Cotton web bundling mechanism of intelligent comber

A comber, intelligent technology, applied in the direction of comber, textile and papermaking, fiber processing, etc., can solve the problem of affecting the normal operation of the sliver quality, not effectively improving the cohesion of the sliver, and adversely affecting the mutual interaction of the sliver. Cohesion and other problems, to achieve the effect of convenient sliver accumulation, not easy to loosen, and convenient for subsequent maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

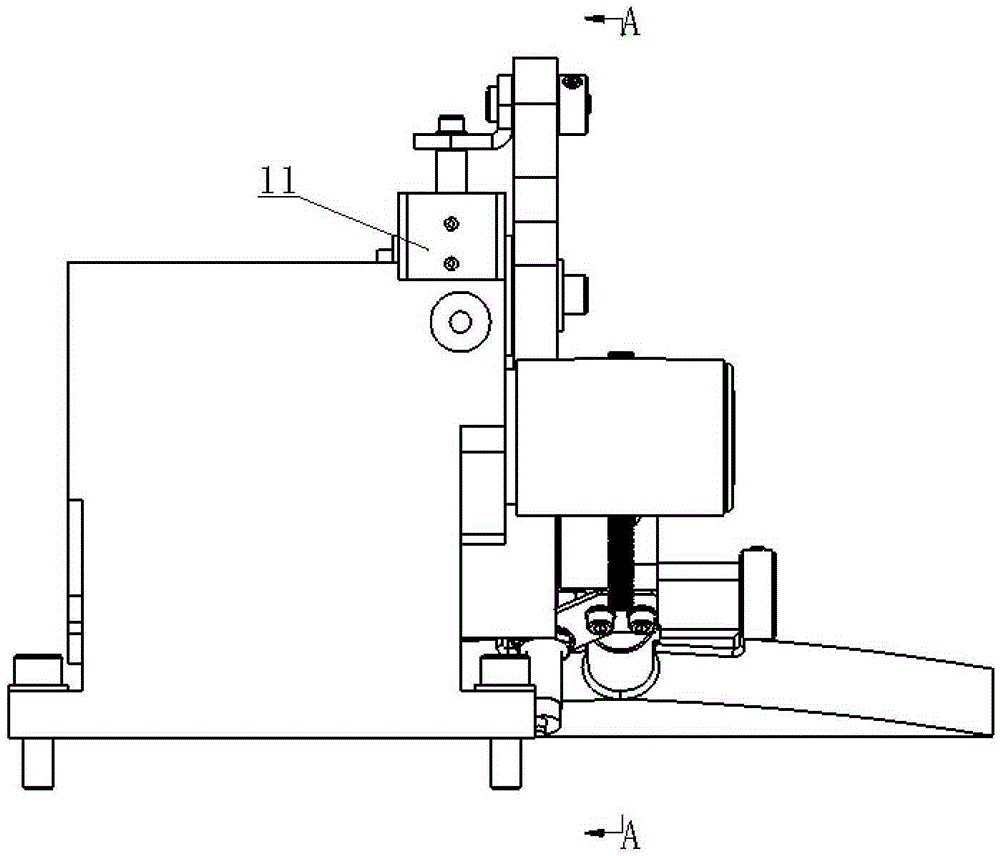

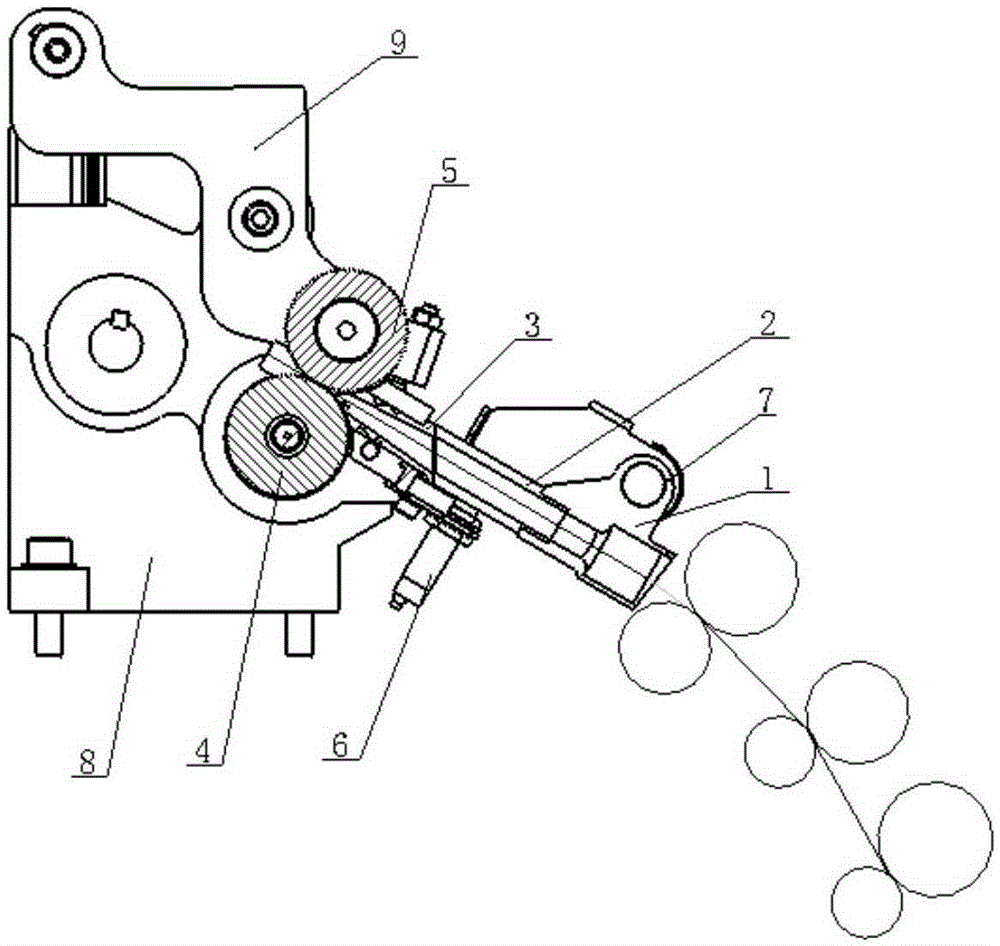

[0020] Embodiment: A cotton web bundling mechanism of an intelligent comber, including the first and second pressure rollers 4 and 5 positioned on the support 8 of the smart comber, a driving device, a gathering pipe 1, a delivery pipe 2 and a bundling horn Port 3, the first and second press rollers 4 and 5 are meshed and driven, the driving device drives the first press roller to rotate, the entrance of the gathering tube 1 is just behind the drafting output roller of the intelligent combing machine, the entrance of the delivery pipe 2 is connected to the gathering tube 1. The outlet is fixedly connected, and the cluster horn mouth 3 is fixedly installed on the intelligent combing machine support 8. The inlet of the cluster horn mouth 3 can be connected with the outlet of the conveying pipe 2. The inner side of the cluster horn mouth 3 is a horn hole 13 whose outlet diameter is smaller than the inlet diameter. The meshing points of the first and second pressure rollers 4 and 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com