Automatic adjustment and deformation device of steel face dam

A technology of automatic adjustment and deformation device, used in dams, barrages, gravity dams, etc., can solve the problems of uneven local force, low efficiency, poor effect, etc., and achieve the effect of prolonging the life of the dam body and adjusting the method quickly and effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

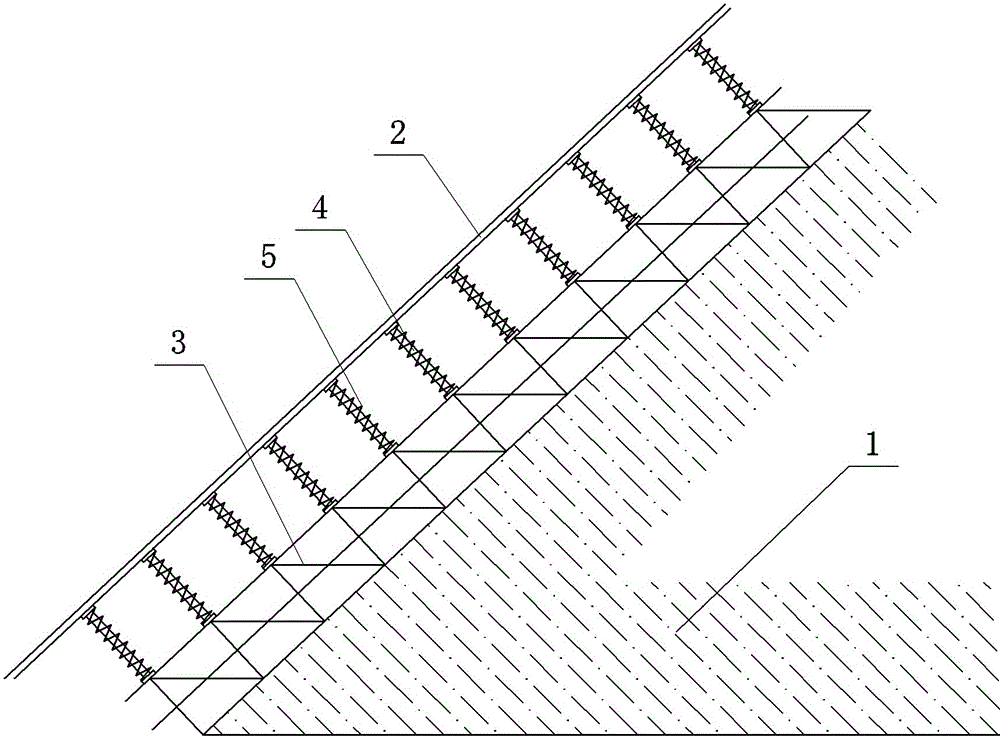

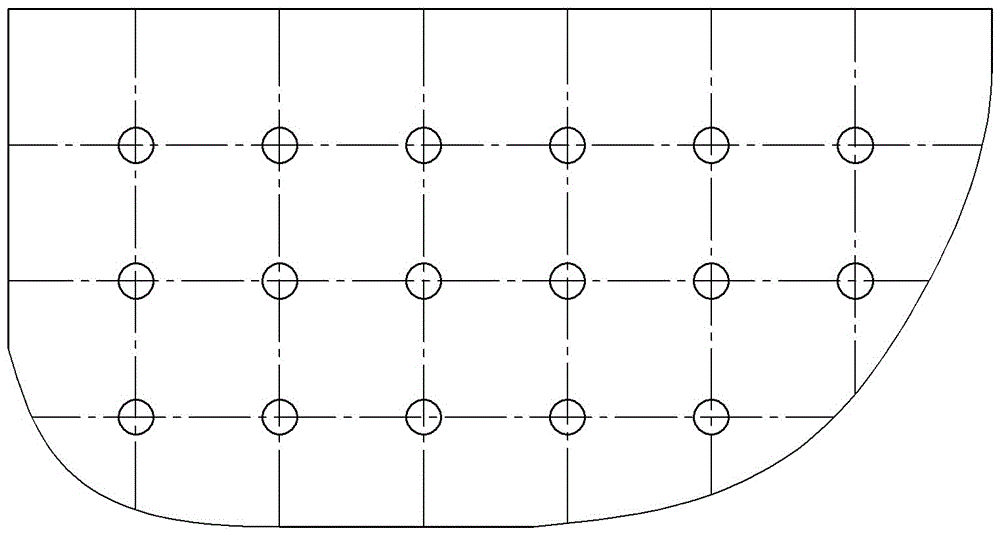

[0016] Example 1: Automatic adjustment and deformation device for steel face dam see figure 1 with figure 2 , a steel truss 3 is set between the dam body 1 and the steel panel 2, and a plurality of deformation adjustments with thrust function are evenly distributed and connected between each fulcrum of the steel truss 3 (where the steel bars meet) and the inner wall of the steel panel 2 device 4. An anchor rod is connected between the steel truss 3 and the dam body 1 .

