Double-station drilling tooling with soft start circuit

A technology of slow start circuit and drilling tooling, which is applied in the direction of driving device, drilling/drilling equipment, manufacturing tools, etc. It can solve the problems of low work efficiency, cumbersome process, and unresponsive workers, so as to achieve high work efficiency, The process is simple and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

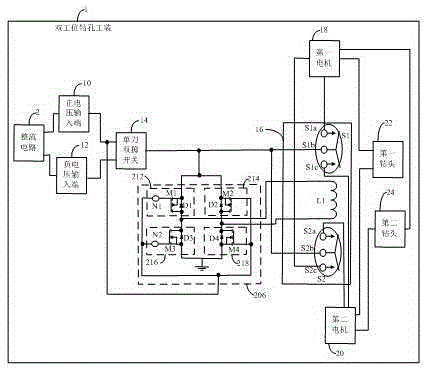

[0019] figure 1 It is a structural schematic diagram of an embodiment of the double-station drilling tool 1 of the present invention. In the figure, 1 is a double-station drilling tool, 2 is a rectifier circuit, 10 is a positive voltage input terminal, 12 is a negative voltage input terminal, 14 is a single-pole double-throw switch, 16 is a selection unit, 18 is a first motor, 20 22 is the first drill bit, 24 is the second drill bit, 206 is the control unit, 212 is the first control circuit, 214 is the second control circuit, 216 is the third control circuit, 218 is the fourth control circuit, D1-D4 are the first to fourth diodes, M1-M4 are the first to fourth field effect transistors, N1-N2 are the first to second inverters, L1 is the coil, S1-S2 are the first to the second inverters The second contact group type switch.

[0020] see figure 1 , is a structural schematic diagram of an embodiment of the double-station drilling tool 1 of the present invention. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com