Horizontal type adjustable woodworking drilling machine

A woodworking drilling and horizontal technology, applied in the field of drilling machines, can solve the problems of high vibration intensity, poor processing quality, unstable installation, etc., and achieve the effect of low vibration intensity, reasonable structure distribution and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

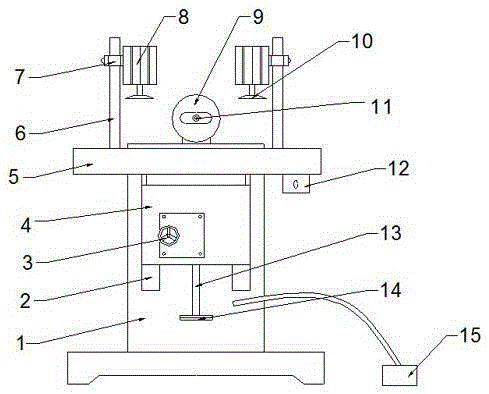

[0020] Such as figure 1 As shown, the invention discloses a horizontal adjustable woodworking drilling machine, which includes a base 1, a lifting mechanism connected to the side wall of the base 1, a workbench arranged on the upper end of the lift mechanism, a clamping mechanism and a driving mechanism above the workbench.

[0021] The base 1 is in a vertical column shape, and a pair of parallel guide rails 2 are fixed on the front end side wall by bolts, and the pair of parallel guide rails 2 are arranged in the middle of the front end side wall.

[0022] The lifting mechanism includes a pad 14, a threaded rod 13 vertically fixed on the pad by bolts, a lifting platform 4 connected to the threaded rod 13, a rotating hand wheel 3 connected to the lifting platform 4; the pad 14 is L-shaped, L The outer side of the L-shaped short side is fixed on the lower part of a pair of parallel guide rails 2 by bolts, and the outer side of the L-shaped long side is horizontally upward, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com