Device special for high strain test of foundation pile

A special device and high-strain technology, which is applied in infrastructure engineering, foundation structure testing, construction, etc., can solve problems affecting test quality, falling weight eccentricity, etc., and achieve the effect of simple use and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

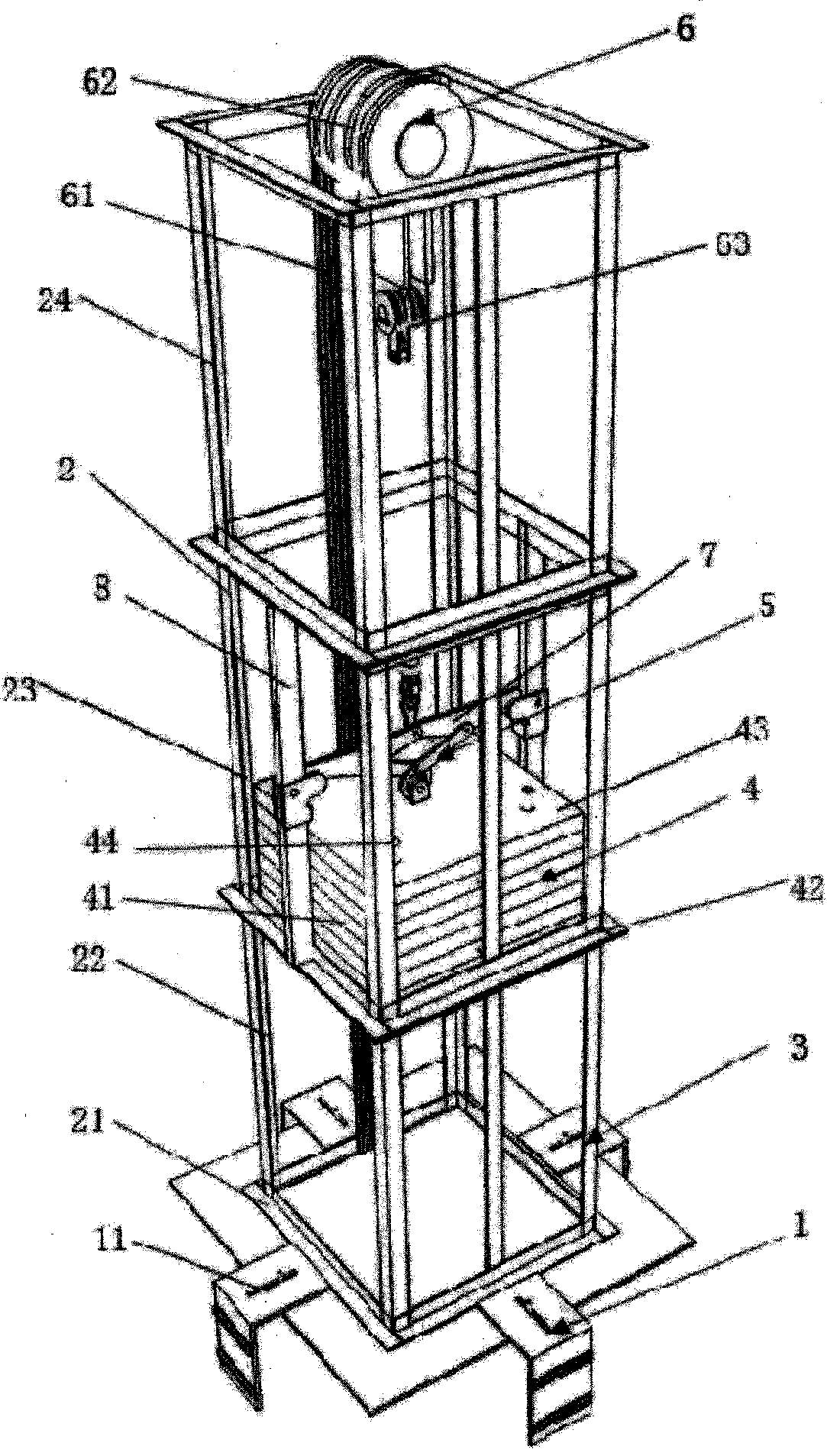

[0017] See figure 1 As shown, a special device for high-strain testing of foundation piles includes a pile head fixing device 1, a guide frame 2 vertically arranged on the pile head fixing device 1, and a guiding drop weight rolling device 3 is arranged in the guide frame 2 in turn. , a combined hammer head 4, an automatic uncoupling device 5 and an electric lifting device 6, the electric lifting device 6 is arranged on the top of the guide frame 2, and an automatic uncoupling device is connected between the guide drop hammer rolling device 3 and the automatic uncoupling device 5 device 5. The combined hammer head 4 is built in the guide frame 2, and it is composed of several steel plates 41, hammer bottom plates 42 and hammer top plates 43. The four corners of the surface have round holes 44 at the same position. The round holes 44 are inserted into the connecting rod. The end expansion of the connecting rod is closely connected with the round hole of the hammer bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com