Solid phase dual-dynamic enzymolysis fermentation technology for feed raw materials

A technology of feed raw materials and fermentation process, which is applied in the field of fermentation to achieve the effects of cost saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

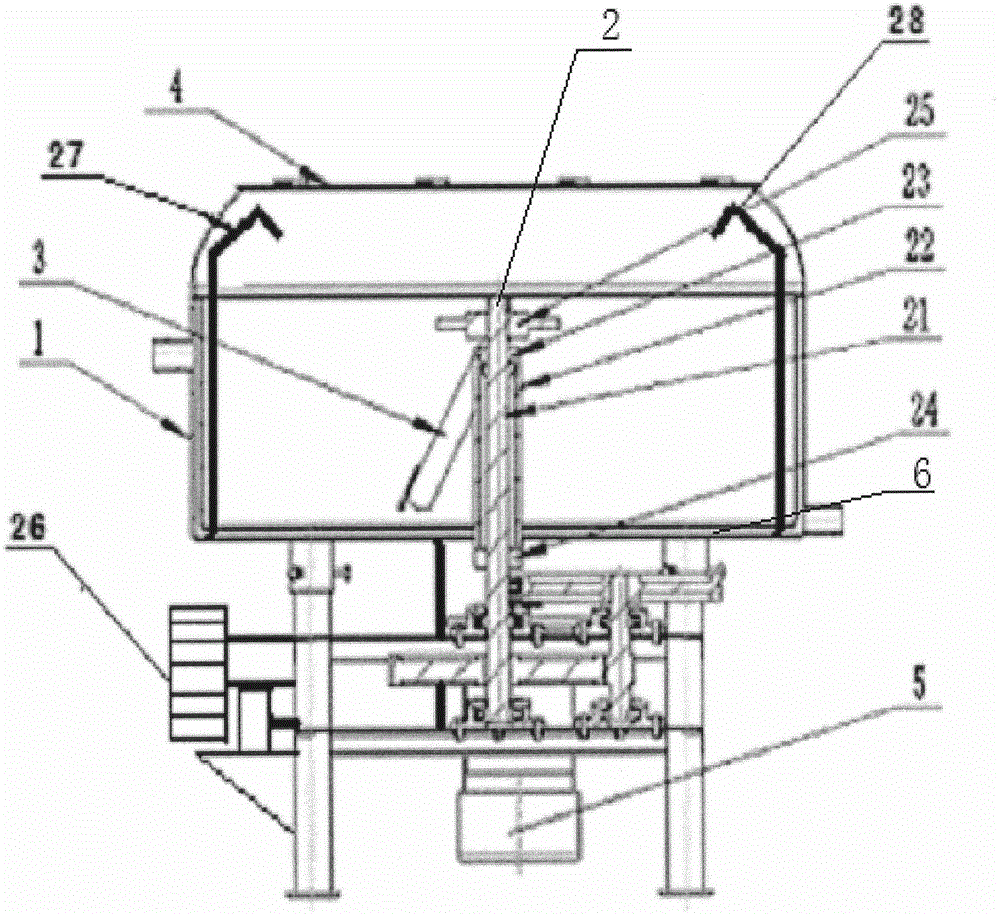

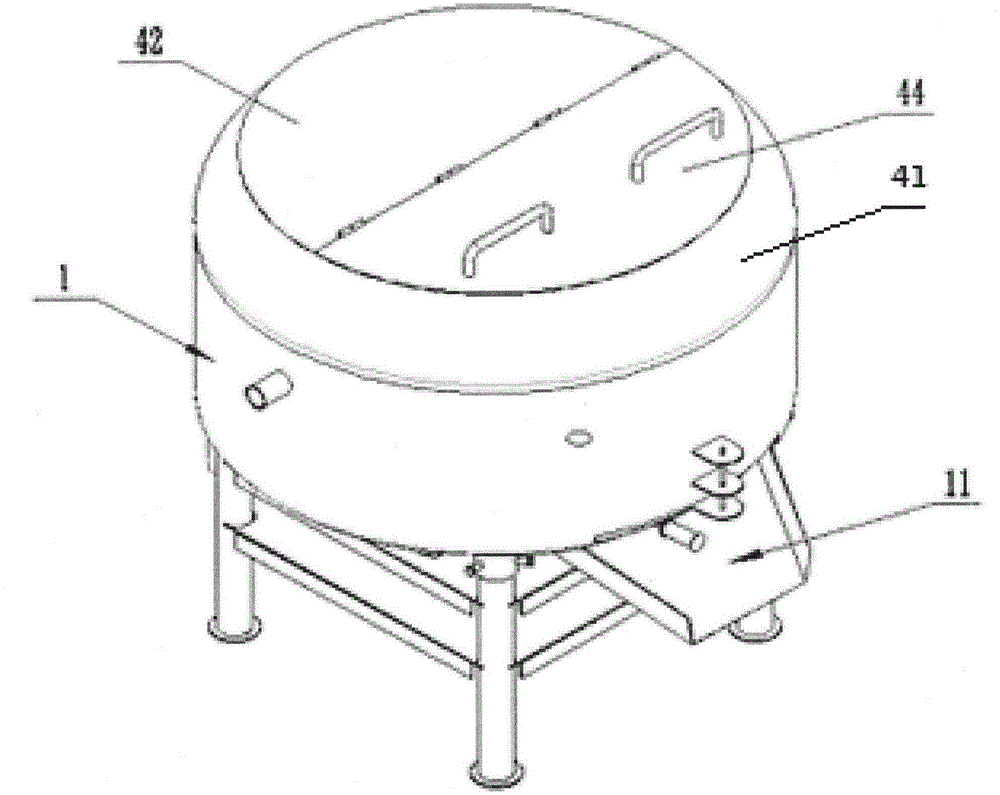

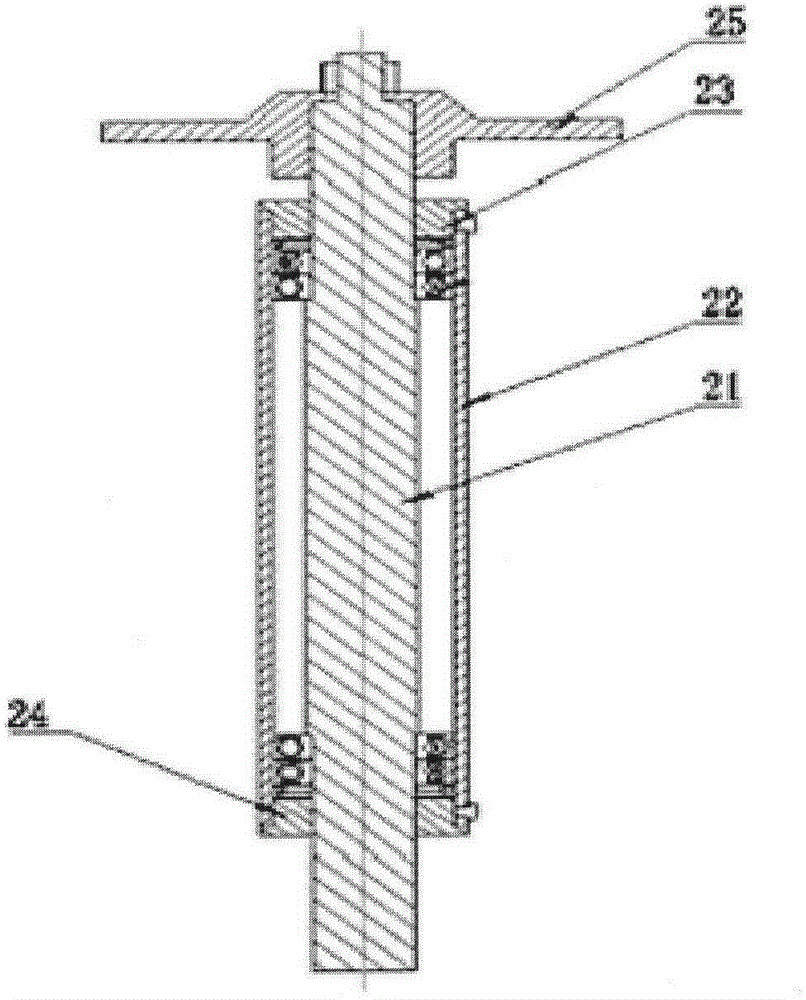

[0032] Such as figure 1 , figure 2 As shown, the solid-phase double-dynamic enzymolysis fermentation device includes a housing 1 and a stirring shaft installed in the housing 1, the stirring shaft is connected to the drive motor 5, and the stirring shaft is provided with a stirring shovel 3, and the housing The upper end of the body 1 is provided with an end cover 4, and the lower end is provided with a bottom plate, which is characterized in that: the stirring shaft is mounted on the bottom plate of the housing 1 through a bearing, such as image 3 , Figure 4 As shown, the stirring shaft includes a central shaft 21, a shaft sleeve 22 that is sleeved on the central shaft 21 through a bearing, and an upper gland 23 and a lower gland 24 are arranged between the two ends of the shaft sleeve 22 and the central shaft 21 , the top of the central shaft 21 is fixedly connected with an upper disc 25, the mixing shovel 3 includes a cylindrical shovel handle, a flat plate-shaped shov...

Embodiment 2

[0036] Farm self-prepared full-price feed: the composition of the full-price feed is 70% corn, 15% soybean meal, 6.4% cassava flour, 5% bran, 1.5% trace elements, 1.5% microorganisms, and 0.6% calcium hydrogen phosphate .

