Method and device for removing impurity sulfur dichloride in thionyl chloride

A technology of thionyl chloride and sulfur dichloride, which is applied in the direction of sulfur and halogen compounds, can solve problems such as pipeline blockage, packing blockage in the distillation tower pipeline tower, and gas condensation, etc., to achieve convenient replenishment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0031] The following devices are used in this embodiment 1-3:

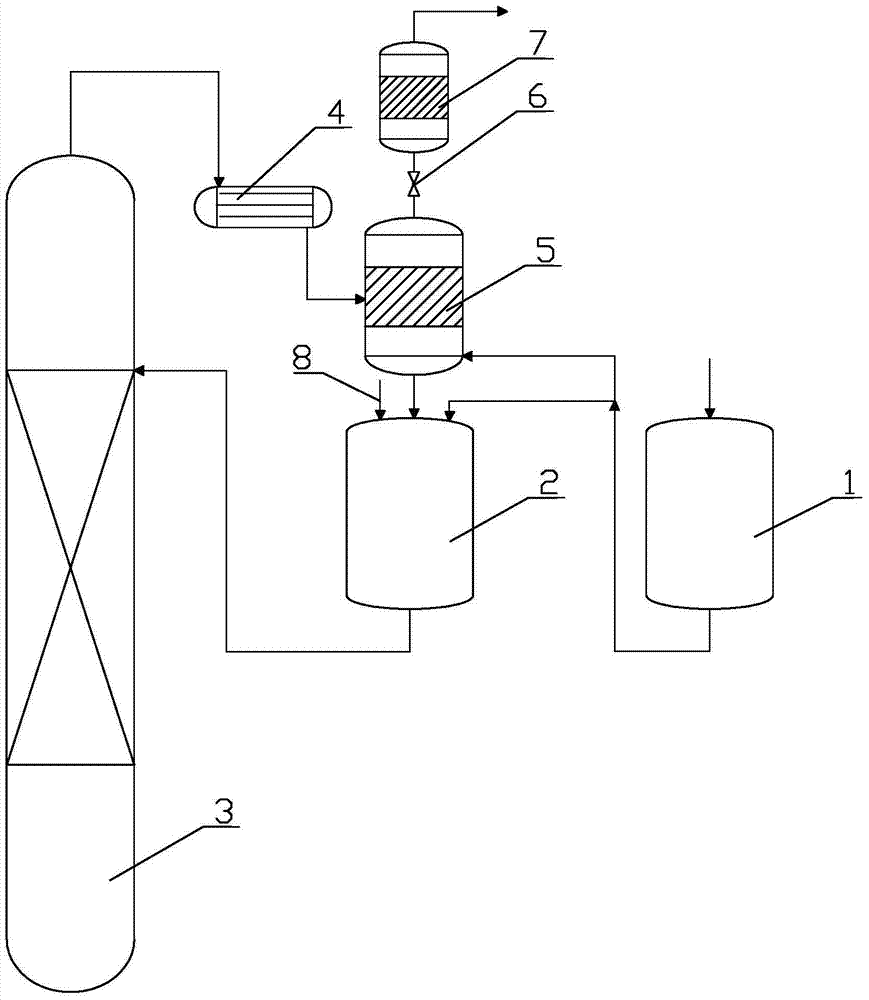

[0032] Such as figure 1 As shown, the device for removing sulfur dichloride impurities in thionyl chloride includes crude product receiving tank 1, crude product receiving tank 1 through pipeline and sulfur distribution tank 2, rectification tower 3, heater 4, oversulfur The tanks 5 are connected in sequence, and a liquid sulfur line 8 is provided on the top of the sulfur distribution tank 2.

[0033] The top of the oversulfur tank 5 is connected with a sulfur feed tank 7 through a pipeline, and a spherical valve 6 is provided on the pipeline between the oversulfur tank 5 and the sulfur feed tank 7.

[0034] The bottom of the supersulfur tank 5 is connected to the crude product receiving tank 1 and the sulfur distributing tank 2 respectively.

Embodiment 1

[0036] The crude product of thionyl chloride is pumped from the crude product receiving tank 1 into the sulfur distributing tank 2, and then liquid sulfur is added to the sulfur distributing tank 2 through the liquid sulfur line 8, so that sulfur dichloride and sulfur are reacted and converted into sulfur monochloride. The sulfur dichloride in the crude thionyl chloride after sulfur was measured to be 2.3%, and it was fed into the rectification tower 3 for rectification and separation under the condition of the top pressure of 4kPa. The thionyl chloride separated at the top Sulfur dichloride enters the heater 4, the temperature rises to 85℃, enters from the bottom of the oversulfur tank 5, after passing through the 700mm high sulfur bed, the sulfur dichloride in the product thionyl chloride at the top of the oversulfur tank 5 is measured The content is 0.003%, which meets the requirements of the industry standard for the color of superior product 1#.

[0037] Wherein, the diamete...

Embodiment 2

[0039] The crude product of thionyl chloride is pumped from the crude product receiving tank 1 into the sulfur distributing tank 2, and then liquid sulfur is added to the sulfur distributing tank 2 through the liquid sulfur line 8, so that sulfur dichloride reacts with sulfur to convert to sulfur monochloride. The sulfur dichloride content in the crude thionyl chloride after sulfur is measured to be 2.0%. It is fed into the rectification tower 3 for rectification separation under the condition of the top pressure of 7kPa. The thionyl chloride separated at the top Sulfur dichloride enters the heater 4, the temperature rises to 88°C, enters from the bottom of the oversulfur tank 5, after passing through the 790mm high sulfur bed, the sulfur dichloride in the product thionyl chloride at the top of the oversulfur tank 5 is measured The content of sulfur is 0.0025%. After 2 hours of continuous operation, the height of the sulfur bed becomes 650mm, and the content of sulfur dichloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com