Flexible weight-reducing main girder structure of a crane

A technology for cranes and main girders, which is applied in the field of flexible weight-reducing main girder structures of cranes, which can solve the problems of large box-type main girders, inconvenient transportation and installation, and high quality, so as to achieve not easy to slide left and right, easy to transport, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

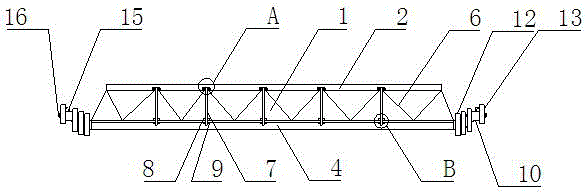

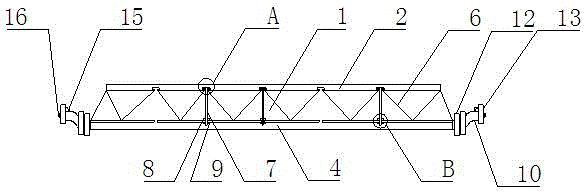

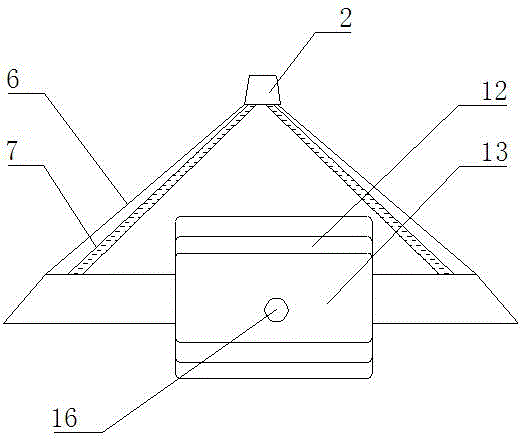

[0022] Such as Figure 1-7 As shown, a flexible weight-reducing main girder structure of a crane includes a main girder body 1, and the main girder body 1 includes an upper fixing rod 2 and a lower fixing plate 4, and the two sides of the upper fixing rod 2 are provided with Bolt groove 3, the both sides of described lower fixing plate 4 are provided with screw rod groove 5, between described upper fixing rod 2 and lower fixing plate 4, be evenly provided with oblique support bar 6, described bolt groove 3 and screw rod Bolts A7 are interspersed between the grooves 5, the upper nut 8 screwed on the bolt A7 is arranged above the screw groove 5, and the lower nut 8 screwed on the bolt A7 is arranged below the screw groove 5. Cap 9, the two ends of the lower fixing plate 4 are equipped with a flat hanging rod 10, the upper part of the end of the flat hanging rod 10 is provided with a groove 11, and a counterweight is placed on the flat hanging rod 10 12. The end of the flat hang...

Embodiment 2

[0025] Such as Figure 1-7 As shown, a flexible weight-reducing main girder structure of a crane includes a main girder body 1, and the main girder body 1 includes an upper fixing rod 2 and a lower fixing plate 4, and the two sides of the upper fixing rod 2 are provided with Bolt groove 3, the both sides of described lower fixing plate 4 are provided with screw rod groove 5, between described upper fixing rod 2 and lower fixing plate 4, be evenly provided with oblique support bar 6, described bolt groove 3 and screw rod Bolts A7 are interspersed between the grooves 5, the upper nut 8 screwed on the bolt A7 is arranged above the screw groove 5, and the lower nut 8 screwed on the bolt A7 is arranged below the screw groove 5. Cap 9, the two ends of the lower fixing plate 4 are equipped with a flat hanging rod 10, the upper part of the end of the flat hanging rod 10 is provided with a groove 11, and a counterweight is placed on the flat hanging rod 10 12. The end of the flat hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com