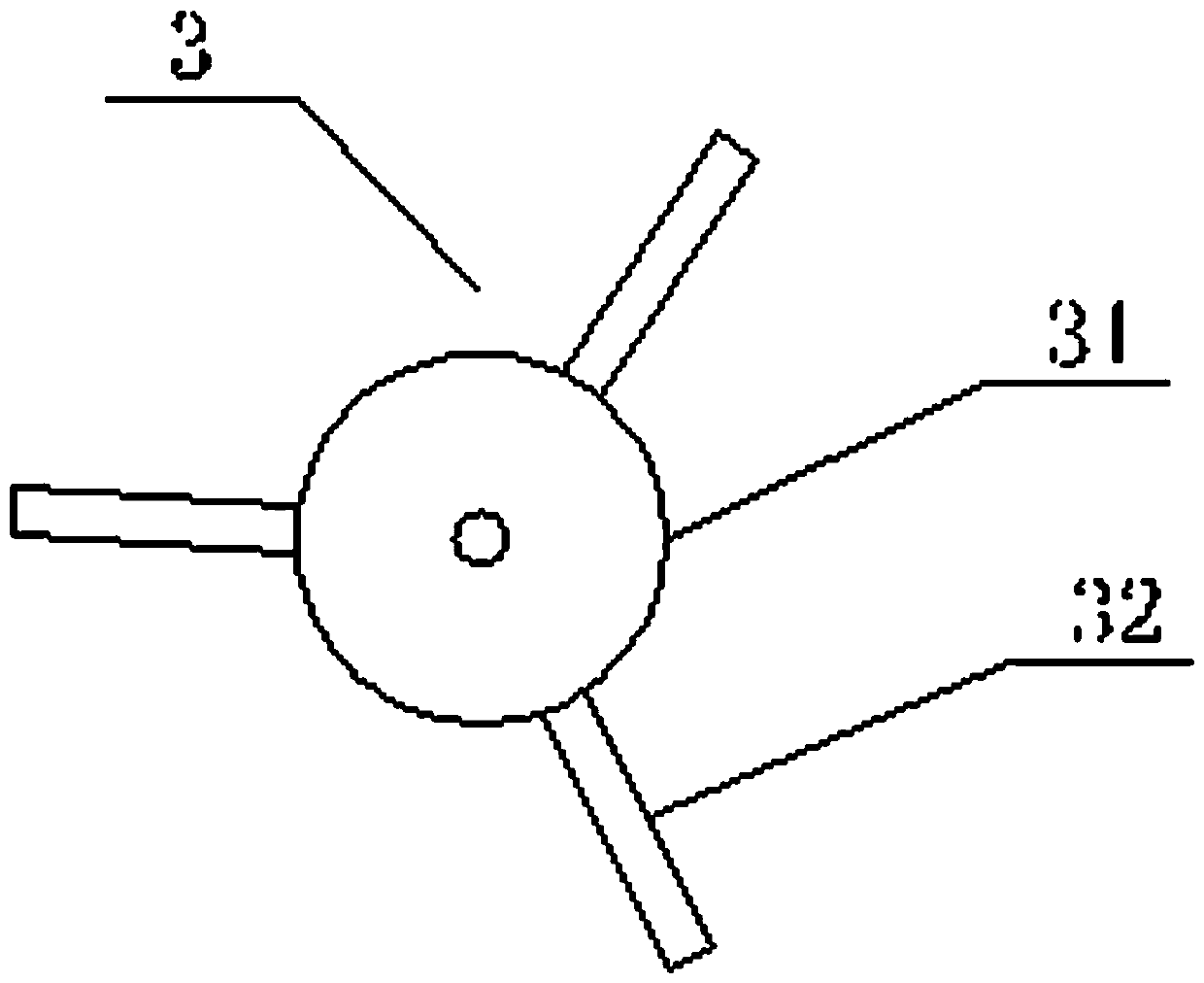

[0044] The shell of the hydraulic jack 2 is fixed on the tripod 3; the hydraulic jack 2 is composed of a cylin...

