Combined polyether, polyurethane foam and its preparation method and application

A technology for combining polyether and polyether polyol, which is applied in the field of combining polyether and polyurethane foam and its preparation, can solve the problems of large pouring amount of power insulating rods, poor foam density distribution, and decreased foam performance, so as to reduce the on-site installation. , high dimensional stability, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

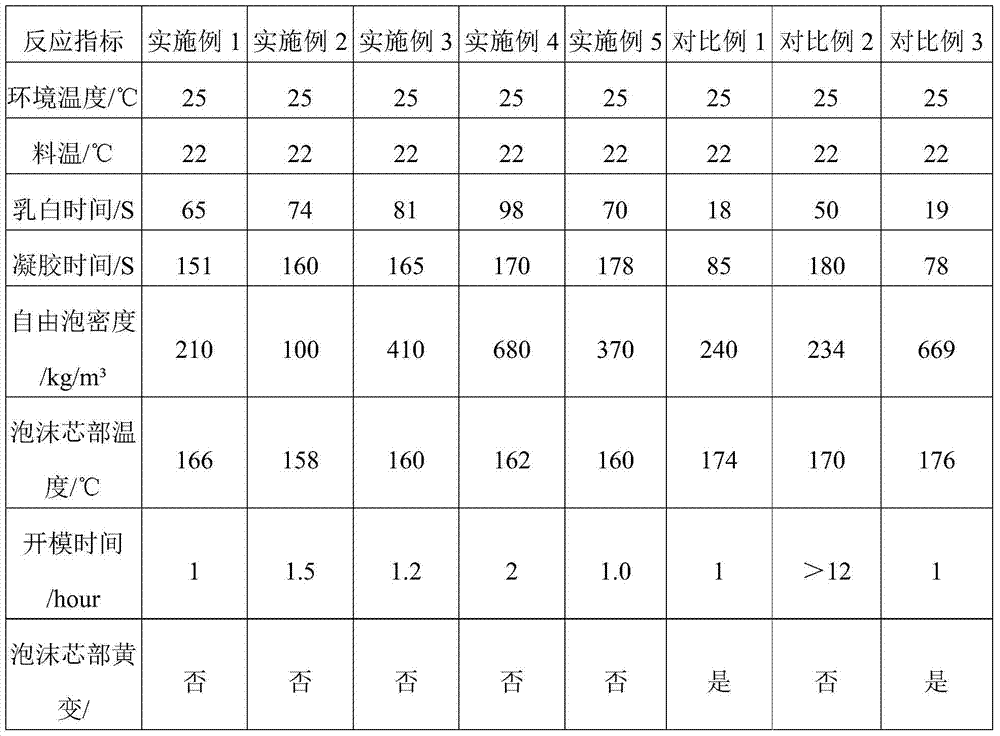

[0033] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

[0034] The parts described in the following examples are all parts by weight.

[0035] In the following examples, the raw material sources used are:

[0036] Polyether polyol A: YD-8350, Hebei Yadong Chemical Group Co., Ltd.;

[0037] Polyether polyol B: SD-7100, Shanghai Dongda Chemical Co., Ltd.;

[0038] Polyester polyol C: PS-3152, Nanjing Jinling Stepan Chemical Co., Ltd.;

[0039] Crosslinking agent: glycerol, Shanghai Lingfeng Chemical Reagent Co., Ltd.;

[0040] Foam stabilizer: L-580, Evonik Degussa (China) Investment Co., Ltd.;

[0041] DabcoLK-221, Air Products;

[0042] Catalyst: JXP-509, Air Products Company;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com