Polyurethane sealant and preparation method and application thereof

A polyurethane sealant and reactor technology, applied in the field of sealant, can solve problems such as peeling of sealant, high tensile modulus, damage to the joint surface, etc., and achieve the effects of prolonging service life, reducing modulus, and shortening maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

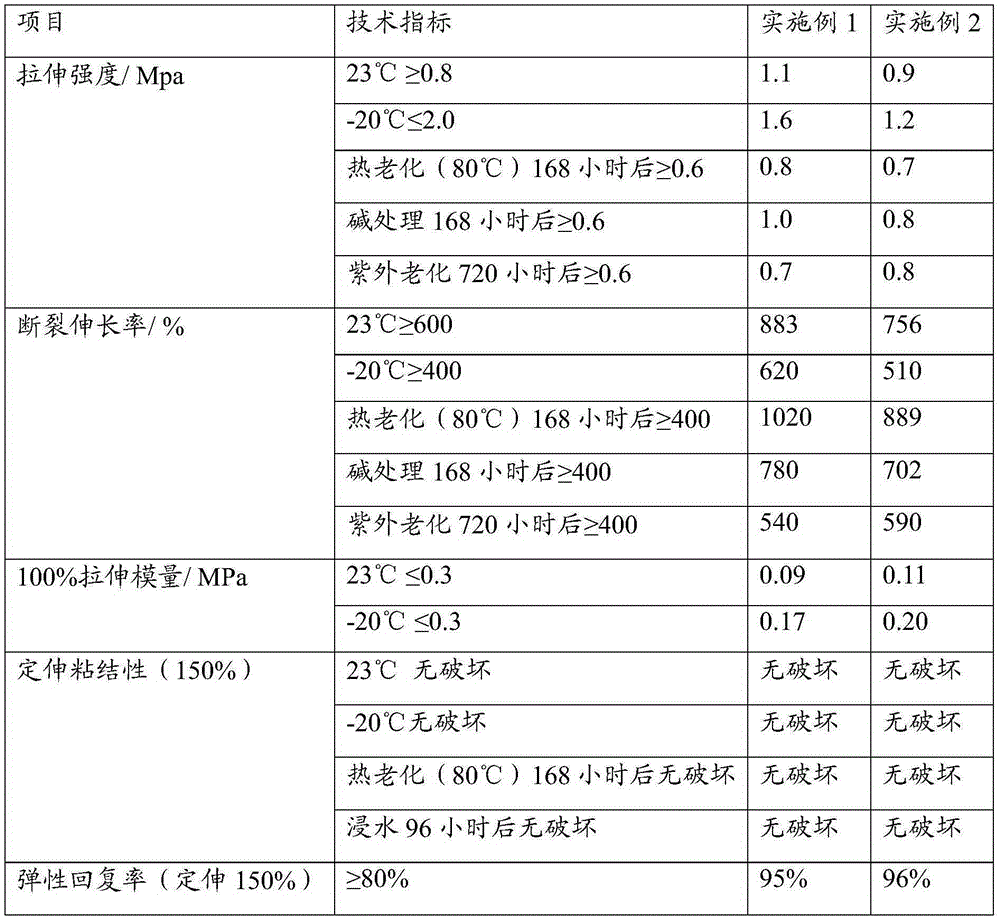

Examples

Embodiment 1

[0036] This embodiment provides a polyurethane sealant, the specific preparation method is as follows:

[0037] Prepare component A:

[0038] 70 parts of polyether polyols (including 40 parts of polyether diols, Dow Chemical 2000LM, 30 parts of polyether trihydric alcohols, Dow Chemical 2471) and 6 parts of plasticizer (diisooctyl phthalate ester) into the first reactor, stirred and heated to 110-120°C, heat-preserved and vacuumed until the moisture content in the reactor is less than 0.05wt%, wherein, the time for heat-preserved and vacuumed is 0.5-1 hour;

[0039] Cool the above reactor to 70°C and add 24 parts of TDI, stir at this temperature for 10-30 minutes, then continue to heat up to 80±2°C, keep warm for 2-3 hours, then cool down to obtain component A.

[0040] Prepare B component:

[0041] Add 47 parts of liquid filler (including 37 parts of diisooctyl phthalate, 10 parts of dibutyl phthalate), and 10 parts of curing agent Unilink4200 into the second reactor, and r...

