industrial filter

A filter and industrial technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems of low service life, easy accumulation of filter bags, large volume, etc. The effect of even air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

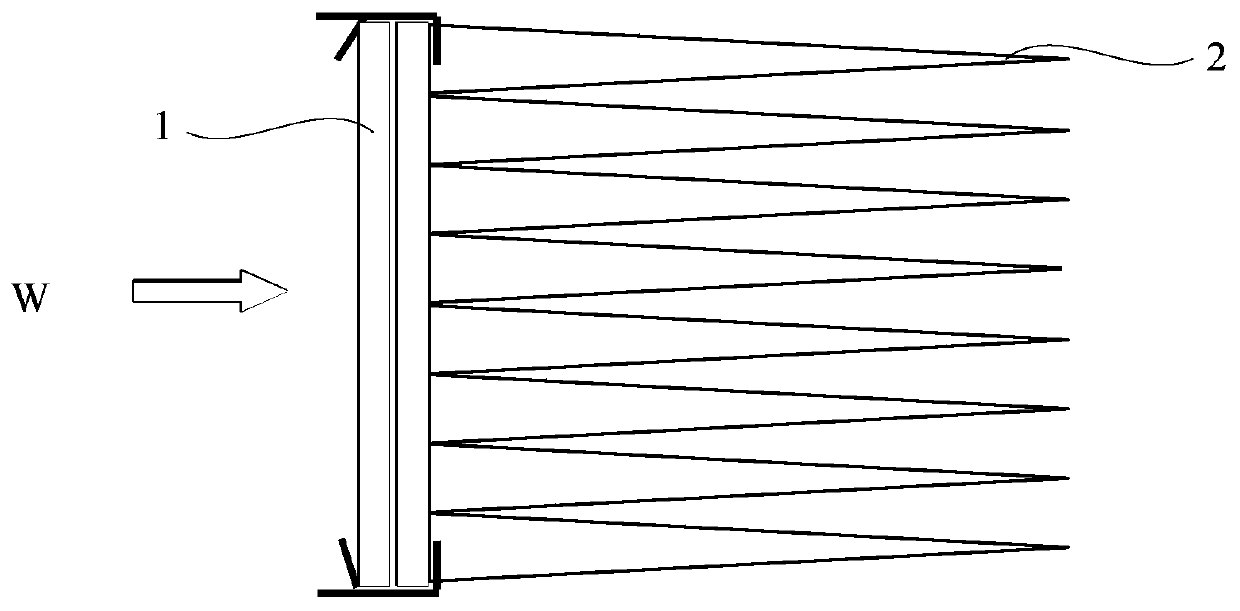

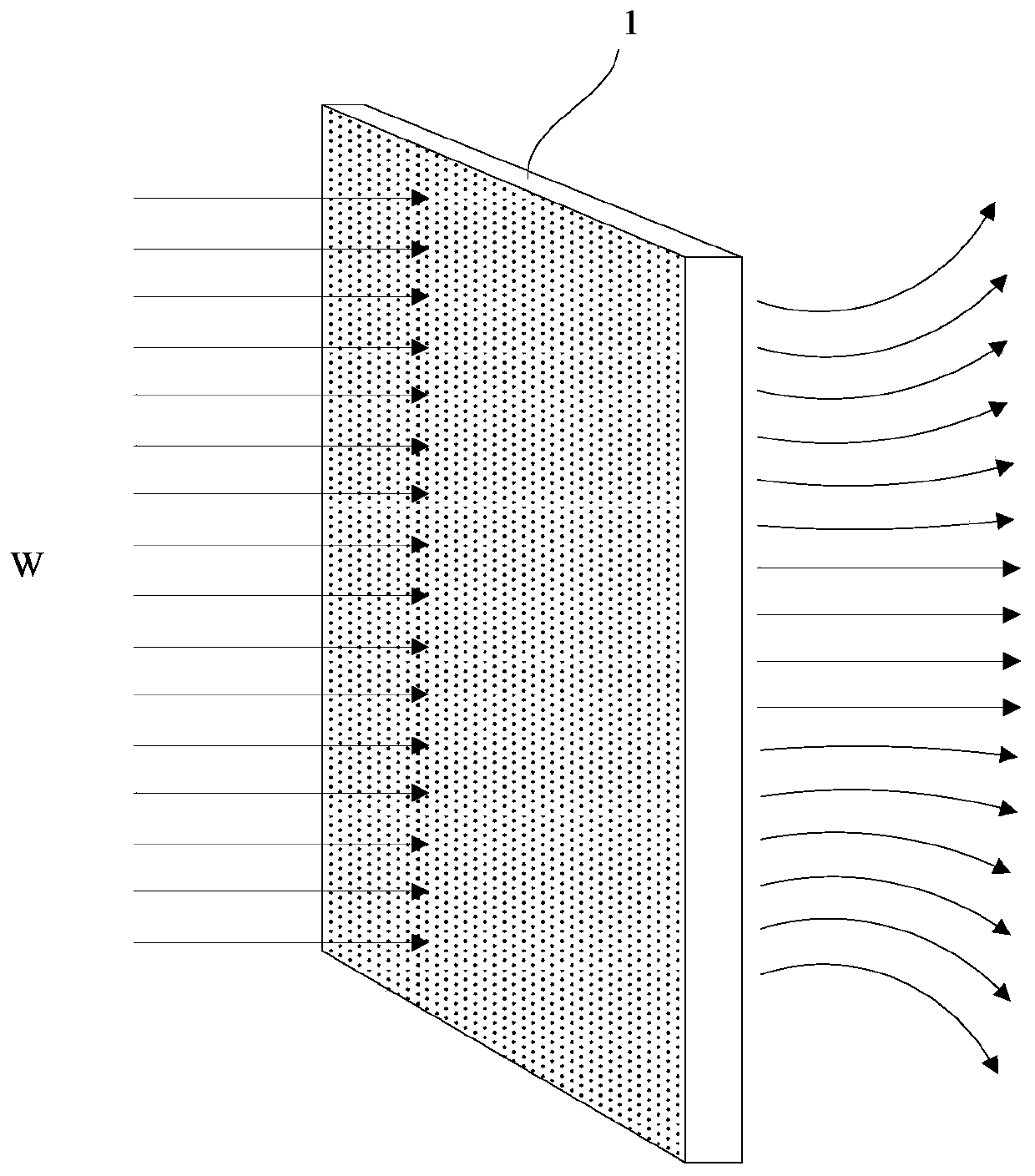

[0041] An embodiment of the present invention provides an industrial filter, referring to Figure 4-5 , including a first filter 100, the first filter 100 is a bag filter, including a first support frame 110 ( Figure 4 not shown in the Figure 5 ) and the first filter bag 120 arranged on the first support frame 110, the first support frame 110 is used to support the first filter bag 120, and the first filter bag 120 has a first opening 121.

[0042] Wherein, the quantity of the first filter bag 120 can be set according to the size of the air vent and filtering requirements, Figure 4 5 first filter bags 120 arranged side by side are exemplarily shown, each first filter bag 120 has a first opening 121, there is a gap between adjacent first filter bags 120 and close to the first opening One side of 121 is sealed and connected. In other embodiments, the number of first filter bags can also be other values.

