A low-grade heat source driven jet refrigeration system and refrigeration method

A low-grade heat source and refrigeration system technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large heat dissipation and external dimensions of the condenser, insufficient use of heat, and reduced heat source utilization efficiency. Achieve the effects of improving heat source utilization efficiency, reducing high dependence characteristics, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

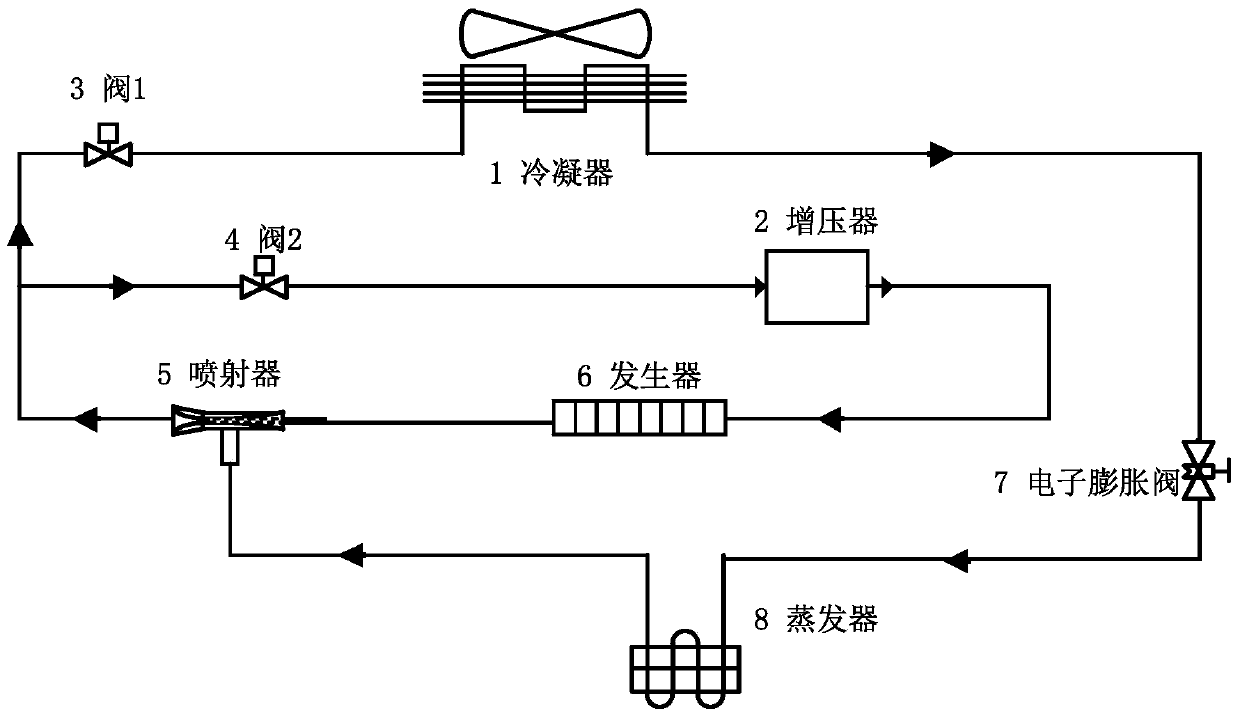

[0027] Such as figure 1 As shown, an ejector refrigeration system driven by a low-grade heat source includes a generator 6, an evaporator 8, a flow control valve, a condenser 1, an ejector 5, an electronic expansion valve 7 and a supercharger 2. The primary flow of the ejector 5 is the output of the generator 6 , and the secondary flow is the output of the evaporator 8 . The output end of the ejector 5 is divided into two paths, one path is the input end of the condenser 1, and the other path is recirculated into the generator 6 through the supercharger 2. The output end of the condenser 1 is connected with the input end of the evaporator 8 via the electromagnetic expansion valve 7 . That is, the input end of the evaporator 8 is the output end of the electromagnetic expansion valve 7 , and the input end of the electromagnetic expansion valve 7 is the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com