Environment-friendly light building formwork and manufacturing method

A technology of building formwork and polypropylene, which is applied in the field of building formwork and its preparation, which can solve the problems of easy aging, insufficient strength and rigidity of the formwork, large coefficient of thermal expansion and contraction, etc., and achieve the effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

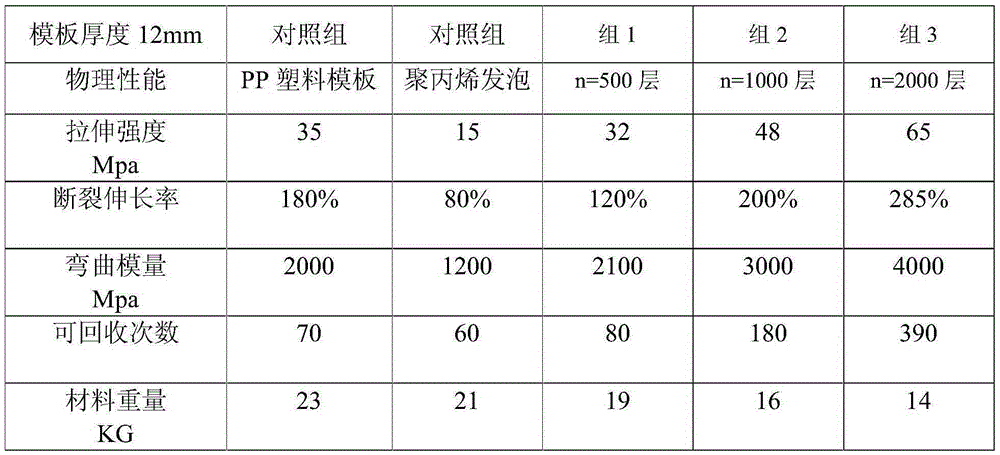

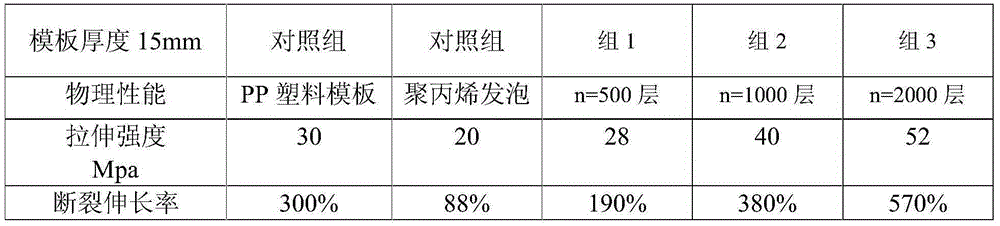

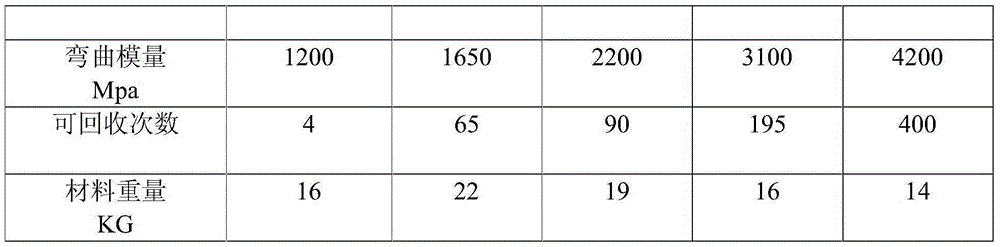

Examples

Embodiment 1

[0022] A building formwork, the components are calculated by weight parts: A 5-10 parts of glass fiber reinforced polypropylene, 80-90 parts of high melt strength polypropylene, C-homopolypropylene or 30% calcium carbonate polypropylene 10-30 parts, D-foaming agent 3-8 parts, E-color masterbatch 1-4 parts.

[0023] Its preparation method is as follows:

[0024] (1) Put A into the A extruder and extrude through mixing and plasticizing, high melt strength polypropylene (HMSPP) is added into the foaming agent and then put into the hopper of the B extruder and extrude through mixing and plasticizing, and C is put into C Extruded through mixing and plasticizing in the hopper of the extruder;

[0025] (2) Divide B extrudate and C extrudate obtained in step (1) into double-layer composites of B and C through a distributor, and then enter a superposition machine to superimpose and extrude a superimposed layered composite of 16-3000 layers; superimposition Composite body, A extruded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com