Hot chamber caster for aluminum alloy

An aluminum alloy and casting machine technology, which is applied in the field of hot chamber casting machines for aluminum alloys, can solve the problems of large melting furnaces, achieve simple maintenance and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

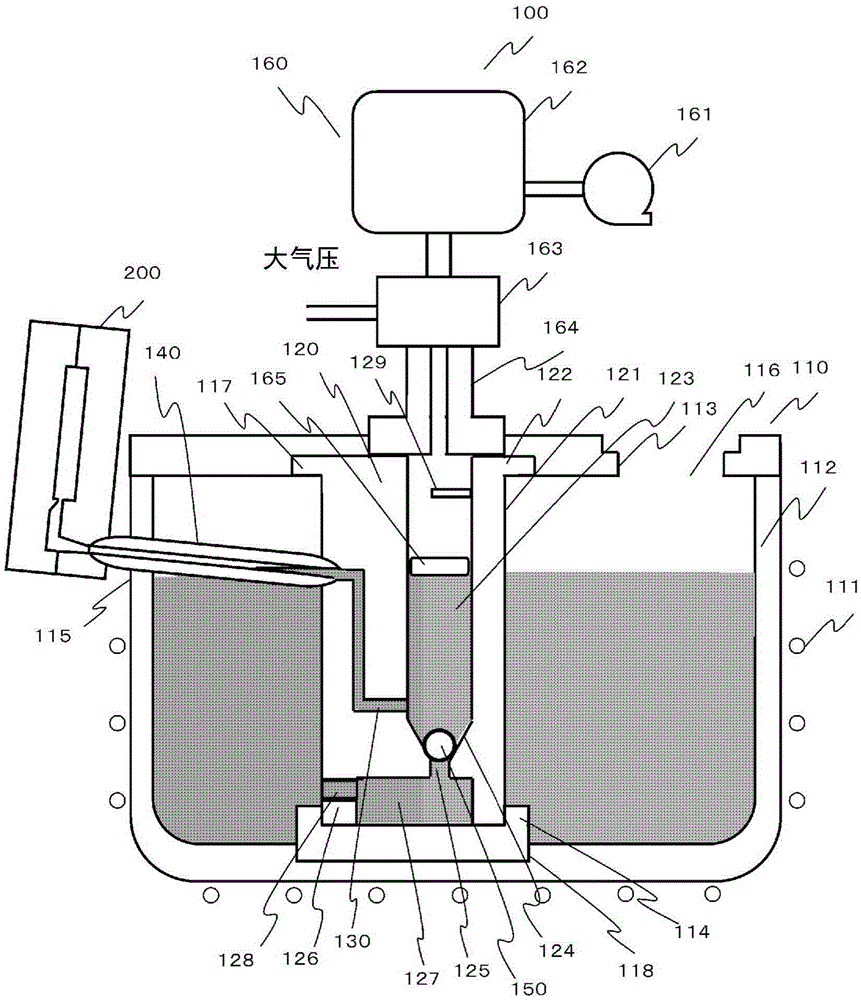

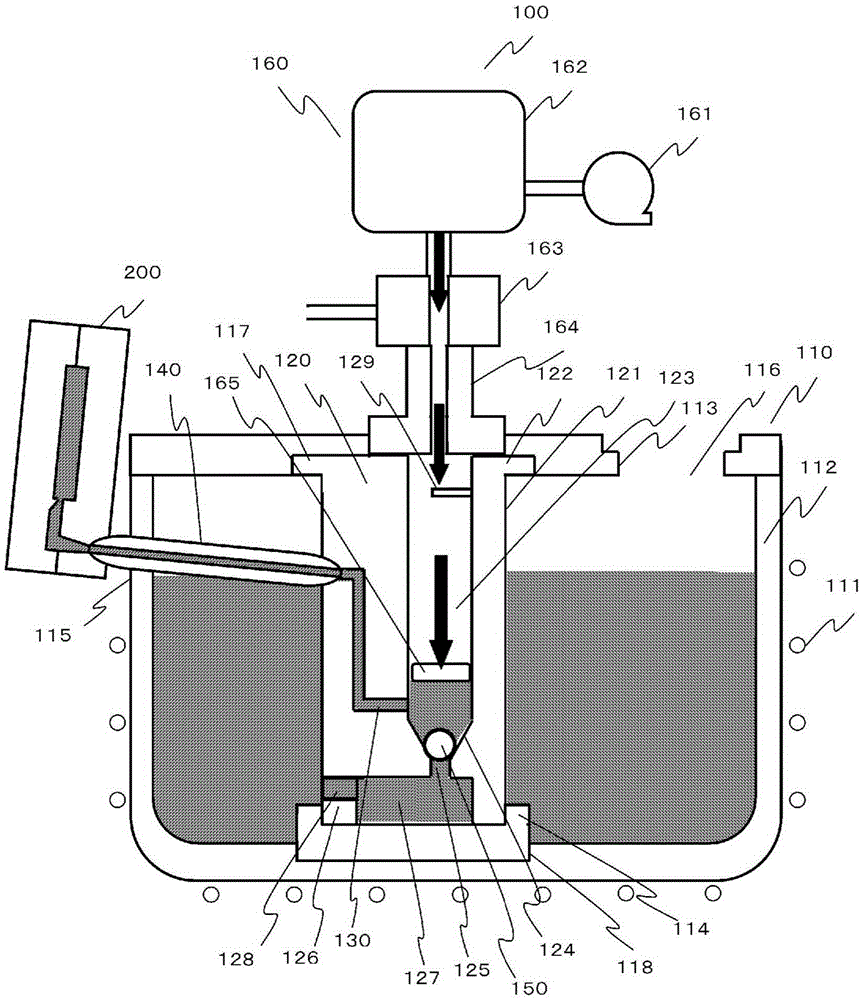

[0052] figure 1 It is a figure which simply shows the structural example of the hot chamber casting machine 100 for aluminum alloys of this invention.

[0053] exist figure 1 In order to make the internal structure easy to understand, each member is shown in longitudinal section. exist figure 1 In FIG. 1 , only the members necessary for understanding the present invention are shown, and some other members may not be shown.

[0054] exist figure 1 In the structural example of , the hot chamber casting machine 100 for aluminum alloy includes a melting furnace 110 , a molten metal injection main cylinder section 120 , an injection path 130 , a nozzle 140 , a valve body 150 , and a gas pressurization section 160 . Moreover, the mold 200 is shown together.

[0055] The melting furnace 110 is equipped with a heating device 111 and a crucible 112 for storing molten metal obtained by melting the metal material. A lid member 113 is disposed on the top surface of the crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com