Waterborne propulsion resistance reduction device for all-terrain vehicle

A resistance-reducing, all-terrain technology, applied in motor vehicles, amphibious vehicles, transportation and packaging, etc., can solve the problems of large water propulsion resistance of amphibious special vehicles, and achieve smooth water propulsion, small footprint, and easy modification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

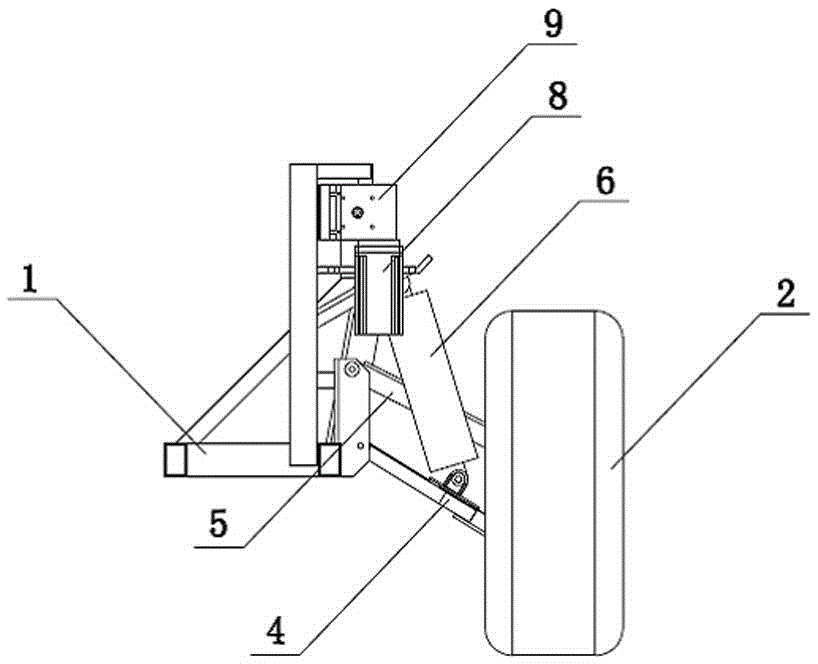

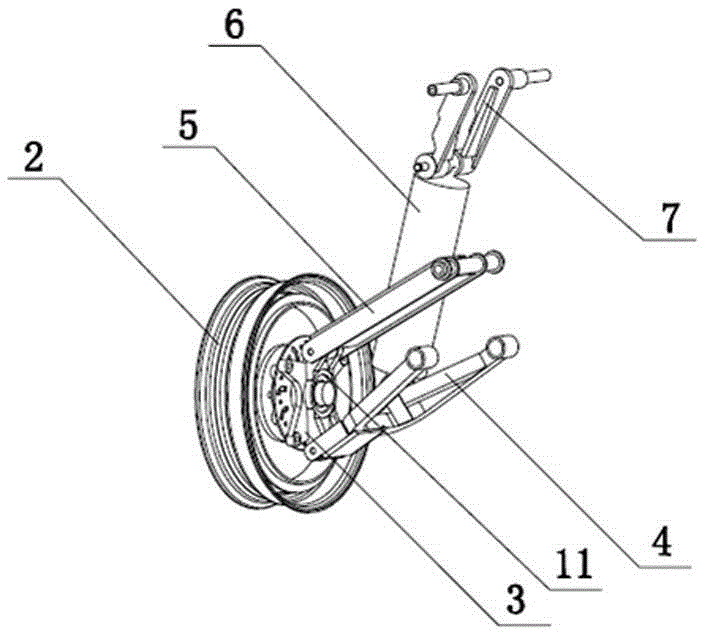

[0025] Example: such as figure 1 , figure 2 with image 3 As shown, a propulsion and drag reduction device for an all-terrain vehicle on water includes a vehicle frame 1 and a tire 2, a thrust bearing 11 is arranged in the steel ring shaft hole of the tire 2, a support seat 3 is arranged on the thrust bearing 11, and a support seat 3 is arranged on the thrust bearing 11. A pair of upper swing arm 5 and lower swing arm 4 arranged in parallel are hinged up and down on the longitudinal end face, and the other free ends of upper swing arm 5 and lower swing arm 4 are hinged to the vehicle frame 1. The hinged positions of the support seat 3 are respectively located on the upper and lower sides of the central position where the thrust bearing 11 is located, and the distance from the two hinged positions to the central position is equidistant.

[0026] A shock-absorbing rod 6 is hinged on the lower swing arm 4, and the hinged position of the lower swing arm 4 and the shock-absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com