45-degree-angle and 90-degree-angle switching machining system for stainless steel

A processing system, stainless steel technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of poor operation protection, poor tool precision, low work efficiency, etc., to improve work efficiency and precision, protect operation environment, the effect of improving operational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

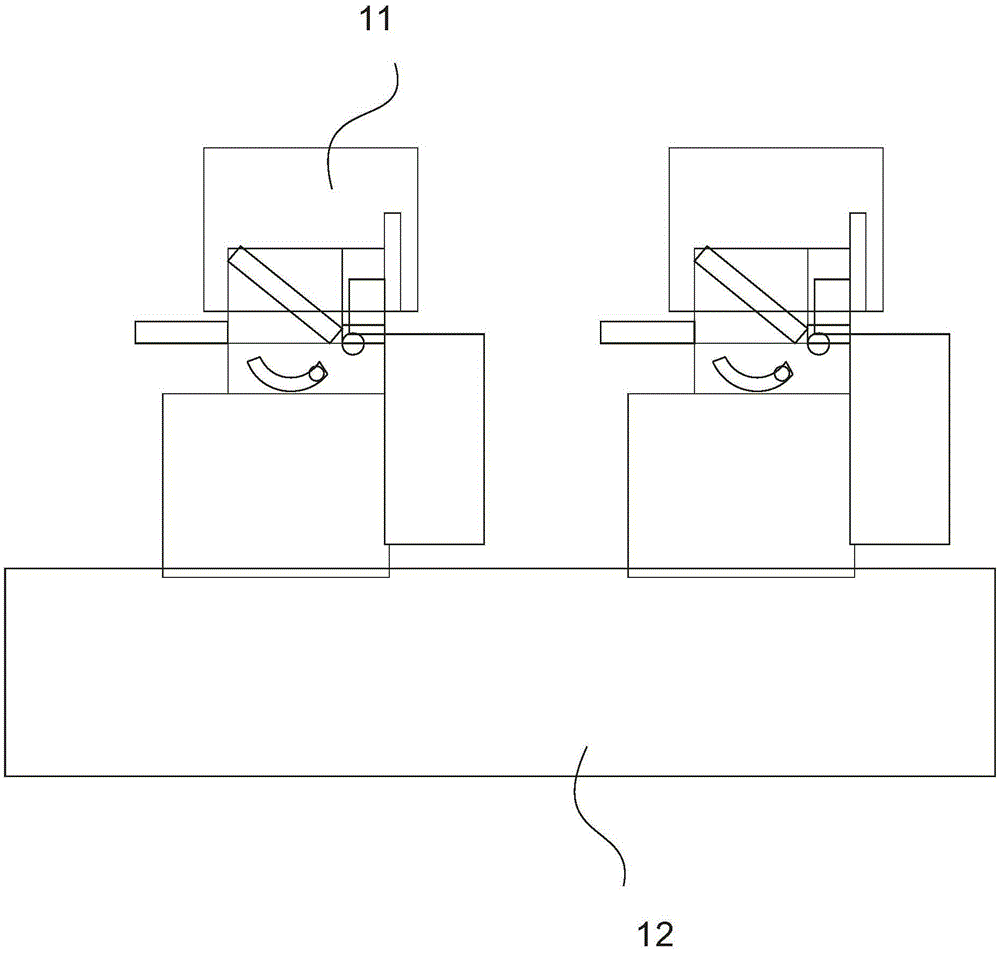

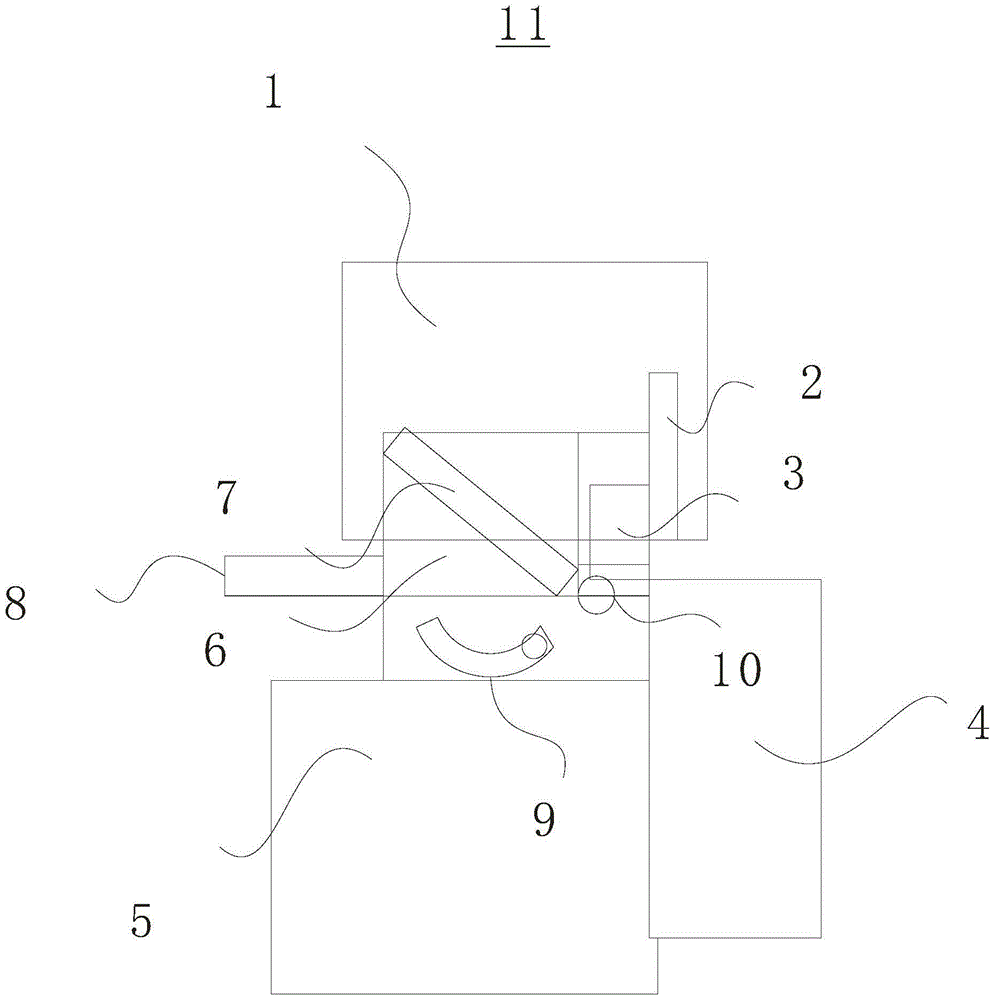

[0012] Such as figure 1 As shown, the present invention includes two angle-switching stainless steel processing tables 11 that are arranged on crawler belts 12 and move along the crawler belts. It is connected with the workbench through the piston 2 and covers the protective cover 1 on the upper end of the switchable tool holder. The workbench on one side of the switchable toolholder is provided with a two-dimensional piston fixing frame 3. The two-dimensional piston fixing frame includes a The piston rod that moves downward and is perpendicular to the switching tool seat and moves toward the switching tool seat. The switching tool seat includes a seat frame, and a seat body hinged with the seat frame through a hinge sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com