Pit toilet with function of converting excrement into sterile and odorless organic fertilizers

An organic fertilizer and excrement technology, applied in the field of environmental sanitation facilities, can solve the problems of no sterilization measures, no deodorization measures, and increase the difficulty of decomposing, so as to reduce the burden on farmers, improve the organic matter of farmland, and realize the effect of a virtuous circle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

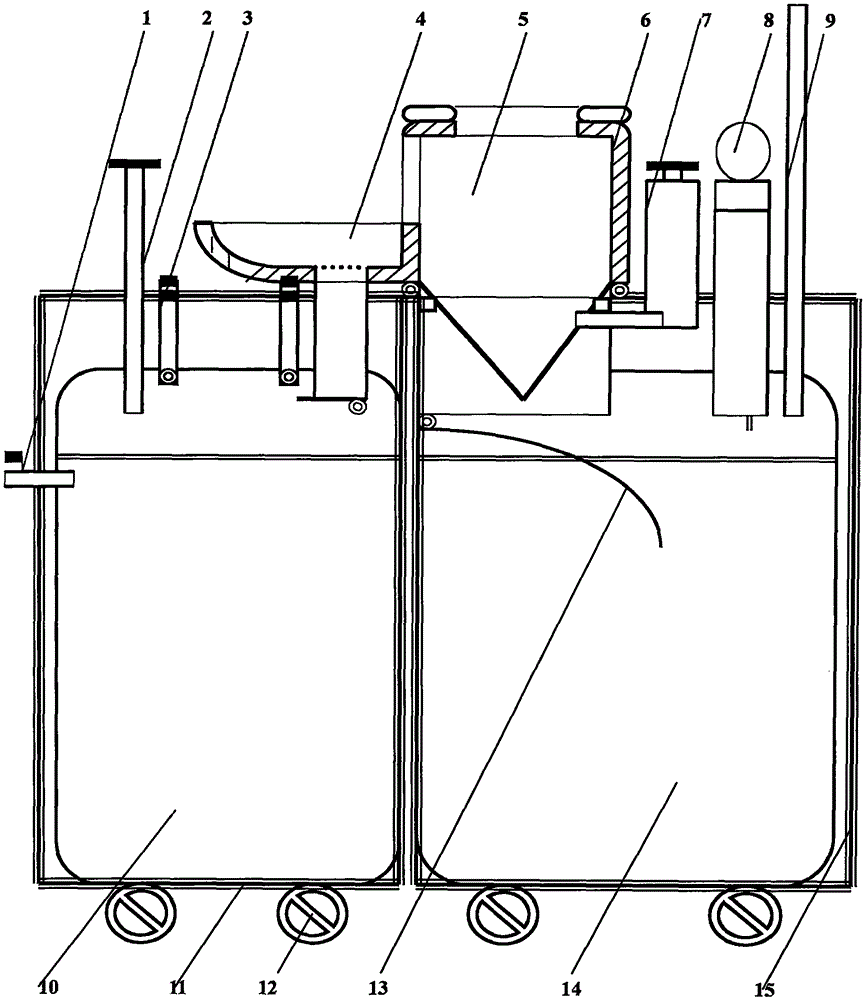

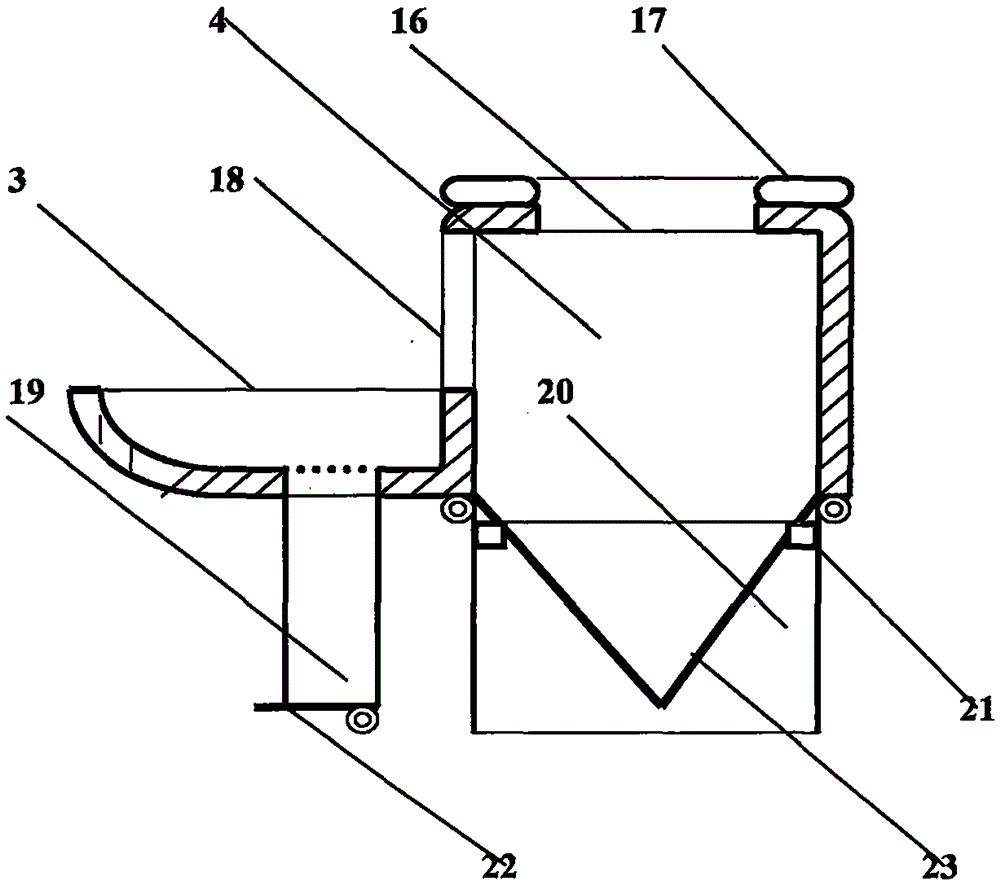

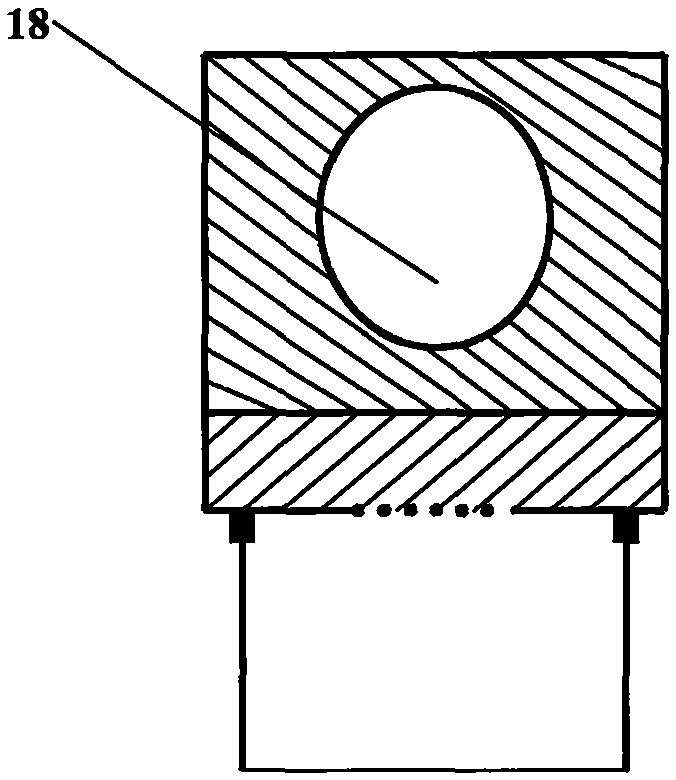

[0027] Such as figure 1 , figure 2 , image 3 As shown, the source separation toilet 6 is composed of a urinal 4 and a toilet 5 . The bottom of the urinal 4 is provided with a urinal closed chamber 19, and an automatic valve plate 22 of the urinal cavity is installed at the lower end of the urinal closed chamber 19. Install the allantoic discharge valve 1 and install the allantoic pressurizer 2. The toilet seat 16 of the closet 5 is provided with a toilet inflatable pad 17, and a toilet urinal 18 is arranged on the front and lower part of the toilet 5, and the toilet urinal 18 communicates with the urinal 4, and the bottom of the toilet 5 is provided with Stool closed cavity 20, stool cavity automatic valve plate 23 is installed at the lower end of stool closed cavity 20, and counterweight 21 is installed on the stool cavity automatic valve plate 23, and stool closed cavity 20 is connected with ight soil processing bag 14, and in the stool processing bag The top of 14 is ...

Embodiment 2

[0029] On the basis of Example 1, as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, a reactant 25 is placed in the reactant adder 8, a pressurized bag 24 is provided at the top of the reactant adder 8, and a reactant outlet 26 is provided at the lower end. The inflatable toilet seat cushion 17 is provided with a valve core 27 through which gas 28 is filled into the toilet seat inflatable cushion 17 .

Embodiment 3

[0031] On the basis of Example 1, as figure 1 As shown, the urine treatment bag 10 is connected to the allantoic holder 11 with the lanyard 3, and the feces treatment bag 14 is connected to the fecal bag holder 15 with the lanyard 3. The bottom installation pulley 12. The source separation toilet 6 is installed above the urine disposal bag 10 and the excrement disposal bag 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com