Preservative composition and use thereof

A technology of preservatives and compositions, applied in the field of food additives, can solve the problems of affecting food preservatives and quality, failing to achieve antiseptic effect, and not having inhibition, so as to inhibit the biofilm of food-borne pathogenic bacteria and inhibit food Pathogen-derived biofilm formation, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] 2.1 Preparation of bacterial suspension

[0051] After activation, Bacillus cereus was inoculated in sterile broth medium and cultured at 37 °C for 12 h until the number of viable bacteria reached 10. 8 CFU / mL, spare.

[0052] 2.2 Preparation of biofilm

[0053] (1) Cleaning of the carrier sheet: Rinse the carrier sheet with natural water, put it in acetone for 15 min (ultrasonic frequency 40kHz, ultrasonic power 250 W) to remove surface oil; then, soak it in 75% ethanol for 30 min, then cleaned with detergent, finally rinsed with distilled water, dried and sterilized for later use.

[0054] (2) Cultivation of biofilm: add carrier sheet and 10 mL broth medium into the test tube, after sterilization, insert 1% of the above bacterial suspension (10 8 CFU / mL), cultured at 37 ℃.

[0055] 2.3 Determination of the number of viable bacteria in the biofilm

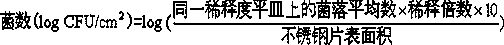

[0056] The number of biofilm bacteria was calculated according to the following formula:

[0057]

[0058] Ultra...

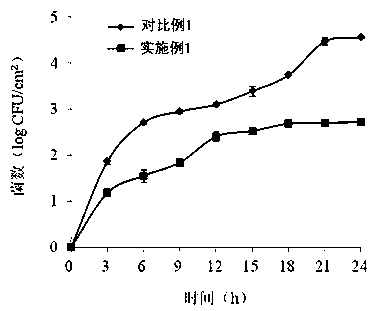

Embodiment 1

[0060] Weigh 0.05g of ethyl p-hydroxybenzoate and 0.05g of disodium ethylenediaminetetraacetic acid respectively, add them to 1000mL of 30% ethanol solution, and after fully dissolving, a preservative with a concentration of 0.1g / L is obtained combination.

Embodiment 2

[0062] Weigh 0.03g of ethyl p-hydroxybenzoate and 0.02g of disodium ethylenediaminetetraacetic acid respectively, add them to 1000mL of 30% ethanol solution, and after fully dissolving, a preservative with a concentration of 0.05g / L is obtained combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com