Novel adjustable ejector

An adjustable, ejector technology, applied in the direction of ejector, ejector, liquid ejector, etc., can solve the problems of single parameter, inability to adjust the structural parameters of ejector, and great influence on the performance of ejector refrigeration system, and achieve increased stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

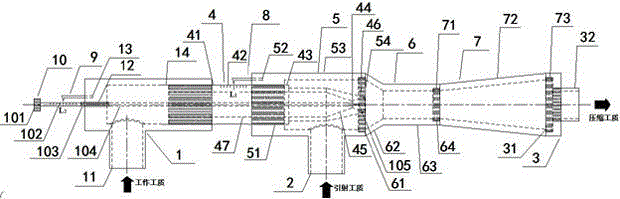

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

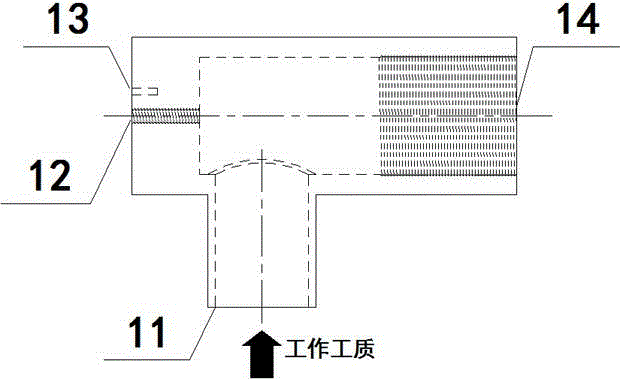

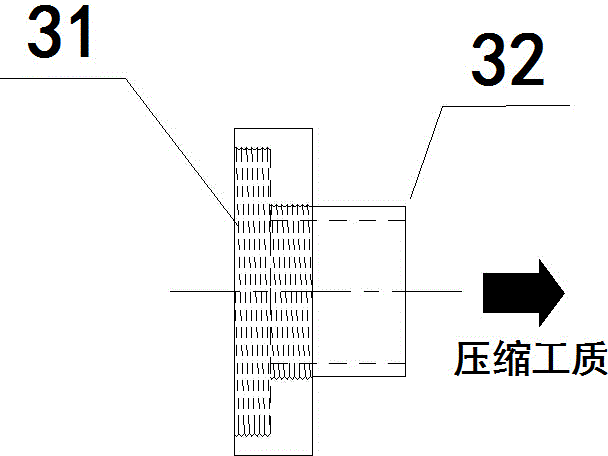

[0020] like figure 1 As shown, the nozzle 4 is connected to the working fluid inlet 1 and the suction chamber 5 through threads, and the direction of the two threads is the same. When adjusting the distance from the outlet of the nozzle 4 to the inlet of the mixing chamber 6, it is only necessary to rotate the nozzle 4 so that Axial movement does not need to change the relative position between the working fluid inlet 1 and the suction chamber 5. Therefore, the operation is simple and convenient. At the same time, there is a scale in the middle of the nozzle, which can easily read the nozzle 4 of the new adjustable injector. The distance from the outlet to the inlet of the mixing chamber 6. When the needle 81 of the distance measuring needle a8 points to L on the scale a42 1 scale value, it indicates that the new injector is in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com