Persea americana oil enzymolysis extraction method

An extraction method and avocado oil technology, applied in the field of bioengineering, can solve the problems of high cost, long cycle, poor oil quality, etc., and achieve the effects of improving oil yield, significant effect, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

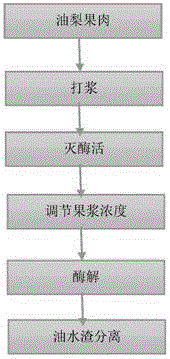

Method used

Image

Examples

Embodiment 1

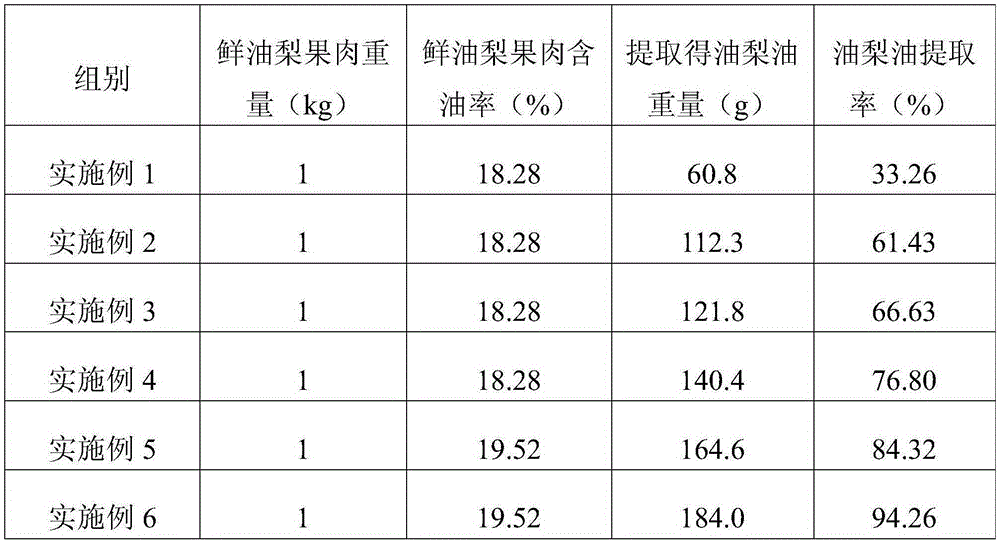

[0027] Put 1 kg of fresh avocado pulp (the oil content of the pulp is 18.28%) into a beater, add water and beat, and the resulting pulp passes through an 80-mesh sieve; heat the pulp to 80°C for 5 minutes to inactivate the enzyme activity; The concentration of the live pulp is adjusted so that the ratio of fresh pulp to water is 1:4, and pectinase is added to account for 1.5‰ of the mass of fresh pulp, and the enzymatic hydrolysis is carried out at 45°C for 12 hours, and 60.8g of oil is separated, and then the avocado oil is counted The extraction rate (see Table 1 for details).

Embodiment 2

[0029] Put 1 kg of fresh avocado pulp (the oil content of the pulp is 18.28%) into a beater, add water and beat, and the resulting pulp passes through an 80-mesh sieve; heat the pulp to 80°C for 5 minutes to inactivate the enzyme activity; The concentration of the live pulp is adjusted so that the ratio of fresh pulp to water is 1:4, cellulase is added to account for 3.0‰ of the mass of fresh pulp, and the enzymatic hydrolysis is carried out at 55°C for 12 hours, and 112.3g of oil is separated, and then the avocado oil is counted The extraction rate (see Table 1 for details).

Embodiment 3

[0031] Put 1 kg of fresh avocado pulp (the oil content of the pulp is 18.28%) into a beater, add water and beat, and the resulting pulp passes through an 80-mesh sieve; heat the pulp to 80°C for 5 minutes to inactivate the enzyme activity; The concentration of live pulp is adjusted to the ratio of fresh pulp and water of 1:4, adding dextranase to account for 1.5‰ of the mass of fresh pulp, and heat preservation at 55°C for enzymolysis for 12 hours, 121.8g of oil is separated, and then the oil is counted The extraction rate of pear oil (see Table 1 for details).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com