Full-automatic laminating machine

A laminating machine, fully automatic technology, applied in the direction of lamination equipment, lamination auxiliary operation, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the present invention will be further described in detail with reference to the accompanying drawings and embodiments, using FPC as a laminated product. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

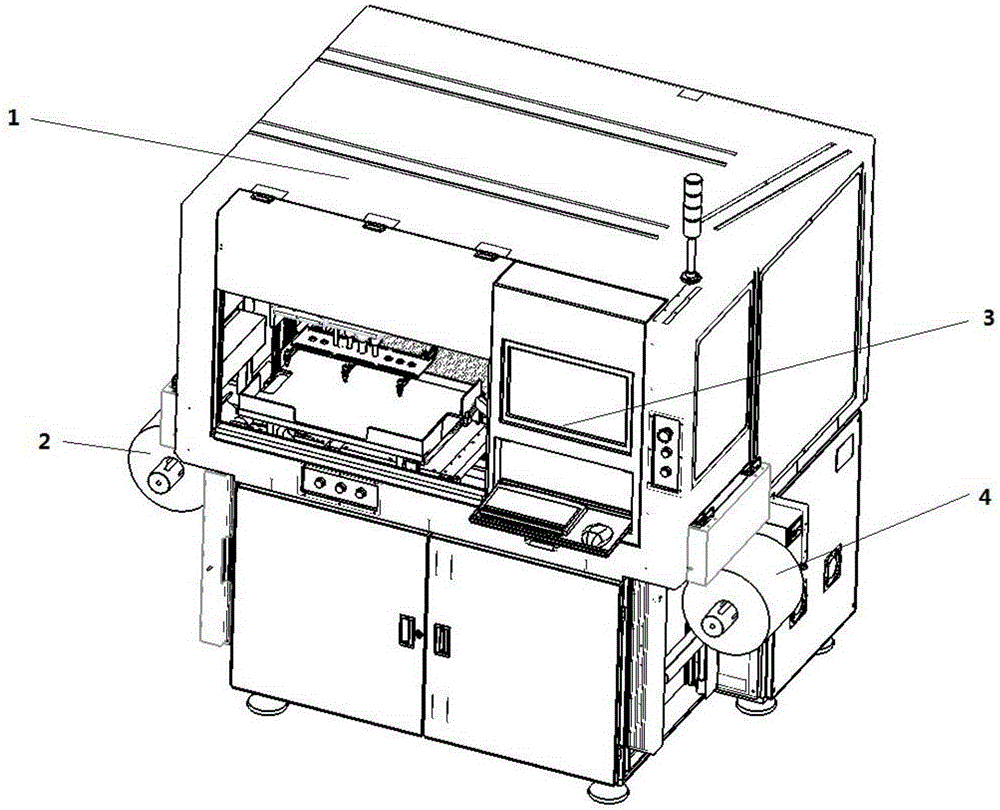

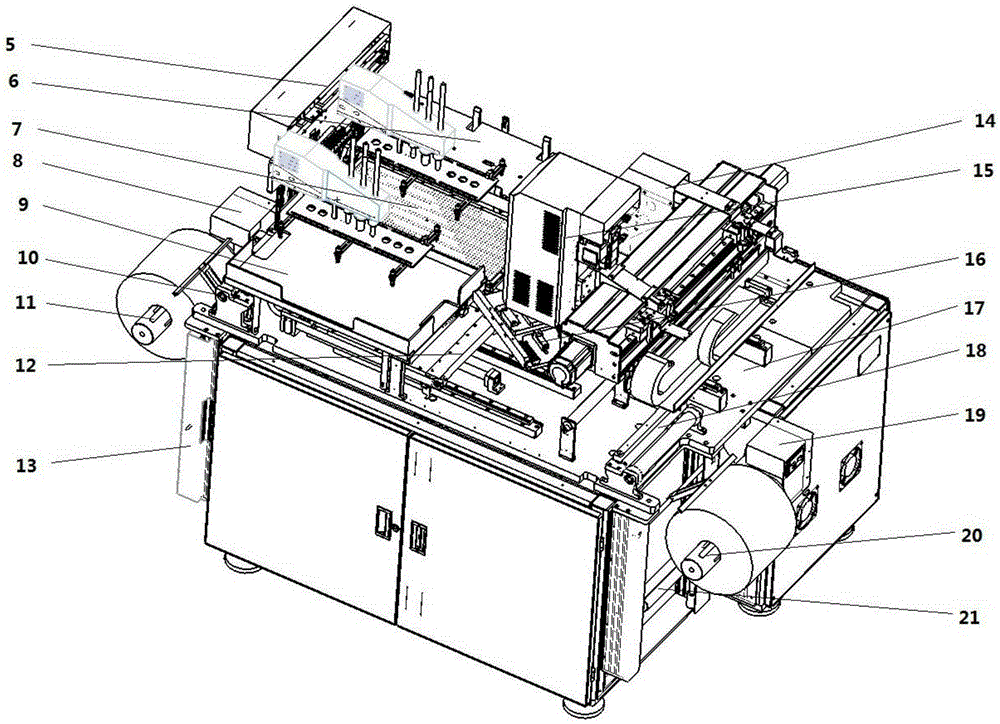

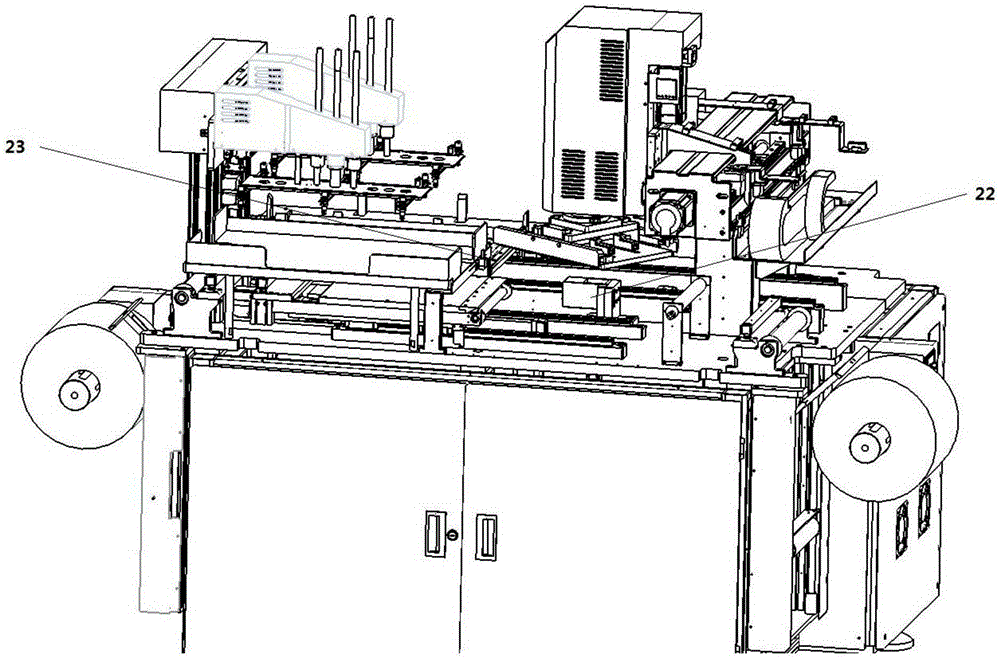

[0013] See figure 1 , figure 2 and image 3 , the fully automatic laminating machine provided by the embodiment of the present invention includes a shell assembly 1, a loading and unloading manipulator assembly 5, a loading tray assembly 6, a stage module 7, an unloading tray 9, a loading and clamping assembly 10, a stripping The material system component 12 , the FPCCCD imaging system 14 , the XZU axis motion system 15 , the unloading and clamping assembly 18 , and the covering film CCD imaging system 22 are jointly installed on the base plate 17 . The feeding control unit 8, the feeding air shaft 11, and the feeding gravity guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com