All-directional dust sucking and polishing workbench

A workbench and all-round technology, applied in the direction of manufacturing tools, grinding racks, grinding bed, etc., can solve the problems of easy dust flying around, poor dust collection effect, small dust collection space in drawers, etc., to achieve ash collection Convenience, large dust storage capacity, and large ash storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

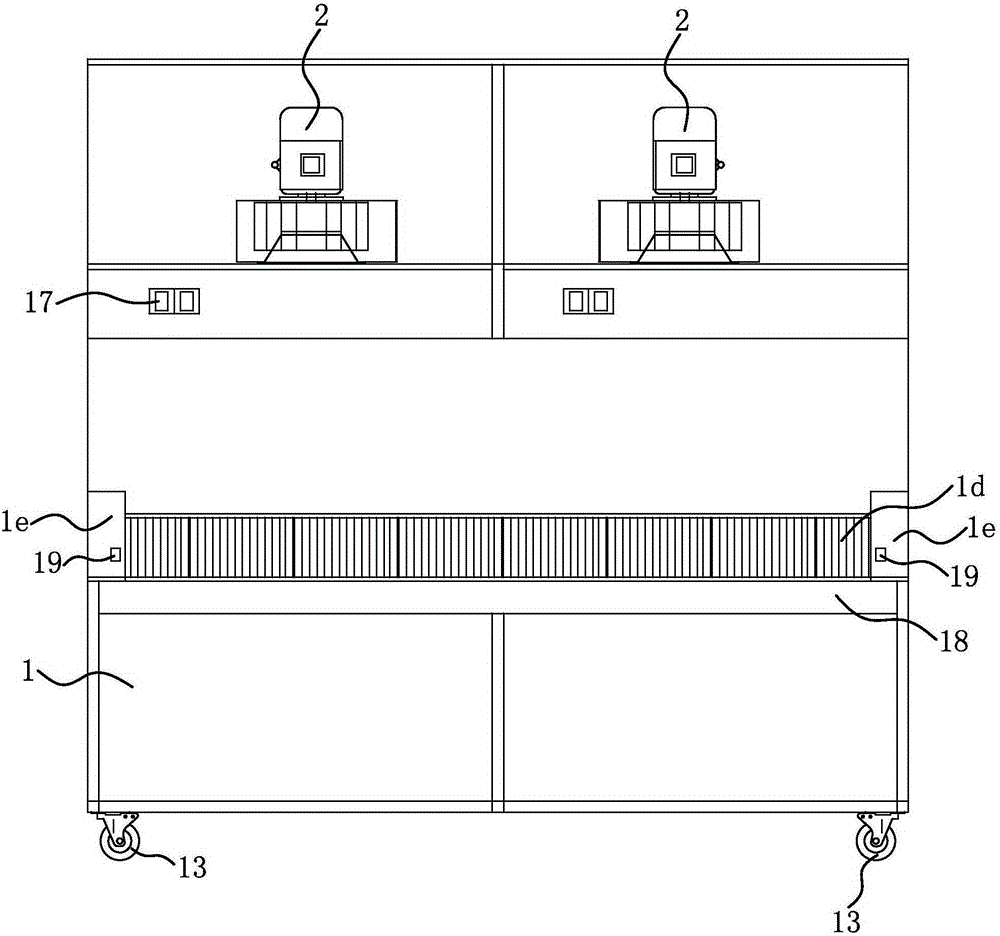

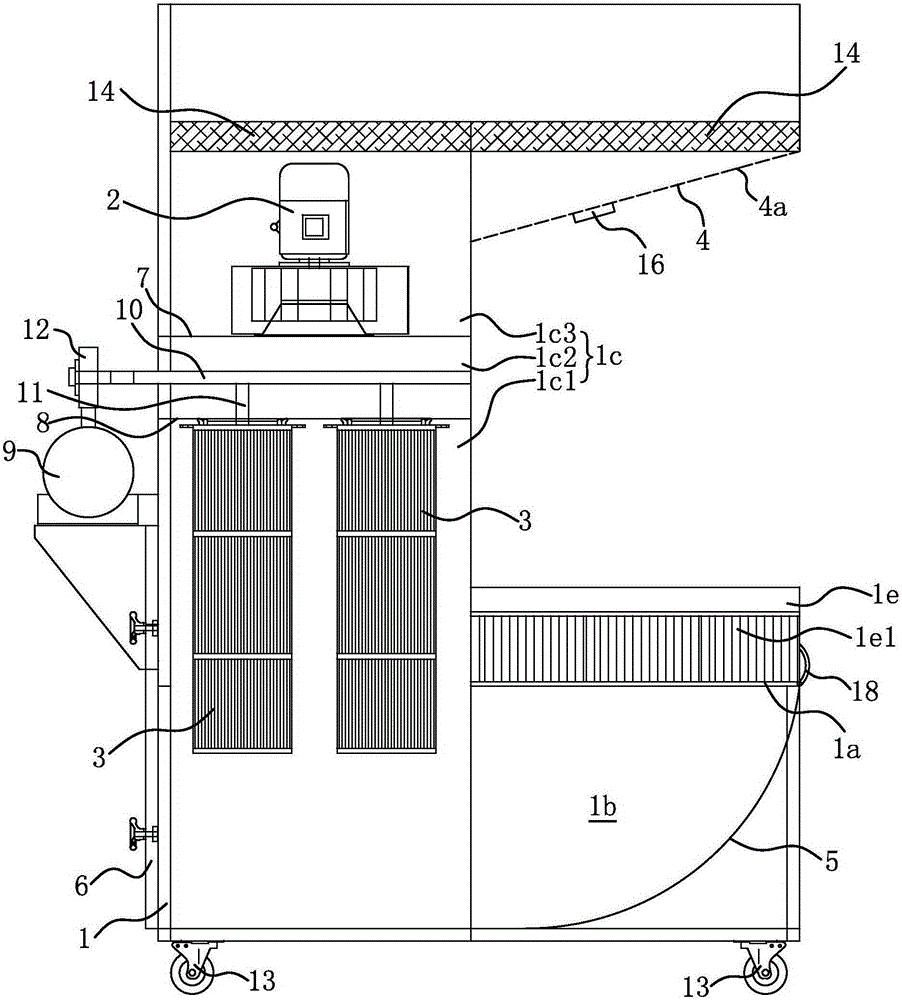

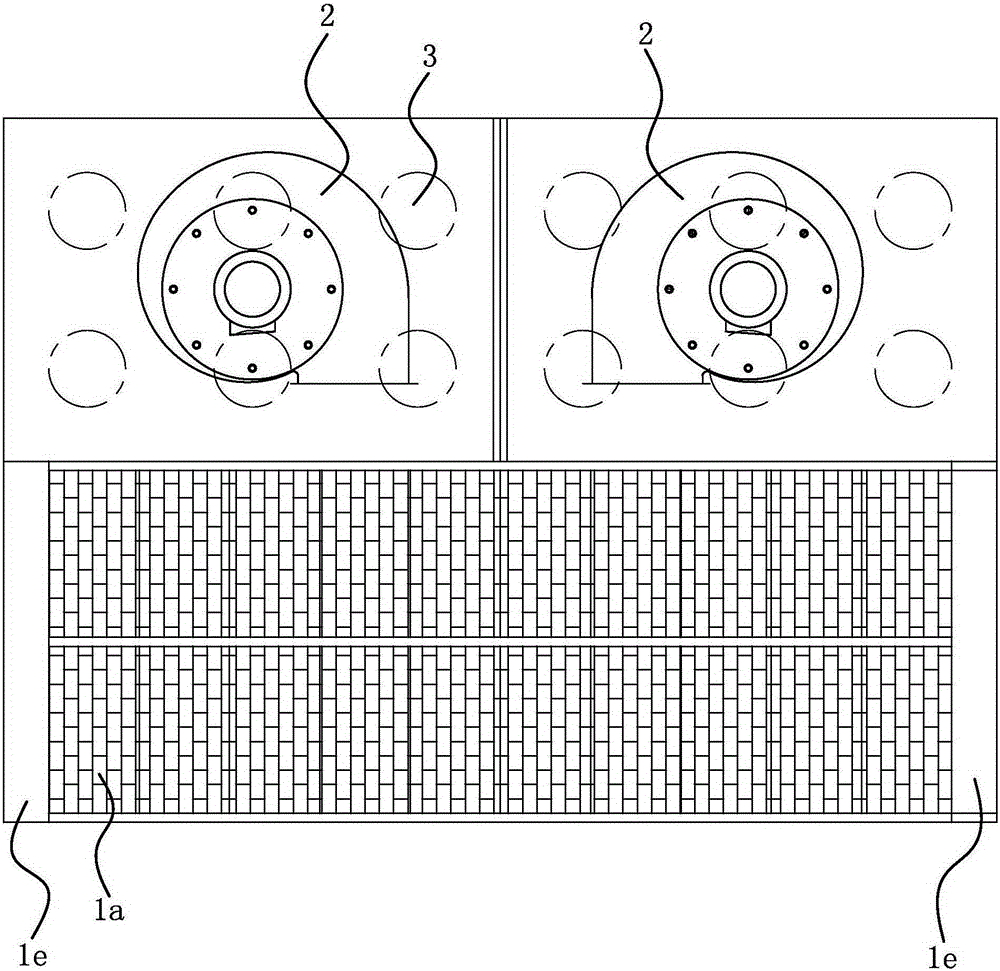

[0027] like Figure 1 to Figure 4 As shown, the all-round vacuuming and polishing workbench includes a workbench cabinet 1, a blower fan 2 and a filter cartridge 3.

[0028] The workbench cabinet 1 includes a frame and structural panels, and the workbench cabinet 1 is a hollow structure. The middle part of the workbench cabinet 1 has a workbench 1a, and the workbench 1a is used to place workpieces or workpiece fixtures. In other words, the workpiece is positioned on the workbench 1a when the workpiece is polished. The worktable 1a is made of grids, which can not only form a plurality of first dust suction ports, but also effectively support workpieces.

[0029] The top of the workbench cabinet 1 has a top plate 4 located directly above the workbench 1a. The top plate 4 is inclined to the front side, and the top plate 4 is provided with a return air hole 4a. An illuminating lamp 16 is fixed on the top board 4 . A plurality of casters 13 are fixed on the bottom surface of th...

Embodiment 2

[0041] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities will not be described in detail, and only the differences will be described. The dust guide plate 5 fixedly connected to the cabinet 1; the ash removal door 6 is arranged on the front side wall of the ash storage chamber 1b.

Embodiment 3

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 5 As shown, the top plate 4 is arranged horizontally, and the number of high-efficiency filter plates 14 is only one row, and one row is located above the fan 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com