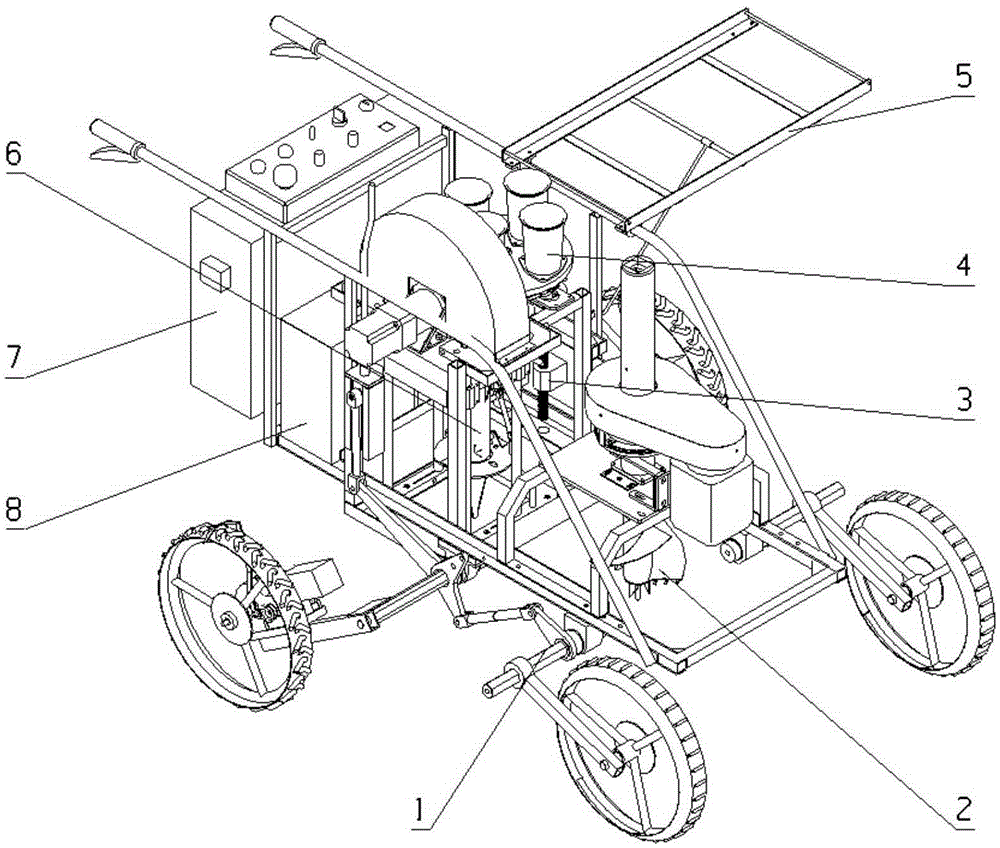

Electric rotating digging self-propelled tobacco seedling transplanter

An electric rotation and transplanting machine technology, applied in the direction of transplanting machinery, planting methods, applications, etc., can solve the problems of unstable transplanting distance, low production efficiency, high planting cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

