Control device and control method for automatically mixing glue

A control device and glue blending technology, which is applied in the program control and electrical program control of the sequence/logic controller, etc., can solve the problems affecting the batching accuracy and glue blending quality, reducing the bonding strength of wood products, and poor working reliability. , to achieve the effect of simple structure, stable glue quality and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

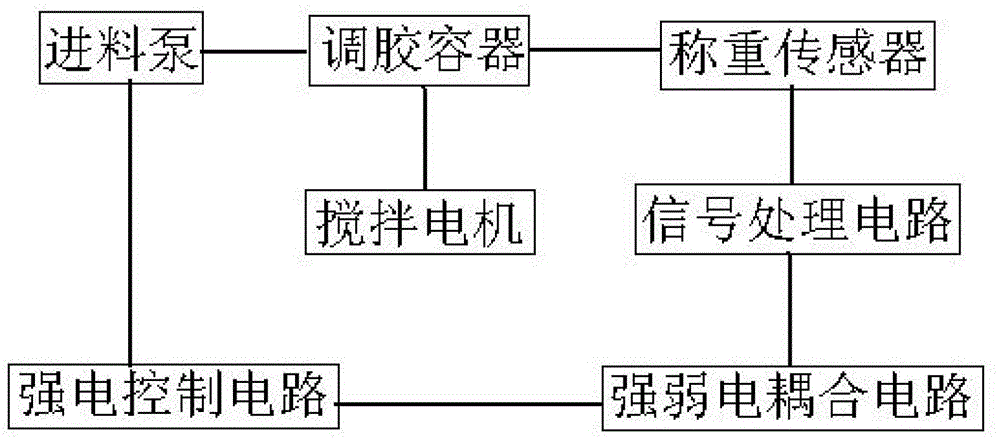

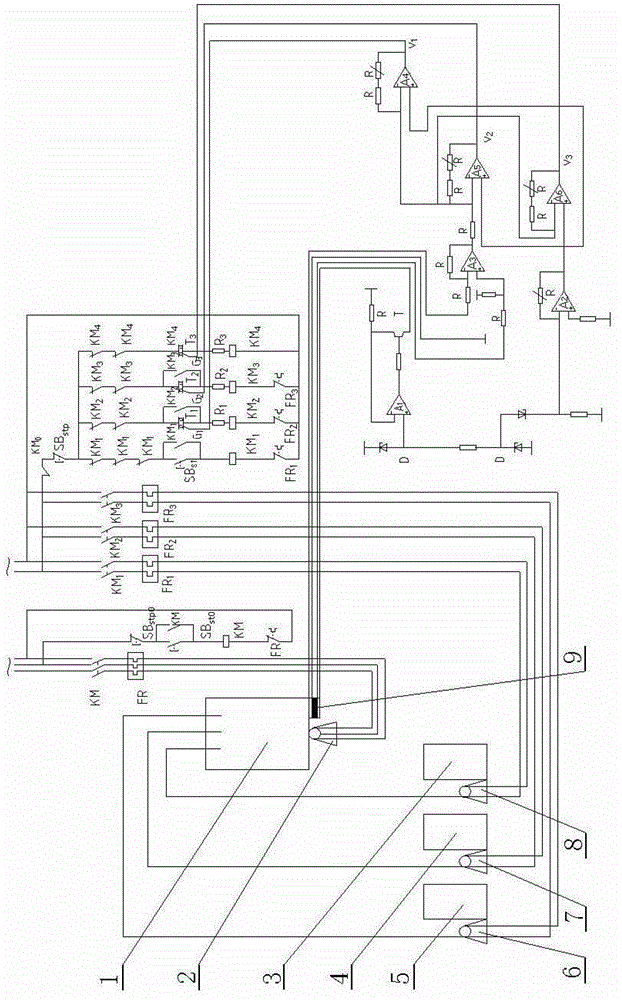

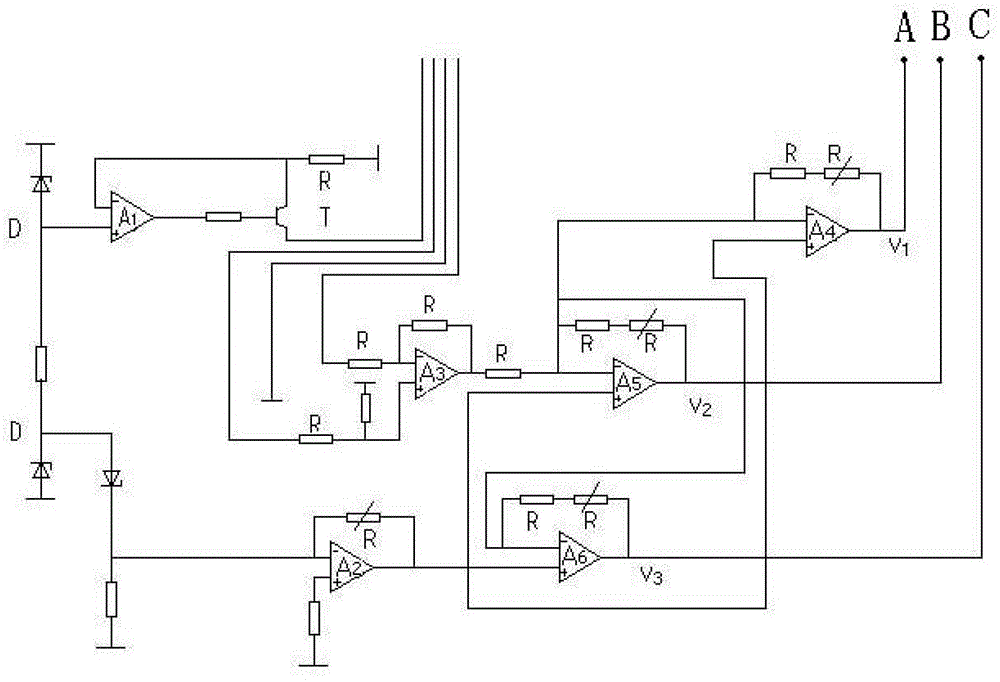

[0041] As shown in the accompanying drawings, a control device for automatically dispensing glue includes a load cell 9 installed at the bottom of the glue mixing container 1, a signal processing circuit connected to the output end of the load cell 9, and a signal processing circuit connected to the output end of the signal processing circuit. The strong and weak current coupling circuit, and the strong current control circuit connected with the feed pump of the raw material tank; the output end of the strong and weak current coupling circuit is connected with the input end of the strong current control circuit; the signal processing circuit It includes a temperature compensation circuit and a two-stage differential amplifier circuit; the strong and weak current coupling circuit is provided with a bidirectional thyristor; the load cell 9 is a resistance strain sensor with a Wheatstone bridge inside to convert the resistance change signal It is a voltage / current signal; the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com