Embodiment 2

[0045] This embodiment provides a polyurethane sealant, the specific preparation method is as follows:

[0046] Prepare component A:

[0047] 75 parts of polyether polyols (including 35 parts of polyether diols, Dow Chemical 2000LM, 40 parts of polyether triols, Dow Chemical 2471) and 1 part of plasticizer (diisooctyl phthalate ester) into the first reactor, stirring and heating up to 115°C, heat preservation and vacuumization until the moisture content in the reactor is less than 0.05wt%, wherein the heat preservation and vacuumization time is 40 minutes;

[0048] Lower the temperature of the above reactor to 70°C and add 24 parts of TDI, stir at this temperature for 20 minutes, then continue to raise the temperature to 80±2°C, keep it warm for 2.5 hours, then lower the temperature to obtain component A.

[0049] Prepare B component:

[0050]Mix 45 parts of liquid filler (including 30 parts of diisooctyl phthalate, 10 parts of dibutyl phthalate, 5 parts of chlorinated paraf...

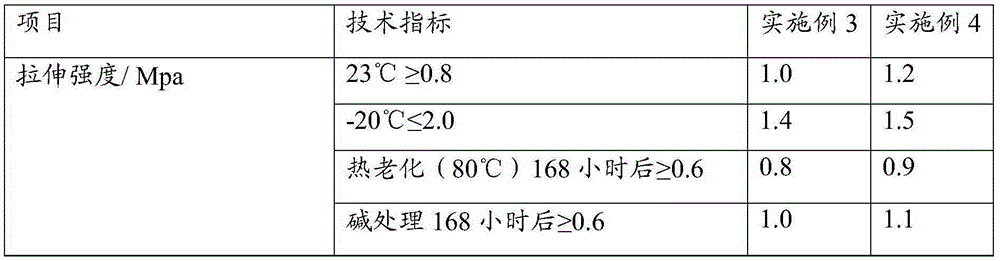

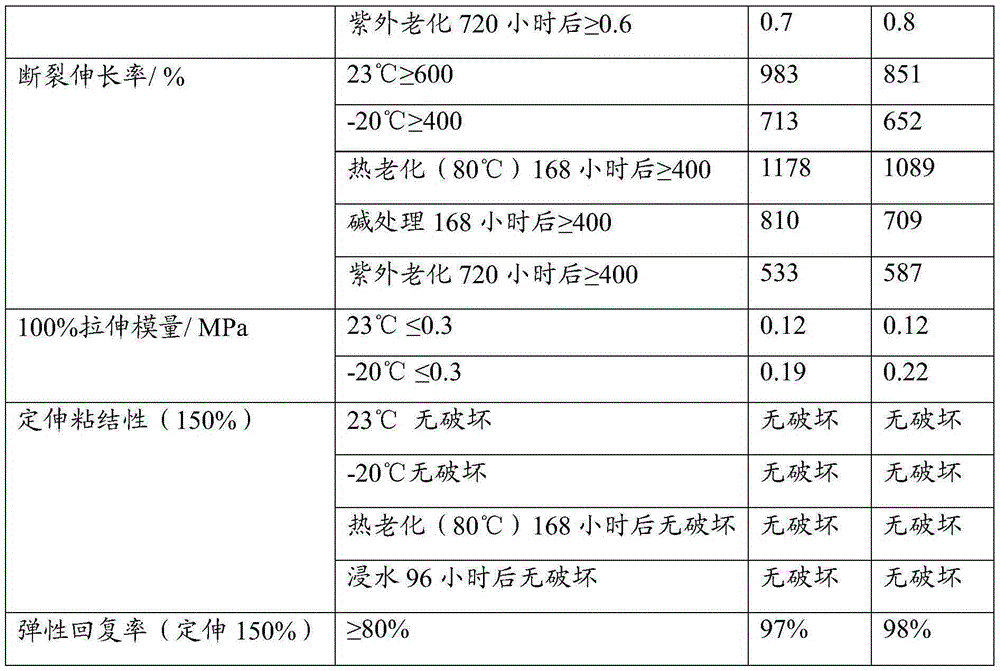

Embodiment 3

[0058] This embodiment provides a polyurethane sealant, the specific preparation method is as follows:

[0059] Prepare component A:

[0060] 60 parts of polyether polyols (including 35 parts of polyether diols, Dow Chemical 2000LM, 25 parts of polyether trihydric alcohols, Dow Chemical 2471) and 20 parts of plasticizer (diisodecyl phthalate ester) into the first reactor, stirring and heating up to 110°C, heat preservation and vacuumization until the moisture content in the reactor is less than 0.05wt%, wherein the heat preservation and vacuumization time is 0.5 hours;

[0061] Lower the temperature of the above reactor to 70°C and add 20 parts of TDI, stir at this temperature for 10 minutes, then continue to raise the temperature to 80±2°C, keep it warm for 2 hours, then lower the temperature to obtain component A.

[0062] Prepare B component:

[0063] Add 25 parts of liquid filler (including 15 parts of diisooctyl phthalate, 7 parts of dibutyl phthalate, 3 parts of chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com