Automatic rapid clamping device for motor tests and use method of automatic rapid clamping device

A clamping device and motor testing technology, which is applied in the direction of motor generator testing, measuring devices, measuring device casings, etc., can solve the problems of high cost, complicated control, slow speed, etc., and achieve compact structure, small size and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

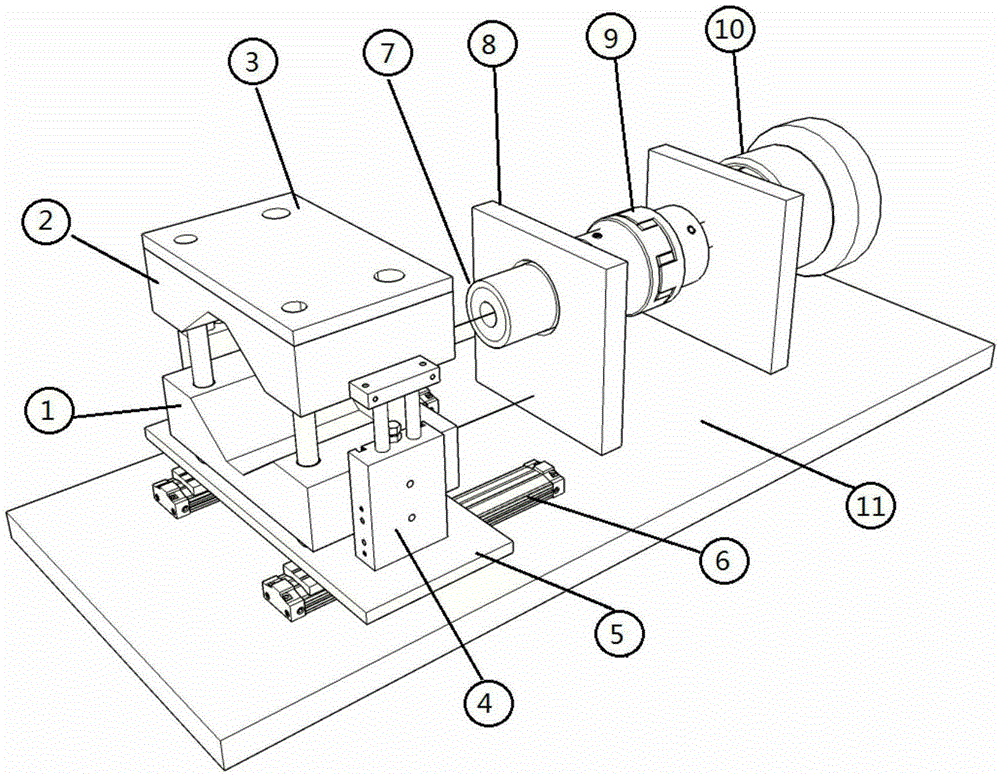

[0034] An automatic quick clamping device for motor testing, please refer to the attached Figure 1-3 , including: a base plate platform 11, and an adjustable motor fixing module and an arbitrary angle plug-in shaft connection structure arranged on the base plate platform,

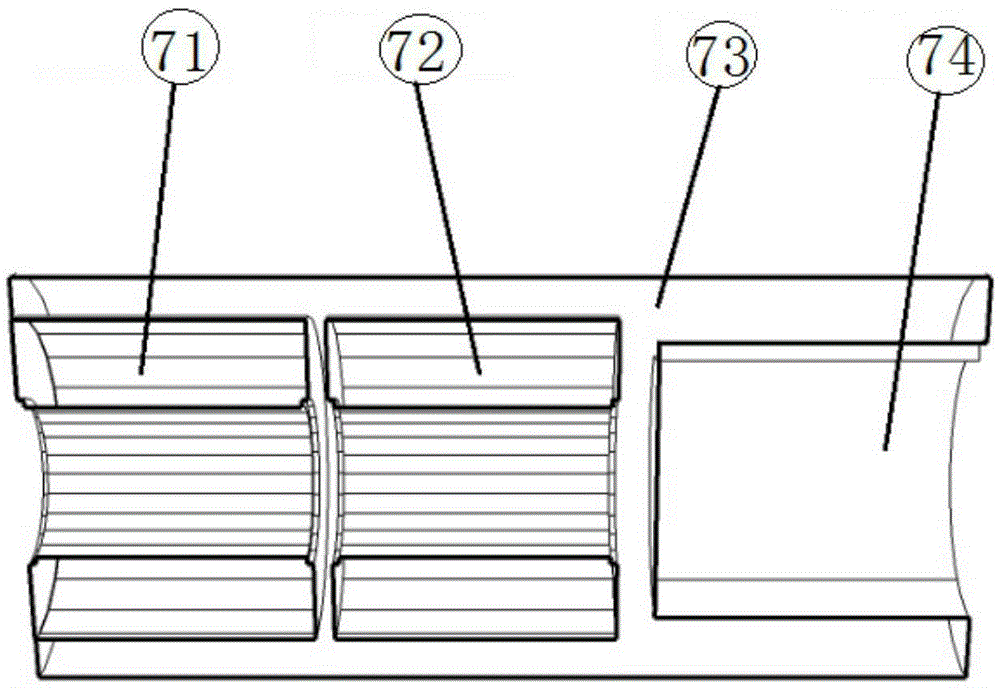

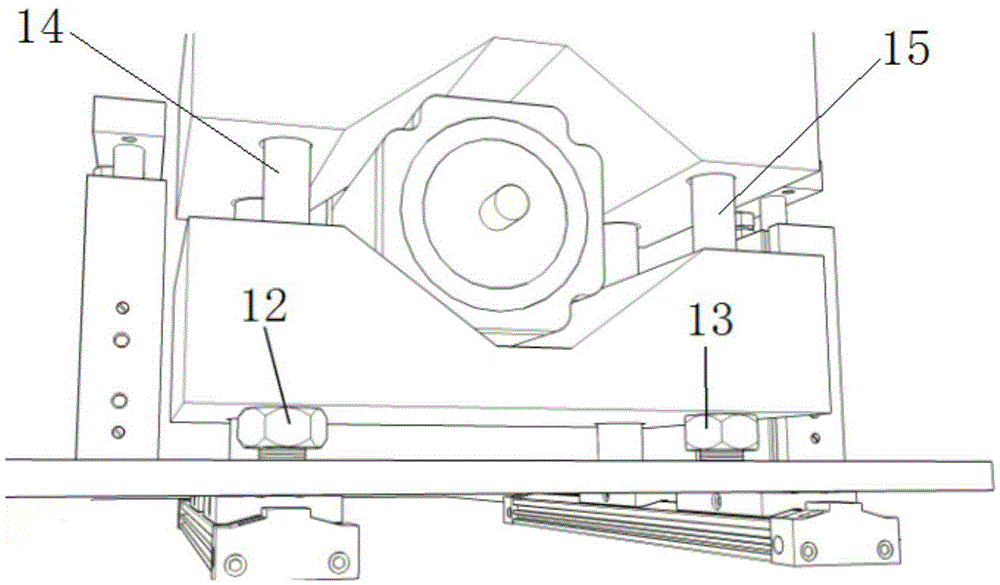

[0035] Wherein, the adjustable motor fixing module includes a V-shaped locking block lower structure 1 for locking the motor, a V-shaped locking block upper structure 2, a locking block top plate 3, a clamping function cylinder 4, and an adjustable motor fixing module. Substrate 5, pneumatic sliding table guide rail 6; the clamping function cylinder pulls down the upper structure of the V-shaped lock block so that a clamping force is generated between the upper and lower structures of the V-shaped lock bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com