Lubrication and adjustment valve body

A technology for regulating valves and valve bodies, which is applied to valve details, valve devices, and valve housing structures, and can solve problems such as difficult assembly, large spring compression, and inability to adjust and control spring preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

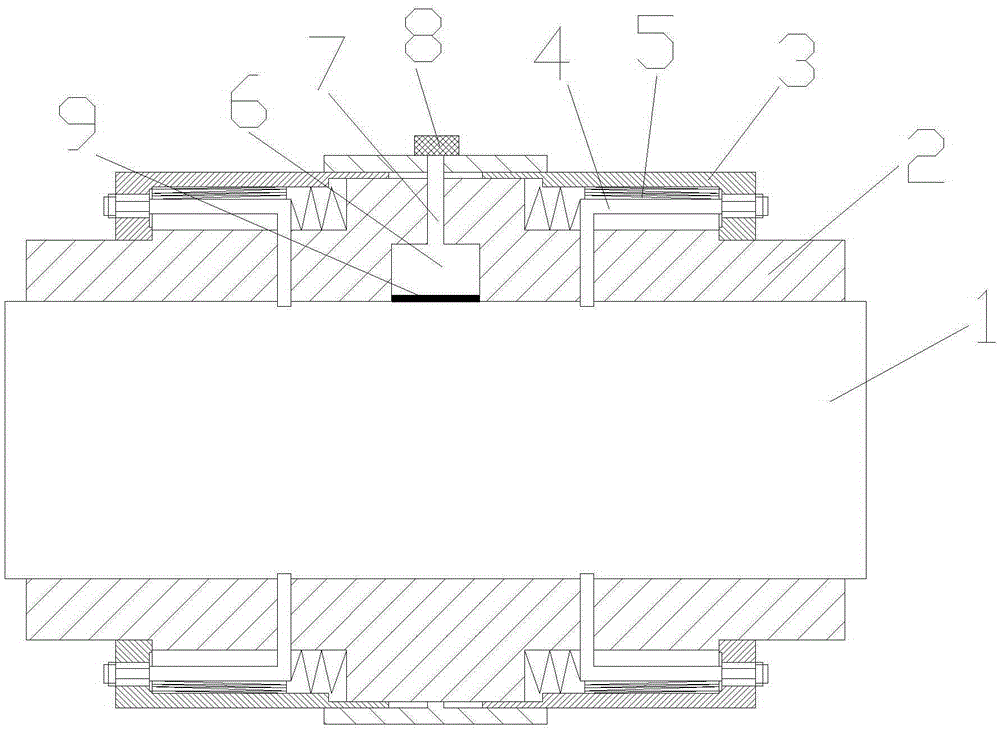

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 A lubricating regulating valve body according to the present invention, comprising a valve body 1 and a valve seat 2; the valve body 1 is installed in the valve seat 2; the valve seat 2 is provided with an adjustment seat 3; the adjustment seat 3 There is an adjustment curved rod 4 inside; one end of the adjustment curved rod 4 extends out of the adjustment seat 3, and the other end extends into the inside of the valve body 1; a compression spring 5 is provided between the adjustment curved rod 4 and the inner wall of the adjustment seat 3; The upper end of the valve body 1 is provided with an oil storage tank 6; the oil storage tank 6 is connected to the outside of the valve body 1 through the oil guide passage 7 and sealed with a sealing cover 8; the bottom of the oil storage tank 6 is provided with an oil seepage film 9; the adjustment There are four seats 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com