[0043] Such as Figure 5 , the first support frame 110 is a skelet...

Embodiment 2

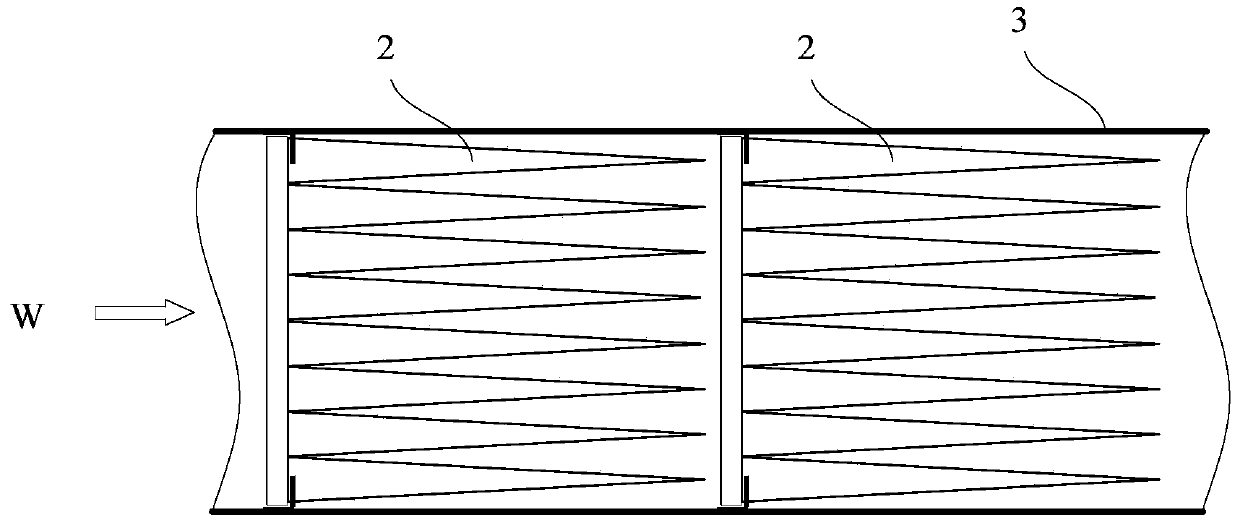

[0053] The difference between this embodiment and Embodiment 1 is that, referring to Figure 8-9 , the industrial filter of this embodiment also includes a second filter 200 located downstream of the first filter 100 along the air intake direction, that is, the second filter 200 is located on the side of the first filter 100 with the first opening 121, And it is sealed and connected with the first filter 100 through the connecting frame 310 . Specifically, the connection frame 310 includes a first frame 311 connected to a filter 100 and a second frame 312 connected to the second filter 200, the first frame 311 surrounds the air outlet of the first filter 100, and the second frame 312 Surrounds the air inlet of the second filter 200 . The first frame 311 and the second frame 312 are sealed and connected.

[0054] In this embodiment, the first frame 311 and the second frame 312 are connected by buckles 320, and seals 330 are provided between the first frame 311 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com