Integrated piezoelectric type universal impact sensor and manufacture method for piezoelectric sensing member

A technology that integrates piezoelectric and sensitive components. It is applied to the measurement, instrument, force/torque/work meter, etc. of the properties of piezoelectric devices, which can solve the problems of single detection direction, low integration and low sensitivity. , to achieve the effect of high natural frequency, high technical index and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

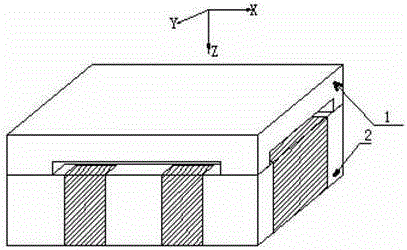

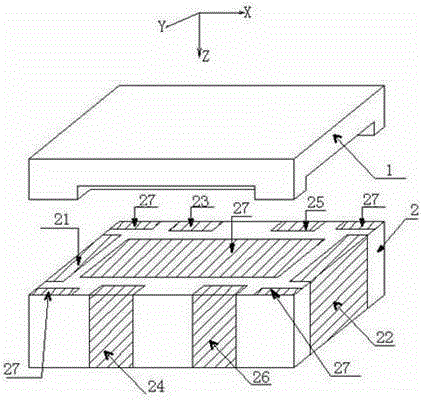

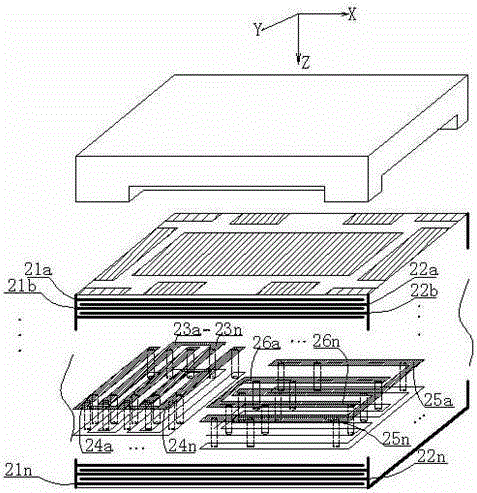

[0052] As a preferred embodiment of the present invention, with reference to the attached figure 1 , 2 and 3, this example discloses

[0053] An integrated piezoelectric universal impact sensor, including a mass block 1 and a piezoelectric sensitive element 2, the piezoelectric sensitive element 2 is provided with a Z-axis axial pressure sensitive output electrode pair 21 / 22, a Y-axis axial pressure Sensitive output electrode pair 23 / 24, X-axis axial pressure sensitive output electrode pair 25 / 26 and mass block welding electrode 27; the mass block 1 is welded on the top of the piezoelectric sensitive element 2 through the mass block welding electrode 27; The direction perpendicular to the axis of the sensitive element 2 is defined as the Z axis, the horizontal direction perpendicular to the Z axis is defined as the X axis, and the direction perpendicular to the plane formed by the X axis and the Z axis is defined as the Y axis.

Embodiment 2

[0055] As another preferred embodiment of the present invention, with reference to the attached figure 1 , 2 and 3, this embodiment discloses:

[0056] An integrated piezoelectric universal impact sensor, including a mass block 1 and a piezoelectric sensitive element 2, the piezoelectric sensitive element 2 is provided with a Z-axis axial pressure sensitive output electrode pair 21 / 22, a Y-axis axial pressure Sensitive output electrode pair 23 / 24, X-axis axial pressure sensitive output electrode pair 25 / 26 and mass block welding electrode 27; the mass block 1 is welded on the top of the piezoelectric sensitive element 2 through the mass block welding electrode 27; The direction perpendicular to the axis of the sensitive element 2 is defined as the Z axis, the horizontal direction perpendicular to the Z axis is defined as the X axis, and the direction perpendicular to the plane formed by the X axis and the Z axis is defined as the Y axis.

[0057] The Z-axis axial pressure-se...

Embodiment 3

[0060] As another preferred embodiment of the present invention, with reference to the attached figure 1 , 2 and 3, this embodiment is a further supplement and illustration made on the basis of embodiment 2. In this embodiment, the Z-axis axial pressure-sensitive output electrode pair 21 / 22 is distributed on the left and right sides of the piezoelectric sensitive element 2 end; the X-axis axial pressure-sensitive output electrode pair 25 / 26 is distributed on the left end of the front and rear sides of the piezoelectric sensitive element 2; the Y-axis axial pressure-sensitive output electrode pair 23 / 24 is distributed on the piezoelectric sensitive element 2 The right end of the front and rear sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com