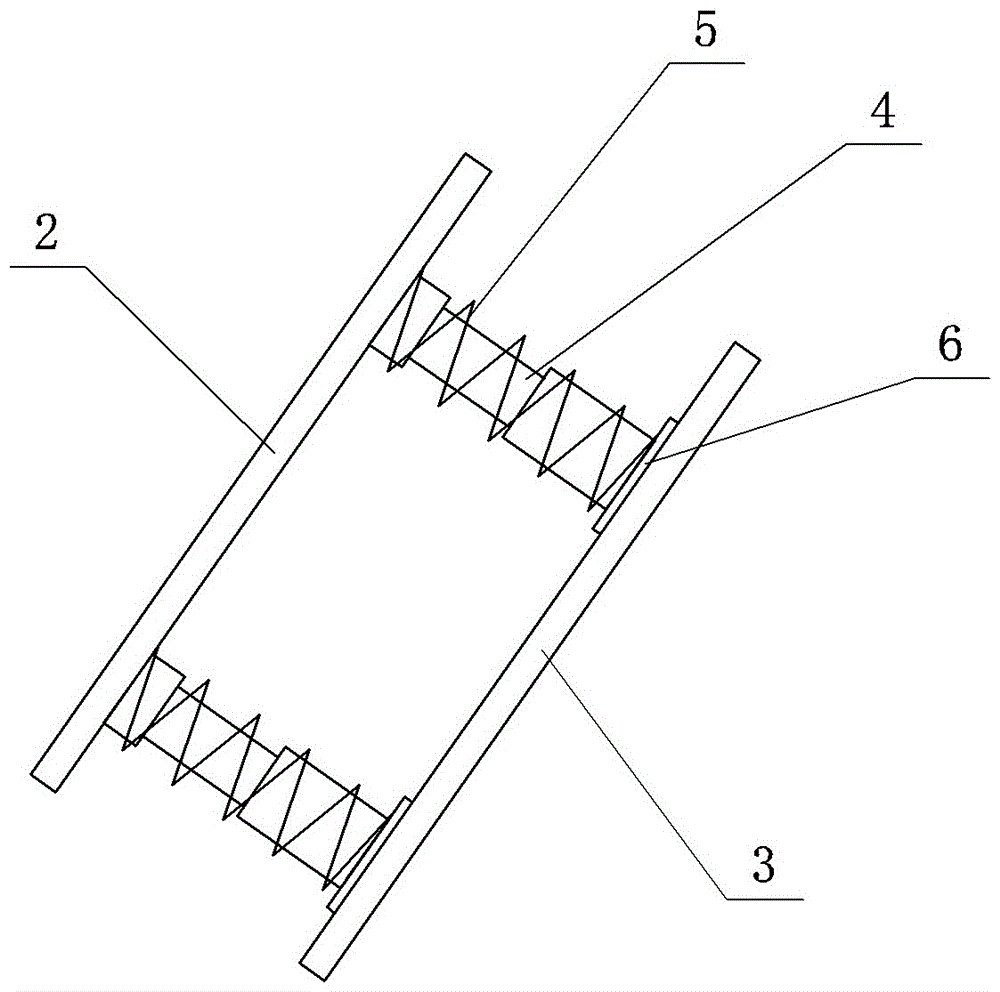

[0017] see image 3 , the deformation regulating device 4 is an oil pressure jack, the deformation regulating device 4 outside is covered with a spring 5, and one or both ends of the spring 5 are equipped with a pressure sensor 6, and the thrust increase or decrease of the deformation regulating device 4 is controlled by judging that the pressure of the spring 5 increases. It can quickly solve the local deformation problem of the steel face dam. Through the information feedback of the pressure spring 5 and...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, a control system is provided, each pressure sensor 6 is connected to the signal input end of the control system, and the output end of the control system drives each corresponding deformation adjustment device 4 . By setting the control system, the pressure sensor 6 can be automatically detected to determine the pressure situation at any position, and the corresponding deformation adjustment device 4 can be adjusted according to the local pressure change, so as to realize the purpose of automatic adjustment.

Embodiment 3

[0019] Embodiment 3: On the basis of Embodiment 1, the deformation adjustment device 4 is changed into an adjustable bolt, and nuts are arranged on both sides of the adjustable bolt. The thread directions of the two nuts are opposite, and the two nuts are respectively welded to the steel panel 2 and the steel structure. On the fulcrum of truss 3. The middle adjustment socket of the adjustable bolt can be easily adjusted by inserting the lever.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com