A new type of banana harvesting trolley

A banana and trolley technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of no electric cutting, banana harvesting device, banana harvesting stop, labor-intensive, etc., to ensure independence and stability The effect of reducing frictional resistance and avoiding falling injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

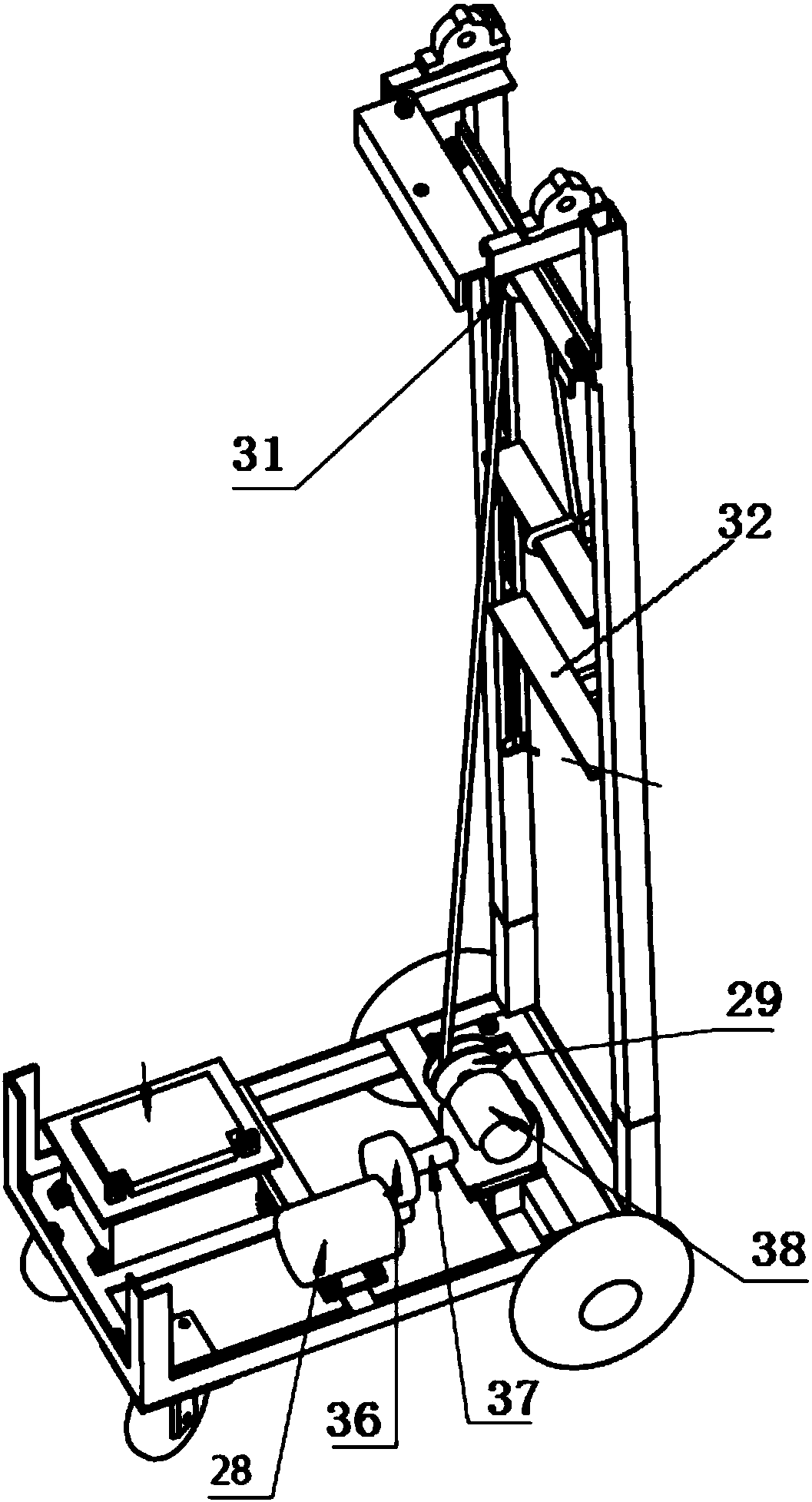

[0031] A novel banana harvesting trolley, comprising a vehicle frame 1, a cutting mechanism and a grabbing mechanism,

[0032] The cutting mechanism comprises a knife rest 2, a first motor 3, a connecting block 4, a first transmission mechanism, a first rotating shaft 5, a cutter head 6, a handle 7, a slider 8, a chute 9 and a second rotating shaft 10, and the knife rest 2. The bottom is connected to the connection block 4 through the fastener 11, the connection block 4 is connected to the slider 8 through the first rotating pair 12, the slider 5 is installed in the chute 9, and the chute 9 is fixed on the second shaft 10 , the two ends of the second rotating shaft 10 are installed on the top of the vehicle frame 1 through bearings and bearing seats; the first rotating shaft 5 is installed on the front end of the tool holder 2 through bearings, one end of the first rotating shaft 5 is fixed with a cutter head 6, and the other end of the first rotating shaft 5 passes through Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com