Composite dust collecting plate for electrostatic dust removal

A technology of electrostatic dust removal and dust collection board, which is applied in electrostatic separation, electrode structure, chemical instruments and methods, etc., can solve the problems of low dust storage capacity, low capture of tiny dust, and high frequency of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

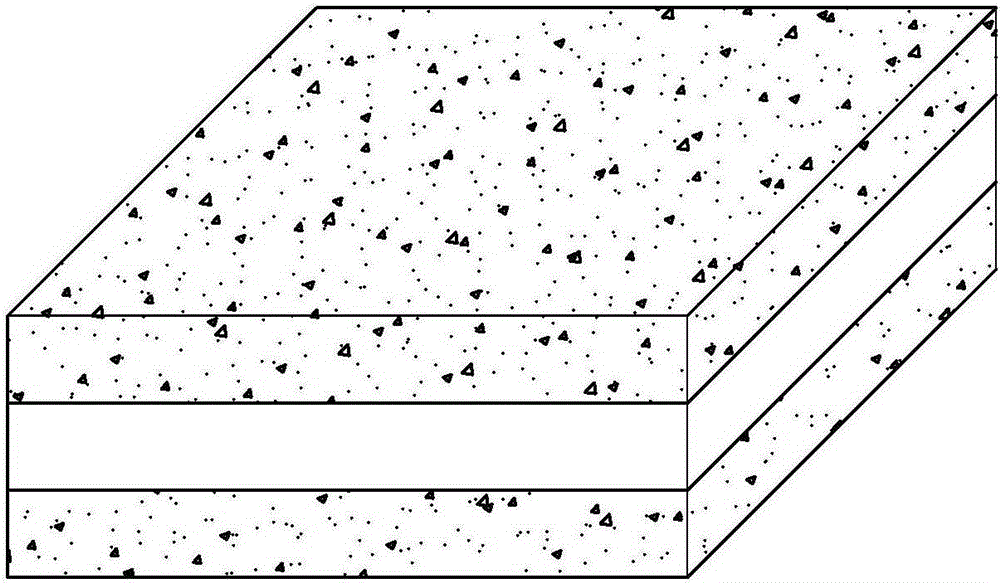

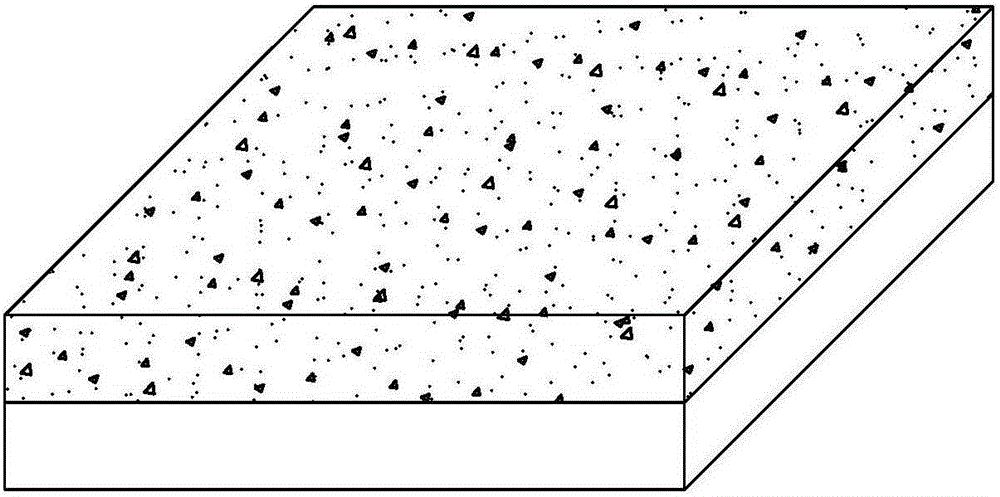

[0017] Such as figure 1 and figure 2 As shown, the composite dust-collecting plate for electrostatic dust removal of the present invention includes a dust-collecting electrode 1 made of conductive material, and the dust-collecting electrode 1 is preferably made of metal materials such as stainless steel, aluminum, copper, etc., and the dust-collecting electrode 1 The surface is provided with a dust-absorbing layer 2 made of a filamentous or porous material, and the electrical conductivity of the filamentous or porous material constituting the dust-absorbing layer 2 is 1×10 -8 S / m—1×10 -5 S / cm. It is particularly emphasized that the electrical conductivity of the filamentous or porous material constituting the dust-absorbing layer 2 can only be 1×10 -8 S / m—1×10 -5 S / cm, the reason is that if the dust-absorbing layer 2 is made of metal wire, so that the dust-absorbing layer 2 can be completely conductive as a conductor, then because the electrostatic charge will tend to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com