A form milling cutter with tool setting structure

A technology for forming milling cutters and tool setting tables, which is applied to milling cutters, milling machine equipment, and details of milling machine equipment. It can solve problems that affect processing efficiency, difficulty in tool setting, and difficult machining quality, so as to reduce skill requirements and reduce tool setting. The effect of reducing the workload and reducing the tool setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The form milling cutter with tool setting structure of the present invention will be further described below through examples and with reference to the accompanying drawings.

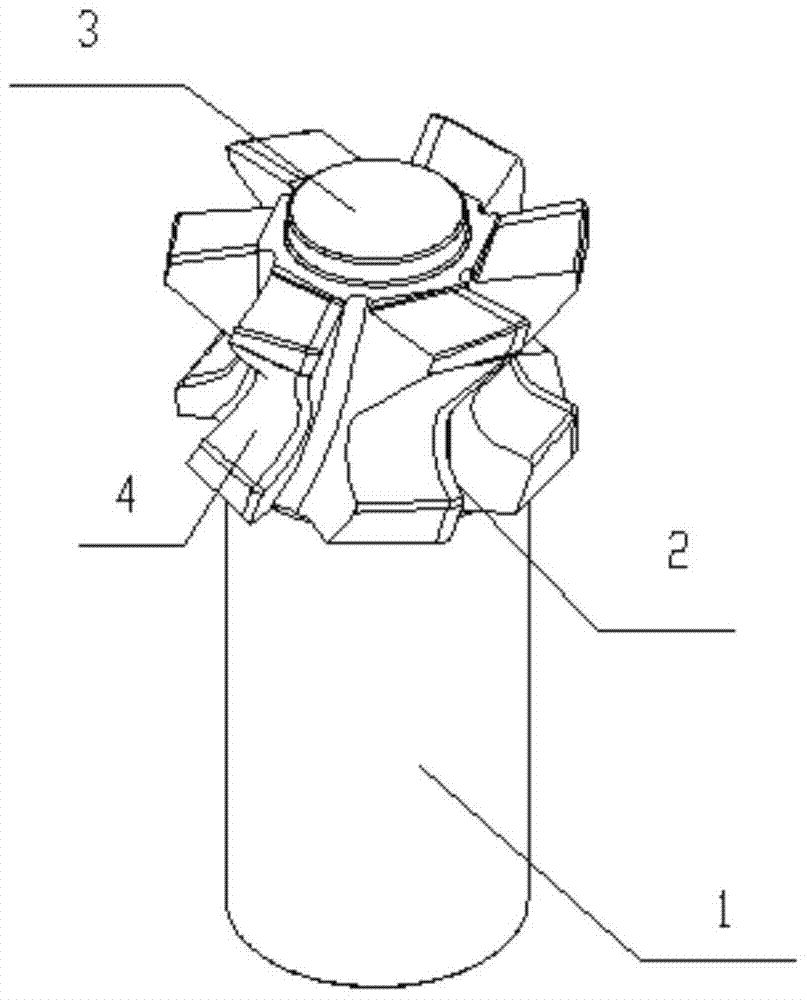

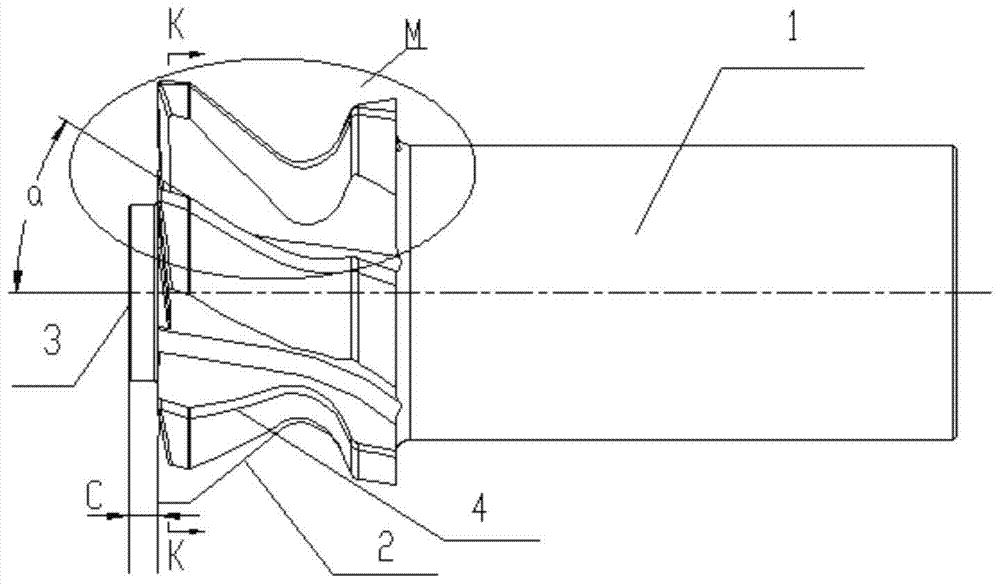

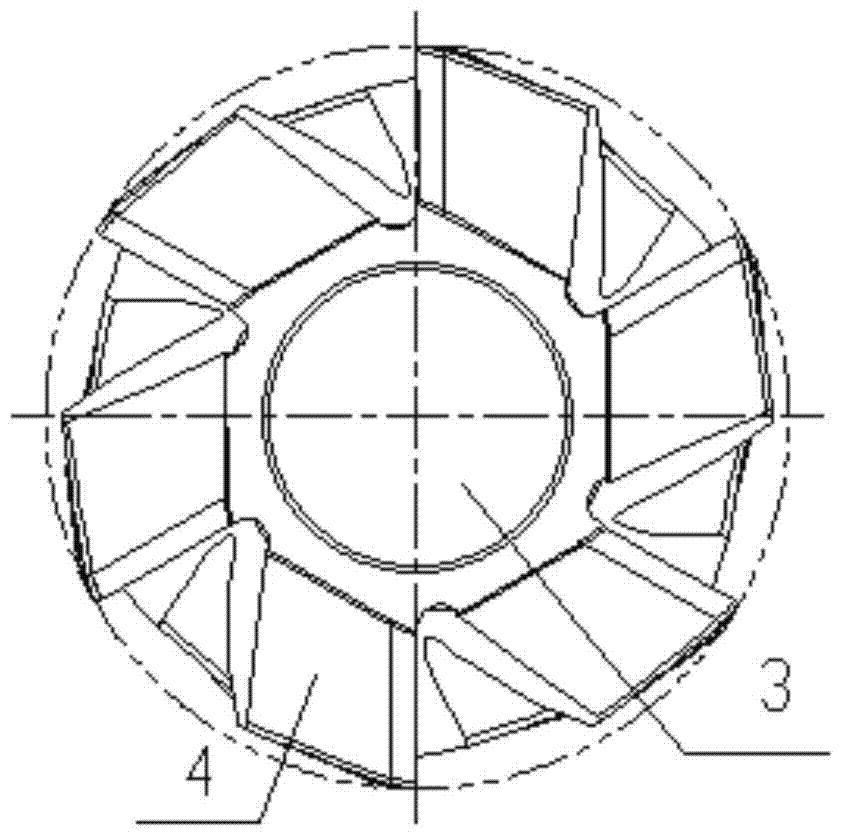

[0023] In this embodiment, the forming milling cutter with tool setting structure is as figure 1 , figure 2 , image 3 As shown, it consists of a cutter bar 1, a cutter disc 4 and a tool setting table 3. The cutter bar 1 is cylindrical, and the cutter disc 4 is provided with six cutter teeth, and each cutter tooth surrounds the cutter disc 4 The center lines of the center lines are equiangularly distributed. The tool setting table 3 is in the shape of a truncated cone. The center lines of the tool rest 3 are the same straight line.

[0024] The form milling cutter with tool setting structure in this embodiment is used for processing Image 6 The blade tenon 5 with an asymmetrical pressure surface is shown. The material of the blade tenon is stainless steel. The angle between the basin pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com