A solid-phase double-dynamic enzymolysis fermentation process for animal-derived organic matter

A technology of animal origin and fermentation process, which is applied in the field of fermentation to achieve the effects of easy operation, saving time, cost and energy consumption, and improving the quality of fur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

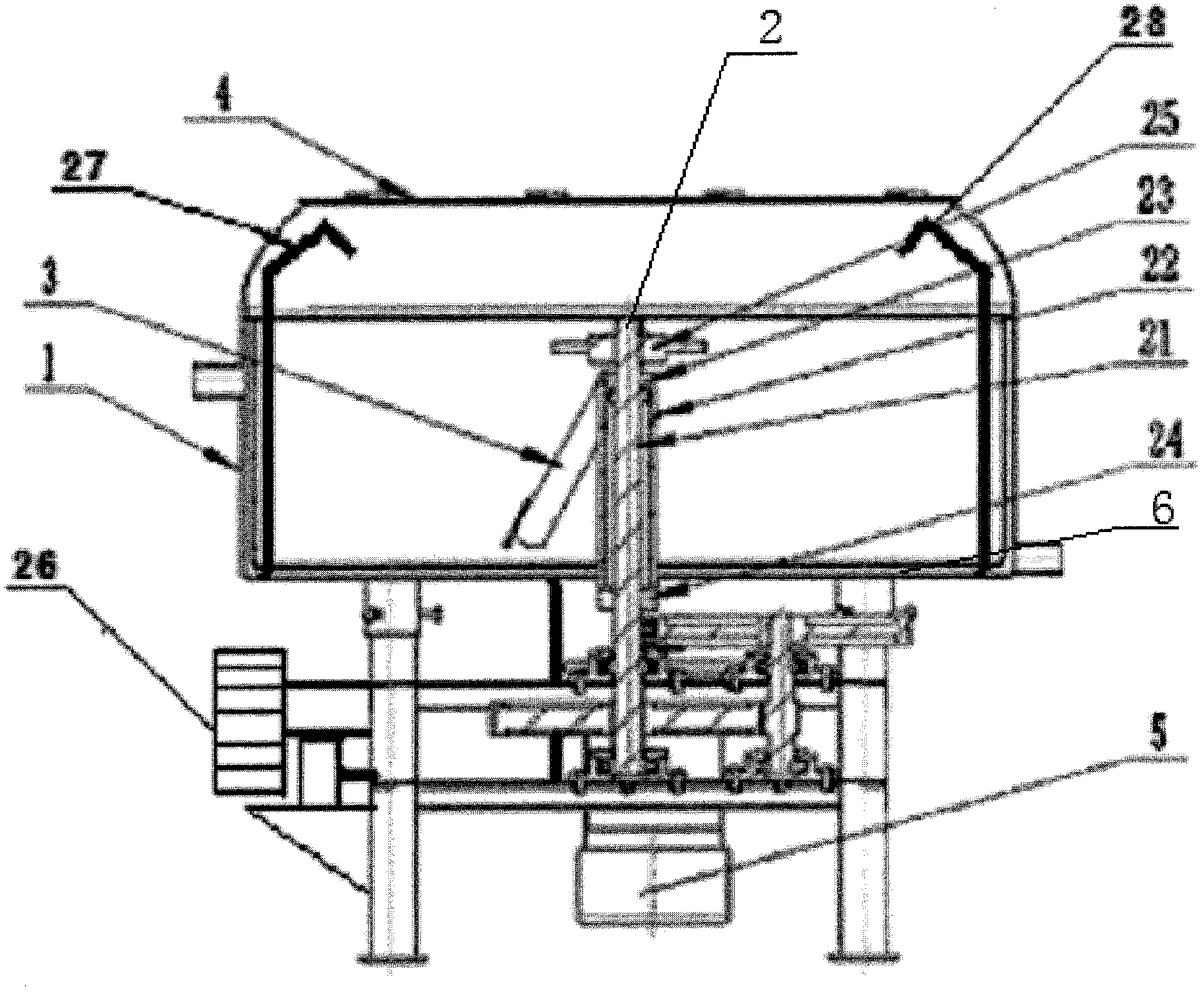

[0049] Such as figure 1 , figure 2 As shown, the solid-phase double-dynamic enzymolysis fermentation device includes a housing 1 and a stirring shaft 2 installed in the housing 1, the stirring shaft 2 is connected to the drive motor 5, and the stirring shaft is provided with a stirring shovel 3. The upper end of the housing 1 is provided with an end cover 4, and the lower end is provided with a base plate 6, and the stirring shaft 2 is mounted on the base plate 6 of the housing 1 through a bearing, as image 3 , Figure 4 As shown, the stirring shaft 2 includes a central shaft 21, a shaft sleeve 22 that is sleeved on the central shaft 21 through a bearing, and an upper gland 23 and a lower gland are arranged between the two ends of the shaft sleeve 22 and the central shaft 21 24. The upper disc 25 is fixedly connected to the top of the central axis 21. The mixing shovel 3 includes a cylindrical shovel handle 301, a flat shovel head 302 fixedly connected to the lower end of ...

Embodiment 2

[0054] Fermentation of sick and dead chickens:

[0055] Bacteria propagation: open the warehouse door, turn on the manual stirring, put in 15% of the total amount of materials in turn rice husk powder matrix, 0.1% by weight of special bacteria for animal-derived waste, fully stir evenly, then gradually add water to stir evenly, control The moisture content of the material is about 40%, that is, hold the material lightly, so that there is water between the fingers, but it is better not to drip, close the door, start the automatic stirring and automatic oxygenation at regular intervals, that is, stir for 10 minutes every 2 hours, and cultivate for 6 to 12 hours , until it has a slightly sweet and sour taste;

[0056] Harmless treatment: After the bacteria have multiplied, open the door, start manual stirring, put in 75% of the total amount of sick chickens, add 9.9% of the total amount of sawdust and continue to mix evenly, airtight and stir evenly, open Timing automatic stirri...

Embodiment 3

[0059] Sick and dead pig fermentation:

[0060] Bacteria propagation: open the warehouse door, start manual stirring, put in 15% rice husk powder and 0.1% by weight of special bacteria for animal-derived waste in turn, stir well, and then gradually add water and stir evenly to control the material The water content is about 40%, that is, gently hold the material, so that there is water between the fingers, but it is not dripping. Close the door, start the automatic stirring and automatic oxygenation at regular intervals, that is, stir for 10 minutes every 2 hours, and cultivate for 6 to 12 hours. When it has a slightly sweet and sour taste;

[0061] Pre-crushing treatment of sick and dead pigs: pre-crushing sick and dead pigs through a pre-crushing device;

[0062] Harmless treatment: After the strains have proliferated, open the warehouse door, start manual mixing, put in 75% of the pre-crushed material, add sawdust or straw powder, and continue to mix evenly. After airtigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com