Circulating fluidized bed boiler ignition device with natural gas serving as fuel

A circulating fluidized bed and boiler ignition technology, which is applied in the directions of combustion ignition, fluidized bed combustion equipment, and fuel burning in a molten state, to achieve the effects of sufficient combustion, reducing the cost of ignition, and realizing low-carbon emissions.

Inactive Publication Date: 2016-02-17

XIAN GERUIDE NEW CHEM MATERIALS CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the above-mentioned existing shortcomings, the main purpose of the present invention is to provide a practical ignition device for circulating fluidized bed boilers using natural gas as fuel, which uses natural gas to ignite, reduces the cost of starting the furnace, and reduces the maintenance workload of the furnace. Improve economic benefits, realize low-carbon emissions during the ignition process of this type of boiler, and eliminate carbon deposits and clogging of nozzles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

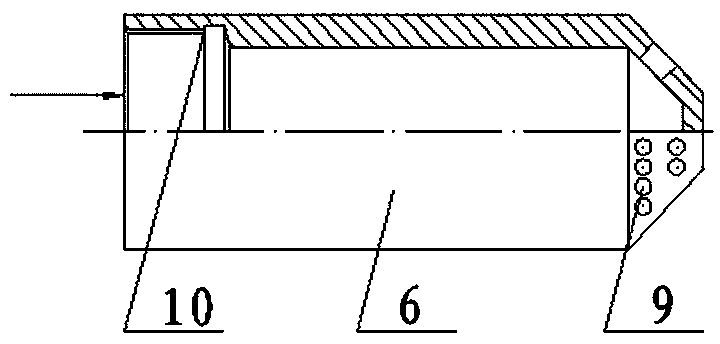

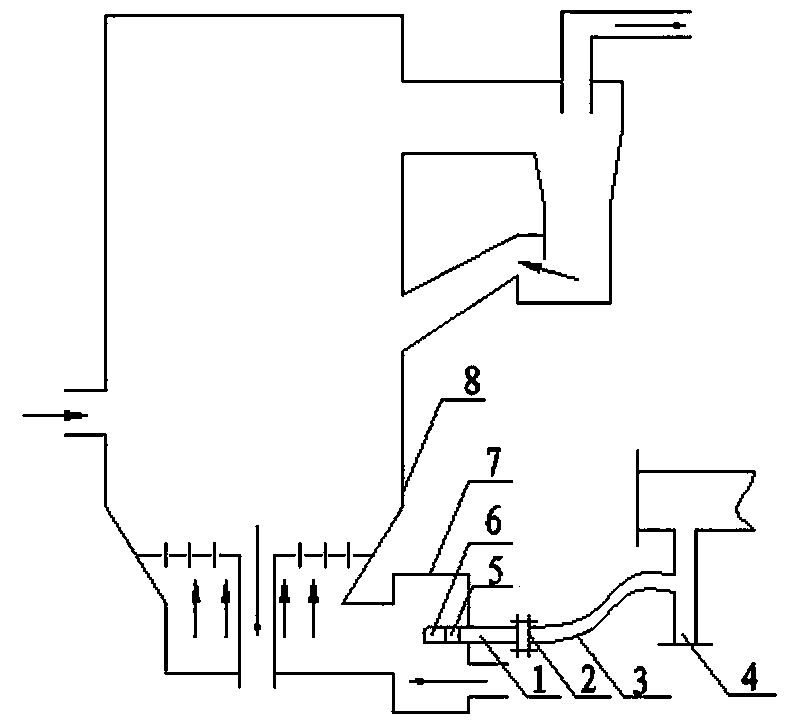

The invention discloses a circulating fluidized bed boiler ignition device with natural gas serving as fuel. The ignition device comprises an ignition combustor, a natural gas nozzle and a metal hose. The ignition device is characterized in that a body of the natural gas nozzle is a hollow stainless steel bar in the shape of a cylinder and a circular truncated cone; the circular truncated cone part is a sprayer, and natural gas spray holes are evenly distributed in the circular truncated cone part; the tail end of the cylinder part is connected with a short section through a thread structure, the other end of the short section is in threaded connection with a section of stainless steel pipe, the other end of the stainless steel pipe is connected with the front end of the metal hose in a sealed manner through a connecting flange, and the other end of the metal hose is connected with a natural gas input pipeline; and the body of the natural gas nozzle and the short section are integrally arranged in the ignition combustor. Natural gas is adopted for ignition, boiler ignition cost is reduced, the boiler ignition maintenance workload is reduced, economic benefits are increased, the low-carbon emission in the ignition process of the boiler of the type is achieved, and the phenomena of carbon deposition and blockage of the nozzle are eliminated.

Description

technical field The invention relates to an ignition device for a circulating fluidized bed boiler using natural gas as fuel. Background technique At present, most circulating fluidized bed boilers use light diesel as ignition fuel, which is ignited after being atomized by an oil gun. In today's high oil price, the ignition cost is very high, which greatly increases the expenditure of enterprises. Moreover, during the combustion process of diesel oil, it is very easy to generate carbon deposits at the nozzle of the oil gun and block the nozzle, so that the ignition of the oil gun that is being ignited cannot be continuously injected, causing ignition interruption, which brings difficulties to the ignition of the boiler. Moreover, the occurrence of ignition interruption will slow down the temperature rise of the furnace, resulting in a large amount of fuel heat loss and increasing the cost of ignition. Contents of the invention In order to solve the above-mentioned existi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23C10/18F23Q13/02

Inventor 李小敏吴倩

Owner XIAN GERUIDE NEW CHEM MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com