Guide rail straightening device

A guide rail and straightening technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive local elastic-plastic deformation of guide rails, poor straightening effect, and guide rails that cannot be straightened, and achieve the straightening effect. Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments illustrate the guide rail straightening device of the present invention in detail with reference to the accompanying drawings.

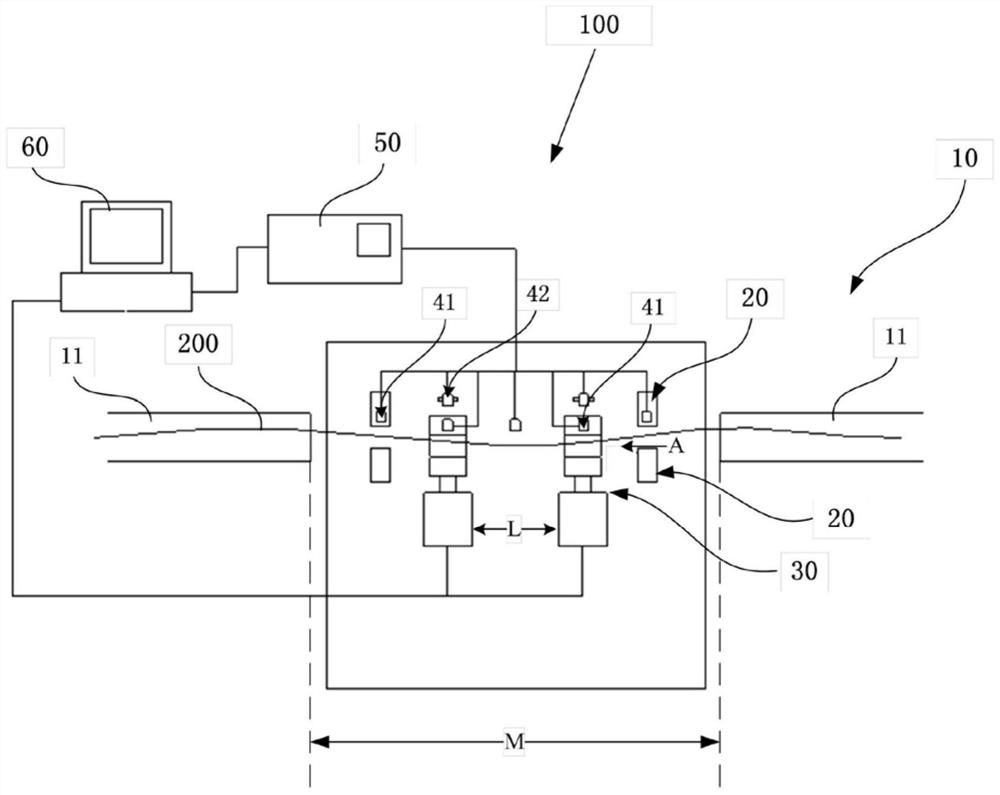

[0015] figure 1 It is a structural schematic diagram of the guide rail straightening device in the embodiment of the present invention.

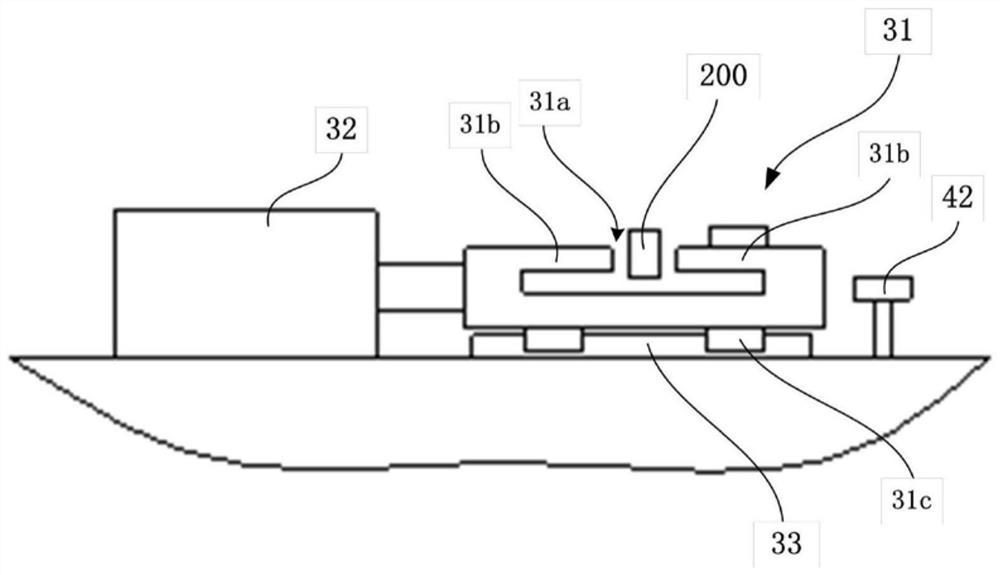

[0016] like figure 1 As shown, in this embodiment, the guide rail straightening device 100 is used to straighten the guide rail 200 , including: a support part 10 , four contact parts 20 , two pressure loading parts 30 and a control part 40 .

[0017] The supporting part 10 includes two supporting platforms 11 , and the two supporting platforms 11 are arranged opposite to each other with a predetermined distance M for supporting the guide rail 200 .

[0018] In this embodiment, the structures of the four abutting parts 20 are completely the same, and onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com