A preparing and loading method of a broken rock test sample

A technology for crushing rock and rock, applied in the field of crushed rock sample preparation and loading, can solve problems such as difficulty in sample processing, rock sample crushing, rock sample size deviation, etc., and achieve accurate and reliable test results and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

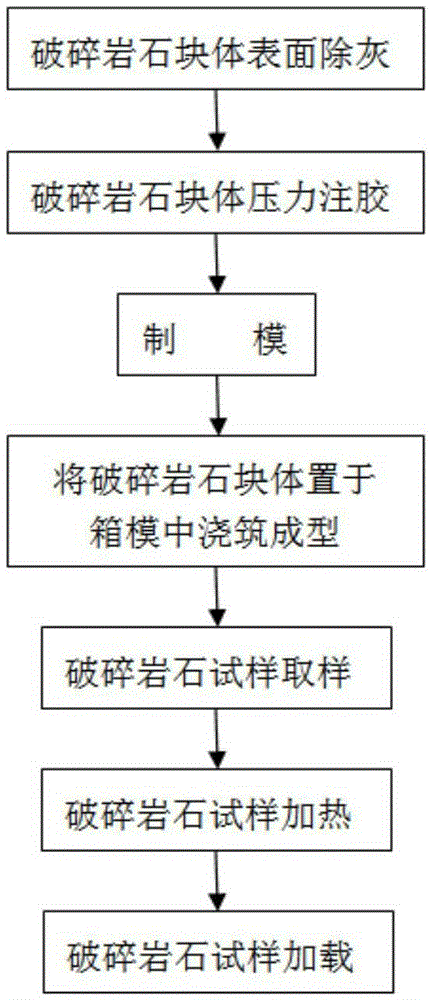

Method used

Image

Examples

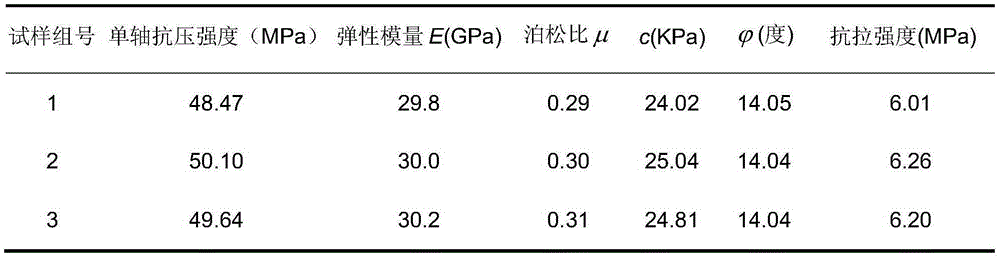

Embodiment 1

[0039] (1) Ash removal on the surface of the broken shale block;

[0040] (2) Inject glue into the broken shale block, the glue used is 307 unsaturated polyester resin, and its heat distortion temperature is 52°C. The pressure injection time is 6 minutes; place the broken rock block in the pressure barrel of the glue filling machine, and perform pressure injection on the broken rock block. After the completion, let it stand at room temperature for 60 minutes;

[0041] (3) The mold making mold is a self-made cuboid wooden box, and its size is 40×40×50cm;

[0042] (4) Fix the broken shale rock block in the box mold by using the method of cushioning gravel, pour C15 low-strength concrete into shape, and leave it to stand for 7 days after pouring into shape;

[0043] (5) Sampling of broken shale rock samples;

[0044] (6) Use an oven to heat the broken rock sample to 52°C, so that the unsaturated polyester resin in the rock sample reaches its thermal deformation temperature, and...

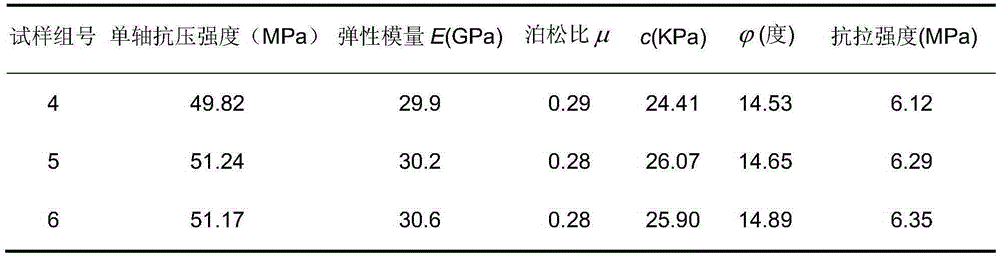

Embodiment 2

[0047] (1) Ash removal on the surface of the broken shale block;

[0048] (2) Inject glue into the broken shale block, the glue used is 307 unsaturated polyester resin, and its heat distortion temperature is 50°C. The pressure injection time is 10 minutes; place the broken rock block in the pressure barrel of the glue filling machine, and perform pressure injection on the broken rock block. After the completion, let it stand at room temperature for 30 minutes;

[0049] (3) The mold making mold is a self-made cuboid wooden box, and its size is 40×40×50cm;

[0050] (4) Fix the broken shale rock block in the box mold by using the method of cushioning gravel, pour C15 low-strength concrete into shape, and leave it to stand for 5 days after pouring into shape;

[0051] (5) Sampling of broken shale rock samples;

[0052] (6) Use an oven to heat the broken rock sample to 50°C, so that the unsaturated polyester resin in the rock sample reaches its thermal deformation temperature, an...

Embodiment 3

[0055] (1) Ash removal on the surface of the broken shale block;

[0056] (2) Inject glue into the broken shale block, the glue used is 307 unsaturated polyester resin, and its heat distortion temperature is 60°C. The pressure injection time is 5 minutes; place the broken rock block in the pressure barrel of the glue filling machine, and perform pressure injection on the broken rock block. After the completion, let it stand at room temperature for 90 minutes;

[0057] (3) The mold making mold is a self-made cuboid wooden box, and its size is 40×40×50cm;

[0058] (4) Fix the broken shale rock block in the box mold by using the method of cushioning gravel, pour C15 low-strength concrete into shape, and let it stand for 3 days after pouring into shape;

[0059] (5) Sampling of broken shale rock samples;

[0060] (6) Use an oven to heat the broken rock sample to 60°C, so that the unsaturated polyester resin in the rock sample reaches its thermal deformation temperature, and redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com