Piezoelectric series plunger jet dispensing device

A tandem, jet-point technology, applied to devices and coatings that apply liquid to surfaces, can solve problems such as changes in liquid properties, nozzle wear, and increased maintenance costs for non-contact jet-dispensing devices, achieving extended use. life, reduce maintenance costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

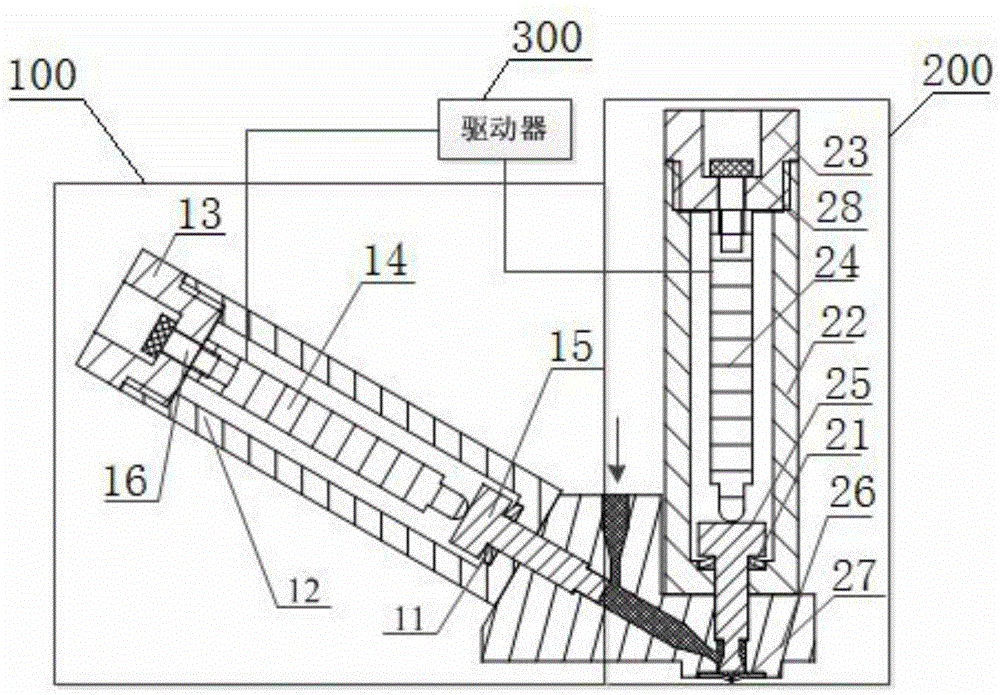

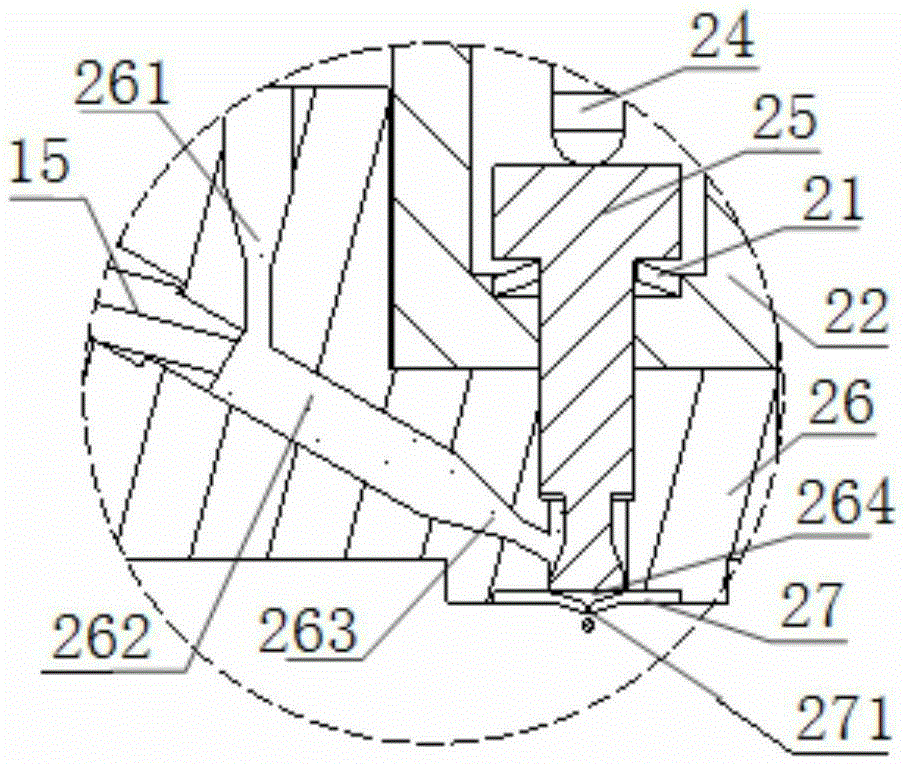

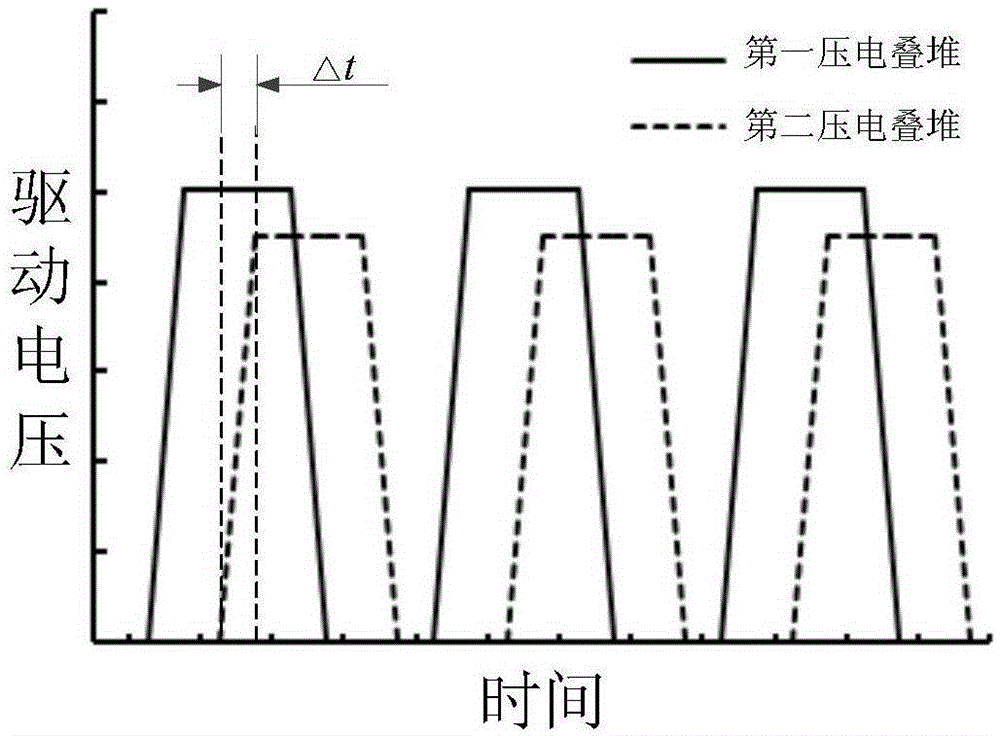

[0020] Such as figure 1 As shown, the present invention discloses a piezoelectric tandem plunger jet dispensing device, including a glue supply system 100 and an injection system 200, and the piezoelectric tandem plunger jet dispensing device also includes a driver 300 for sending a driving signal , the glue supply system 100 includes a first spring 11, a first cavity 12, a first preload nut 13, a first piezoelectric stack 14 and a first plunger 15, and the first preload nut 13 is installed in the first cavity 12, the first piezoelectric stack 14 is located in the first cavity 12, the first piezoelectric stack 14 is located between the first preload nut 13 and the first plunger 15, and the first spring 11 is arranged in the first The lower end surface of the plunger 15; the injection system 200 includes a second spring 21, a second cavity 22, a second preload nut 23, a second piezoelectric stack 24, a second plunger 25, a glue seat 26 and a nozzle 27 , the second preload nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com