Thread self-locking combined anchor bolt

A combined and threaded technology, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of anchor bolt safety influence, weak fit, and anchor bolt lock not tight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

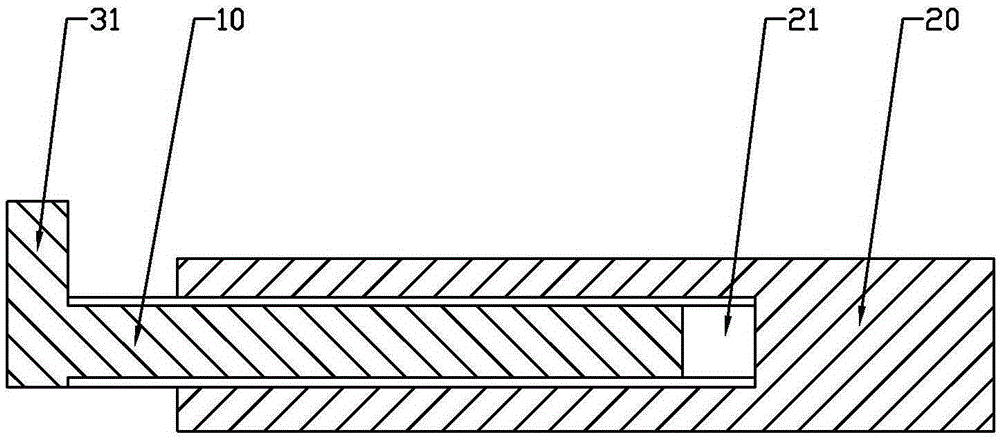

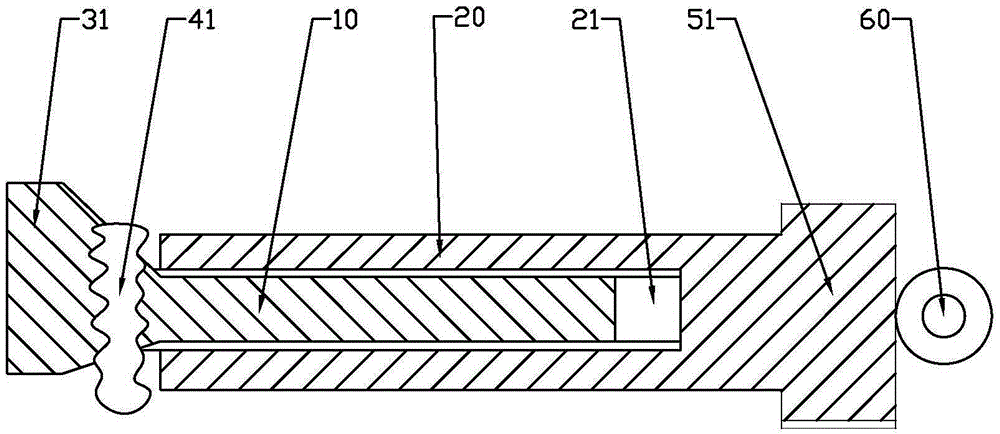

[0035] First embodiment (the inner end of the inner rod 10 is provided with an eccentric countersunk 31):

[0036] Such as figure 1 As shown, a threaded self-locking combined anchor bolt of this embodiment includes an inner rod 10 and an outer rod 20, the body of the inner rod 10 is provided with an external thread segment, and the inner end of the inner rod 10 is provided with Countersunk head, the rod body of the outer rod 20 is provided with a threaded inner hole 21, and the threaded inner hole 21 is provided with an inner threaded section matching the outer threaded section of the inner rod 10, and the outer end of the outer rod 20 is provided with The screw part for screw operation, in this embodiment, the countersunk head is an eccentric countersunk head 31, and the eccentric part 31 of the eccentric countersunk head 31 protrudes out of the outer rod 20, and is set in the anchor hole to be anchored in line with the The eccentric countersunk 31 matches the radial slot, a...

no. 6 example

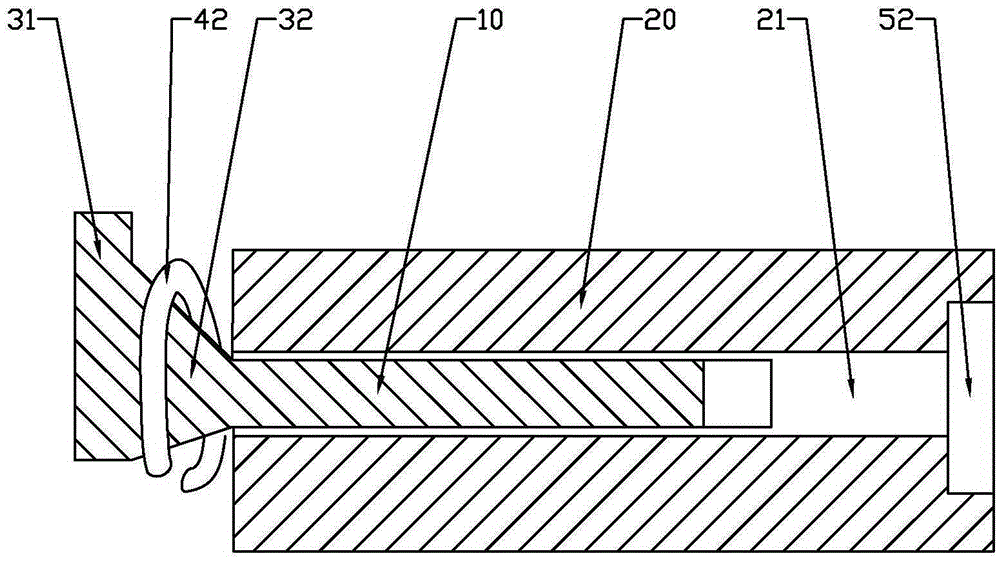

[0046] The sixth embodiment (the inner end of the outer rod 20 is provided with an integrally formed expansion sleeve 43):

[0047] Such as Figure 6 As shown, the difference from the fifth embodiment is that in this embodiment, the expansion sleeve 43 is integrally formed on the inner end of the outer rod 20, and an inner end is provided on the outer end of the outer rod 20. Concave screw port 52, by operating the screw port, the outer rod 20 is threadedly connected with the inner rod 10 and matched with the countersunk head to expand the expansion part and insert it into the anchor hole to be anchored for locking . When the outer rod 20 is screwed inward and squeezes the countersunk head of the inner rod 10, the expansion strip or the expansion sheet expands outward and embeds into the inner wall of the anchor hole to be anchored, thereby realizing the anchoring effect.

[0048] In each of the above-mentioned embodiments, the eccentric countersunk 31 can be provided separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com