Xiao'er Feireping capsule and preparation method thereof

A lung-heat, pediatric technology, applied in capsule delivery, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of slow disintegration, unsatisfactory curative effect, and low curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

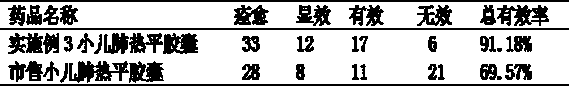

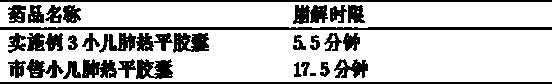

Examples

Embodiment 1

[0033] Take 45g of patchouli, 80g of pomegranate peel, 39g of Xinyi, 3.3g of bezoar, 55g of earthworm, 9.9g of pearl, 44g of fistula, 55g of fritillaria, 0.27g of musk, 44g of coptis, 88g of scutellaria, 1g of antelope horn, 0.55 of borneol g, Lithospermum 39g, Bupleurum 55g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 16Mpa, extraction temperature 20℃, separator pressure 12Mpa, separator temperature 37℃, separation time 2.0 hours, The carbon dioxide flow rate is 23L per hour, and the extract is obtained; the extract is dried under reduced pressure at 61°C to obtain a dry paste; the dry paste is added with 150 g of mannitol, and the mixture is pulverized into a mixed dry paste powder with a particle size of 200-300 nm using a high-energy nano impact mill; Mixed dry paste powder, microcrystalline cellulose 45g, cross-linked polyvinylpyrrolidone 45g, croscarmellose sodium 35g, mix well, wet granulation with 50% etha...

specific Embodiment 2

[0035] Take 45g of patchouli, 80g of pomegranate peel, 39g of Xinyi, 3.3g of bezoar, 55g of earthworm, 9.9g of pearl, 44g of fistula, 55g of fritillaria, 0.27g of musk, 44g of coptis, 88g of scutellaria, 1g of antelope horn, 0.55 of borneol g, Lithospermum 39g, Bupleurum 55g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 41Mpa, extraction temperature 39℃, separator pressure 19Mpa, separator temperature 57℃, separation time 3.5 hours, The flow rate of carbon dioxide is 34L per hour to obtain the extract; take the extract and dry under reduced pressure at 77°C to obtain a dry paste; add 200g of mannitol to the dry paste and pulverize into a mixed dry paste powder with a particle size of 200-300nm using a high-energy nano-impact mill; take Mixed dry paste powder, microcrystalline cellulose 55g, cross-linked polyvinylpyrrolidone 55g, croscarmellose sodium 45g, mix well, wet granulation with 70% ethanol, dry at 80°C, add...

Embodiment 3

[0037] Take 45g of patchouli, 80g of pomegranate peel, 39g of Xinyi, 3.3g of bezoar, 55g of earthworm, 9.9g of pearl, 44g of fistula, 55g of fritillaria, 0.27g of musk, 44g of coptis, 88g of skullcap, 1g of antelope horn, 0.55 of borneol g, Lithospermum 39g, Bupleurum 55g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 28Mpa, extraction temperature 30℃, separator pressure 15Mpa, separator temperature 47℃, separation time 3 hours, The flow rate of carbon dioxide is 28L per hour to obtain the extract; take the extract and dry under reduced pressure at 69°C to obtain a dry paste; take the dry paste and add 175g of mannitol, and use a high-energy nano-impact mill to pulverize into a mixed dry paste powder with a particle size of 200-300nm; take Mixed dry paste powder, microcrystalline cellulose 50g, cross-linked polyvinylpyrrolidone 50g, croscarmellose sodium 40g, mix well, wet granulation with 60% ethanol, dry at 70°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com