Electric connecting member

一种电连接件、电连接的技术,应用在连接、连接装置的零部件、电气元件等方向,能够解决生产效率低、过程费时繁琐、不利自动化生产等问题,达到安装简便、结构简单、便于自动化组装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is elaborated below by specific embodiment:

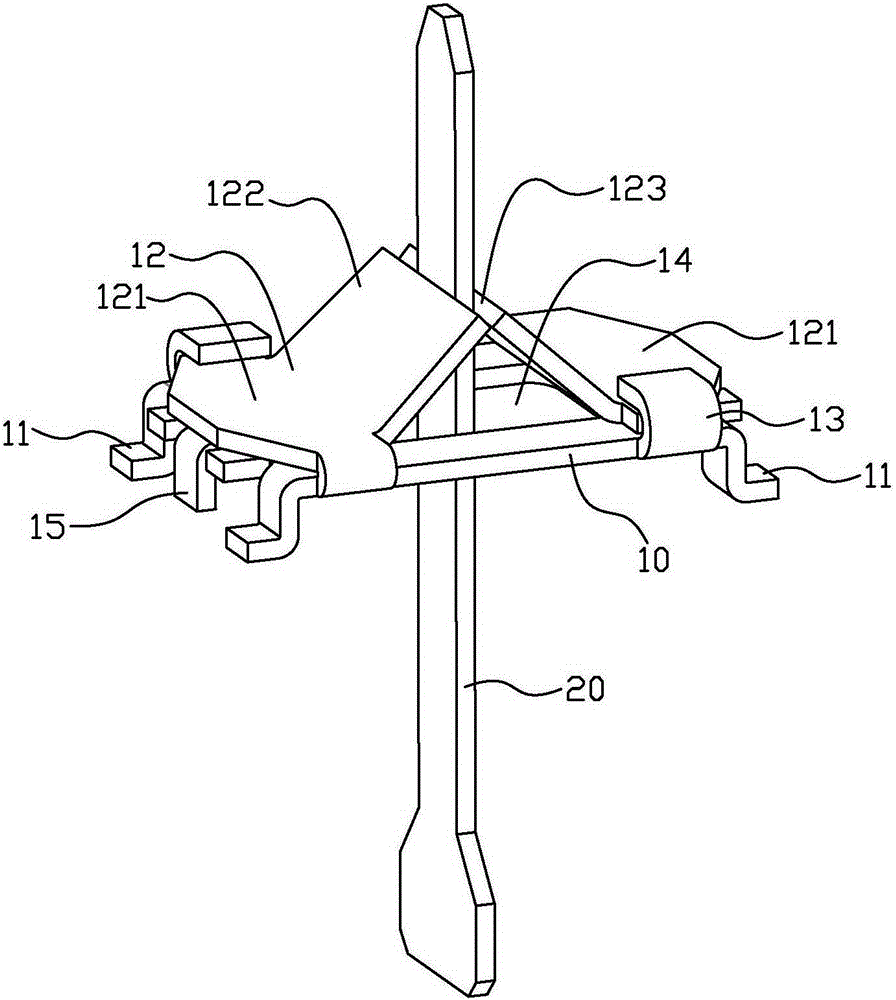

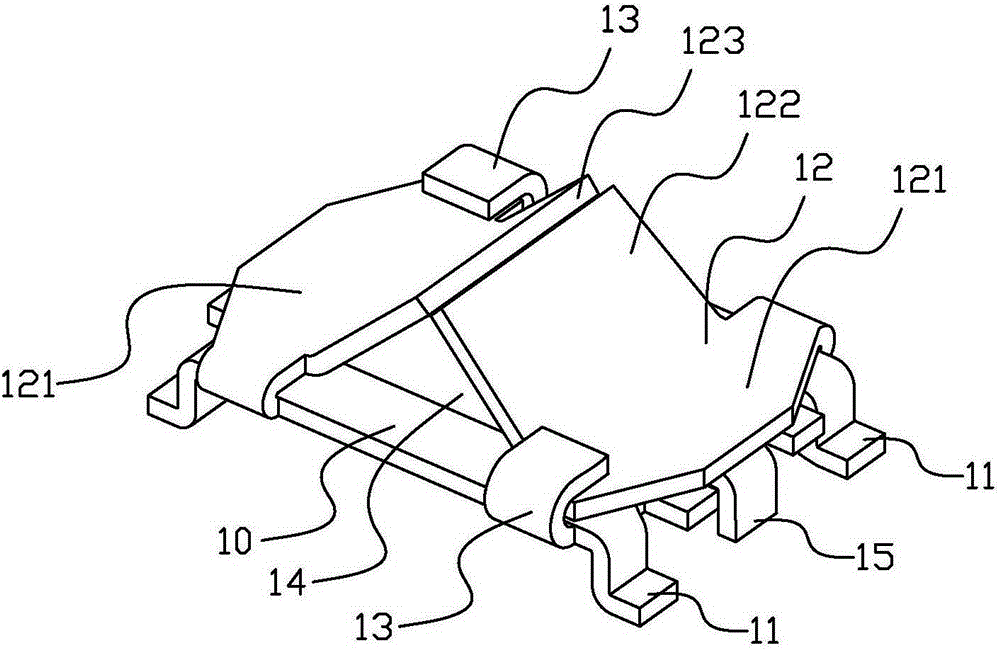

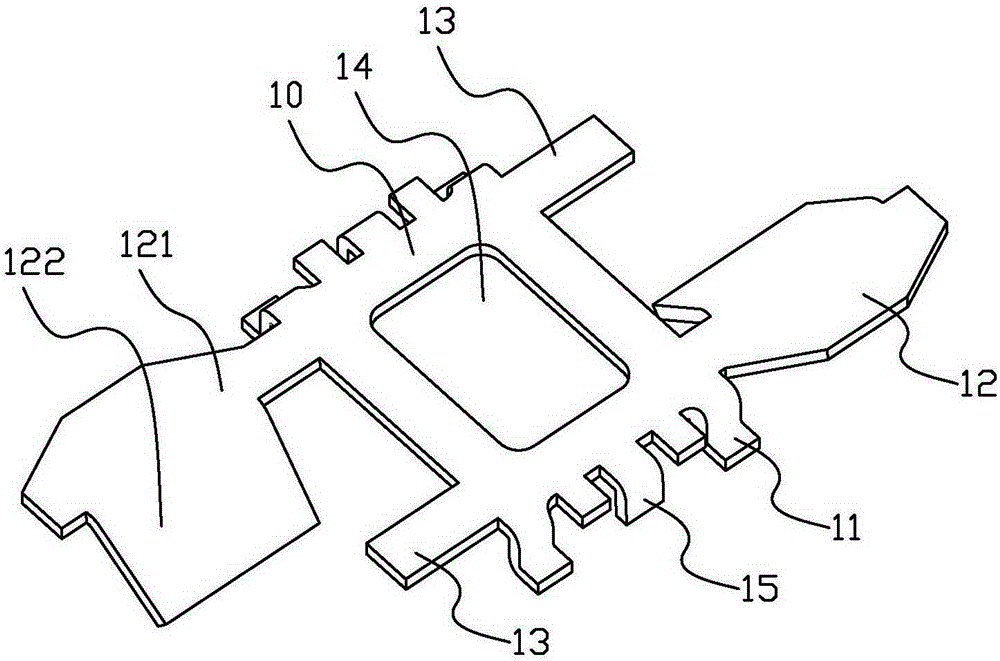

[0016] figure 1 It is a perspective view of the electrical connector of the first embodiment of the present invention. The electrical connector is used to realize the electrical connection between the light source board of the LED lamp and the drive board, and it includes a connecting board 10, which is connected with conductive pins 11, and the electrical connector is fixed on the The light source board is electrically connected with the light source board.

[0017] Please refer to Figure 1 to Figure 3 , in this embodiment, including four conductive pins 11, these conductive pins 11 are arranged around the connecting board 10, and these conductive pins 11 are bent downward from the side of the connecting board 10 to form a "Z" shape structure .

[0018] In addition, it also includes two electrical connecting pieces 12, each electrical connecting piece 12 includes a connecting portion 121 and an ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com