Embodiment 2

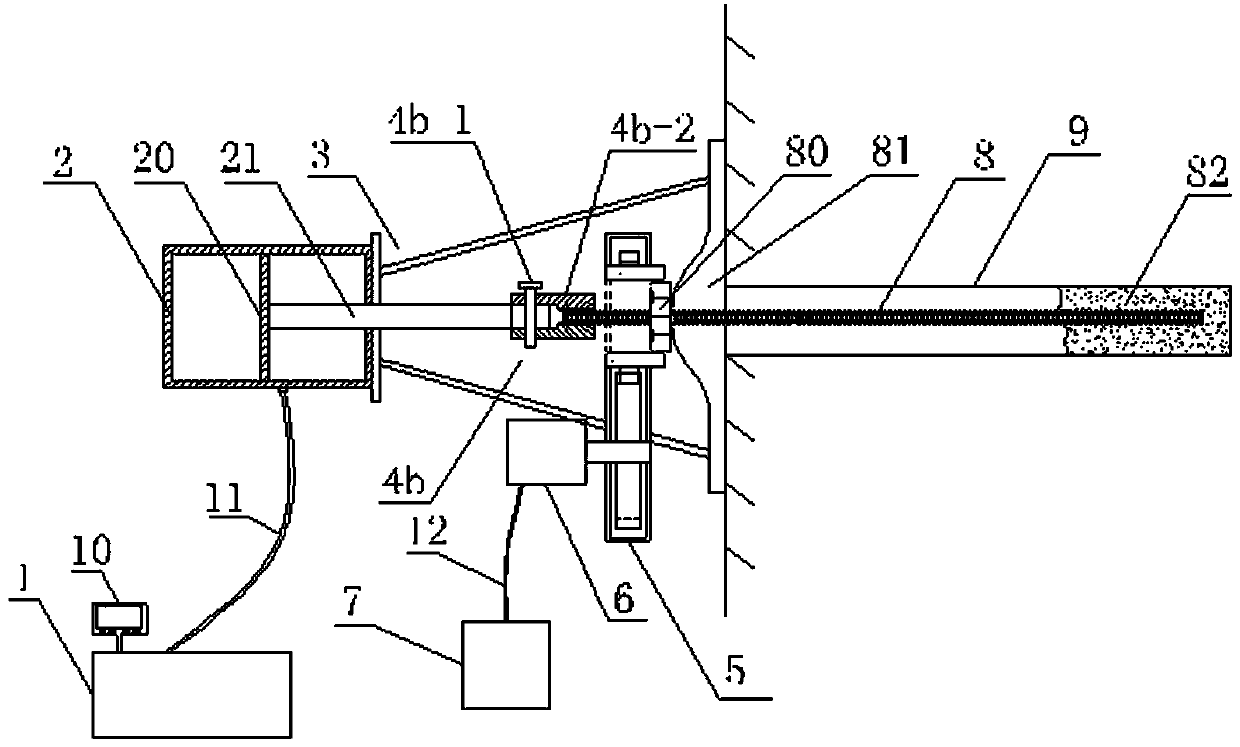

[0056] Such as figure 2 As shown, a tensioning device for high prestressed bolt support in deep tunnels, including a hydraulic oil pump 1, a hydraulic jack 2, a tripod bracket 3 for fixing the hydraulic jack 2, the hydraulic jack 2 and the exposed end of the anchor rod 8 The connecting piece 4b for connection, the nut tightening device 5 for tightening the tightening nut 80, drives the power motor 6 and the power source 7 of the nut tightening device 5.

[0057] The hydraulic oil pump 1 is connected to the hydraulic jack 2 through the hydraulic pipe 11 to provide power for the hydraulic jack 2 and drive the jack 2 to provide tension prestress for the anchor rod 8; the hydraulic oil pump 1 is equipped with a pressure digital display device 10, which can real-time and accurately Displays the pressure applied to hydraulic jack 2.

[0058] The shell of the hydraulic jack 2 is fixed on the tripod 3; the hydraulic jack 2 is composed of a cylinder, a piston 20 and a piston rod 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com