A safety valve aging detection method and detection tool for lead-acid batteries

A lead-acid battery and testing tooling technology, applied in the field of testing, can solve the problems of sticking between the valve body and the valve seat, reducing the battery cycle life, and failing to open the opening pressure of the safety valve, so as to achieve high reliability, avoid premature termination, and prevent The effect of qualified safety valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

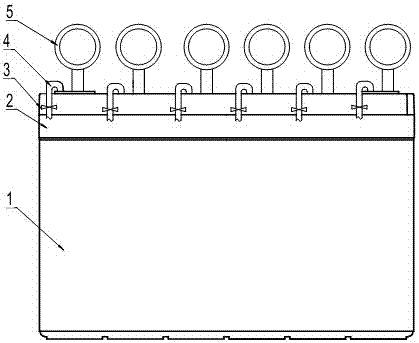

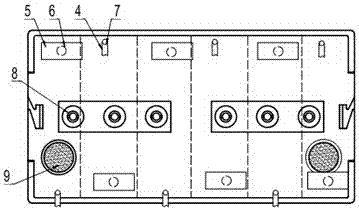

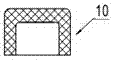

[0024] The safety valve is a rubber product, and its structure is as follows: image 3 shown. The installation method of the safety valve is to buckle it on the valve seat by means of interference fit, weld the cover piece on the air passage, keep a distance of about 0.5mm between the top of the safety valve and the upper cover piece, when the internal pressure of the pole group is too large, the safety The valve slides up to the position of the cover piece, the lower part of the safety valve is opened to release air, and when the air pressure drops to a certain level, the safety valve closes. During the aging process of the safety valve, the performance gradually declines and the use value gradually loses. On the one hand, the safety valve is subjected to mechanical stress for a long time, which accelerates the aging of the rubber; on the other hand, during the use of the battery, most of the time inside the cell is in a negative pressure state, and the safety valve is close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com