[0037] A. Equipment inspection: turn on the power, check whether the indicator light of the equipment and the water level of the water tank are normal, close the discharge port, turn on the automatic heating, and set the temperature: 37°C for the special bacteria for enzymatic detoxification of feed raw materials;

[0038] B, feed intake: open the warehouse door, open manual stirring, after throwing 100% self-prepared full-price material successively according to the formula and mixing, then drop into 0.1% by weight of feed raw material enzymatic detoxification special bacteria (Enterococcus faecalis: Lactobacillus plantarum : Saccharomyces cerevisiae: Bacillus subtilis: zeolite powder=1: 3: 3: 2: 1), fully stirred evenly;

[0039] C. Adjust the water cont...

Embodiment 3

[0042] Fermented soybean meal:

[0043] A. Equipment inspection: turn on the power, check whether the indicator light of the equipment and the water level of the water tank are normal, close the discharge port, turn on the automatic heating, and set the temperature: 37°C for the special bacteria for enzymatic detoxification of feed raw materials;

[0044] B, feed intake: open the warehouse door, open manual stirring, drop into 70% soybean meal and 30% bran successively according to formula, then drop into 0.1% by weight percentage of feed raw material enzymatic detoxification special bacteria (Enterococcus faecalis: Lactobacillus plantarum: Saccharomyces cerevisiae Yeast: Bacillus subtilis: zeolite powder=1:3:3:2:1), fully stir evenly;

[0045] C. Adjust the water content: add an appropriate amount of water according to the total amount of materials in the tank, stir well, and control the moisture content of the materials at about 40%, that is, hold the materials lightly, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com