Multi-pipe connecting die for die pressing pipes

A pipe connection and mold technology, applied in the field of multi-pipe connection molds for molded pipes, can solve the problems of weak connection, poor sealing performance, cracking, etc., and achieve the effect of simple and reasonable structure design and easy production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

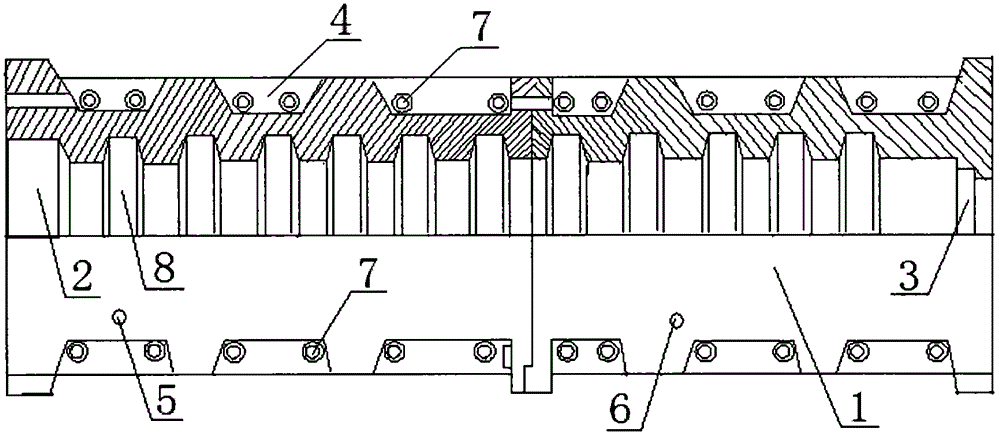

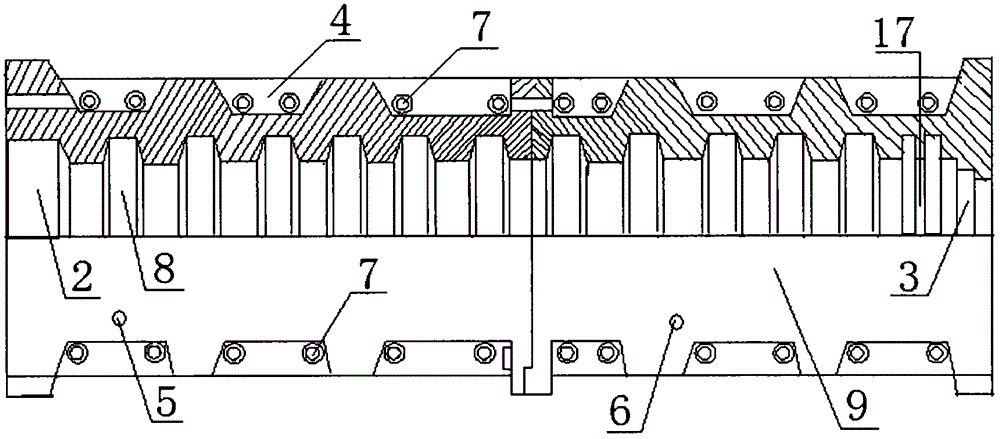

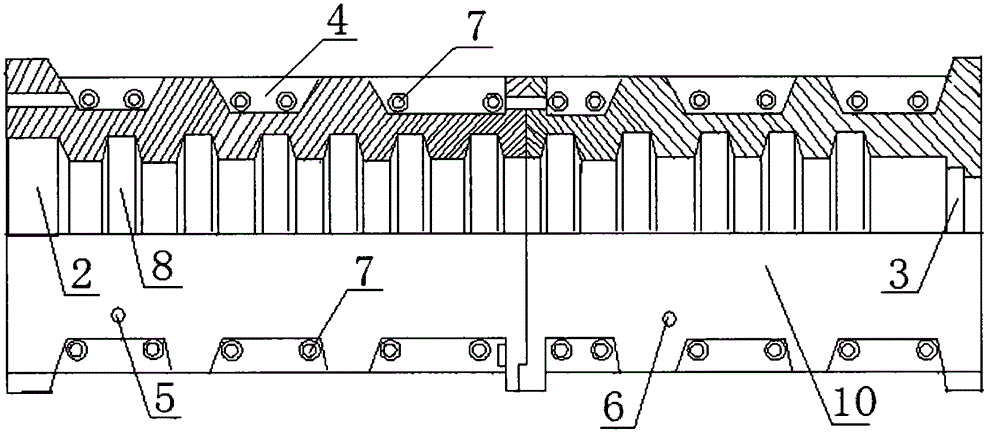

[0025] figure 1 It is the structural representation of the A die of the present invention, figure 2 It is a structural schematic diagram of B die of the present invention, image 3 It is the structural representation of A punch of the present invention, Figure 4 It is the structural representation of the B punch of the present invention, Figure 5 It is the structural representation of C die of the present invention, Image 6 It is a structural schematic diagram of the C concave mold of the present invention.

[0026] Please refer to the accompanying drawings, the molded pipe multi-pipe connection mold provided by the present invention includes a mold A and a mold B, the length of the molded pipe made by the mold A and the mold B is 2 meters after butt joint, and the mould A is formed by the A mold Die 1 and A punch, the B die is composed of B di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com