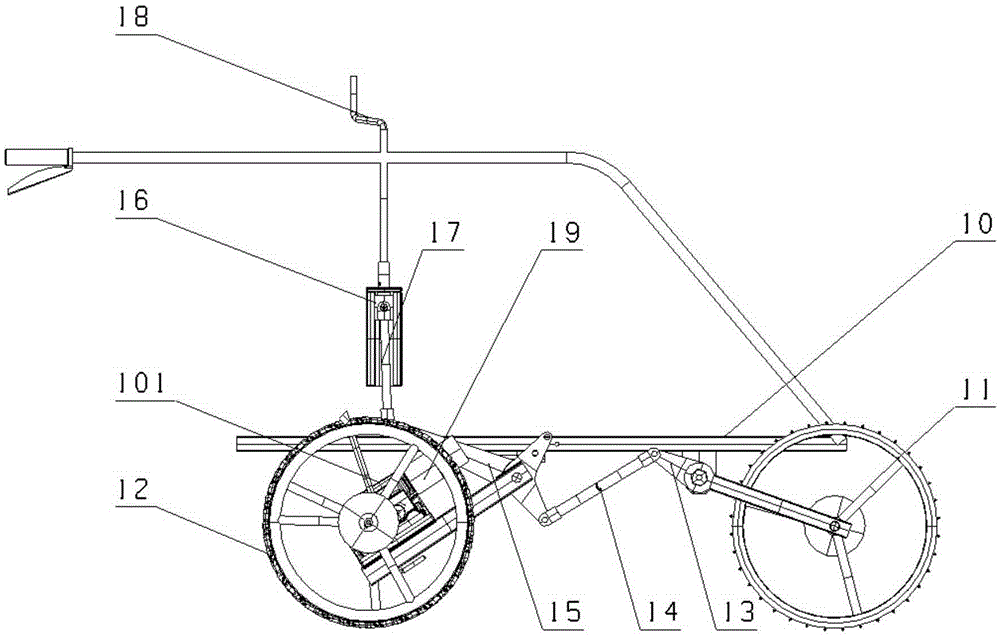

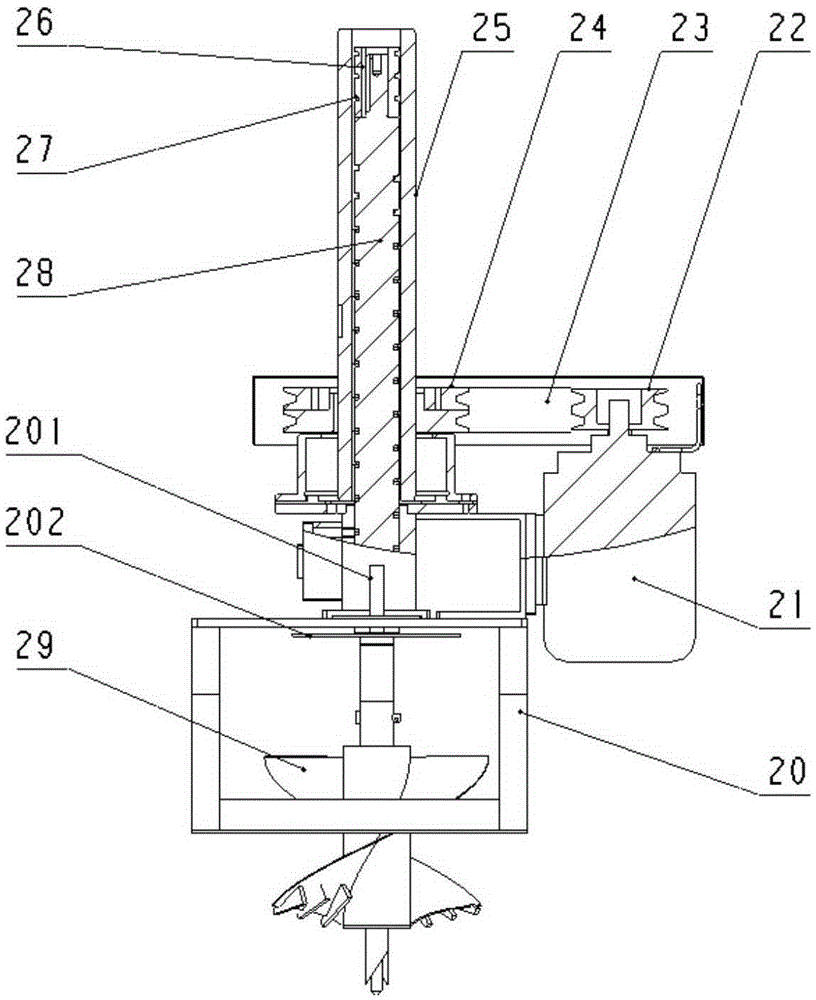

[0029] Example 1: The electric rotary pond self-propelled tobacco seedling transplanter is placed in the farmland where the ridges have been ploughed. According to the specifications of the ridges in the farmland, the adjustable handle on the adjustable frame can be rotated to raise or lower the transplanter. overall height. In line with the actual ridge requirements, confirm that the lithium battery and the control system circuit are well connected, turn the electric door lock to the "on" position, confirm that the emergency stop button has been pulled up, press the reset button, and observe that the fault code is displayed as "0", which proves that The transplanter control system is in normal state and can be operated. Pull up the seedling tray placement rack, fix the position with a support rod, place the seedling tray full of tobacco seedlings on the seedling tray placement rack, and pre-fill the seedling cup with tobacco seedlings to prepare for work. Select the plant di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com