Self-checking system and self-checking method for range hood capable of regulating wind speed automatically

A range hood, automatic speed regulation technology, applied in the direction of removing oil fume, heating method, lighting and heating equipment, etc., can solve problems such as harmful to human health, lack of scientific accuracy, pollution of kitchen sanitation environment, etc., and achieves easy installation and design structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

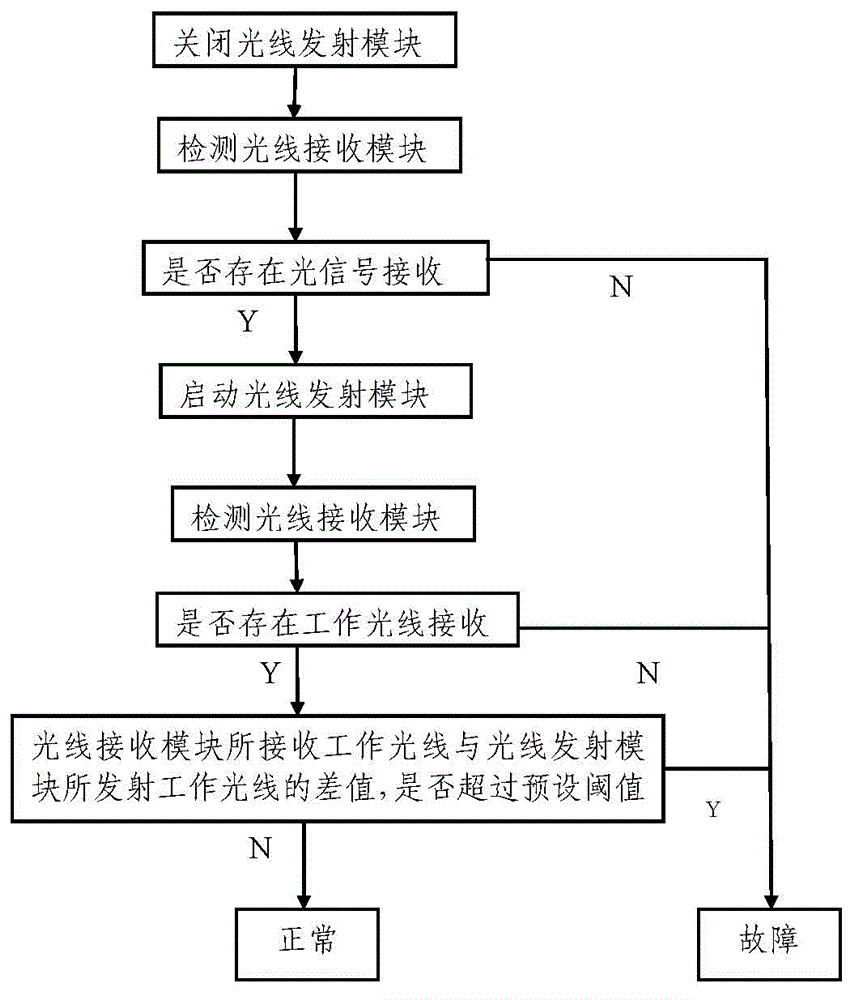

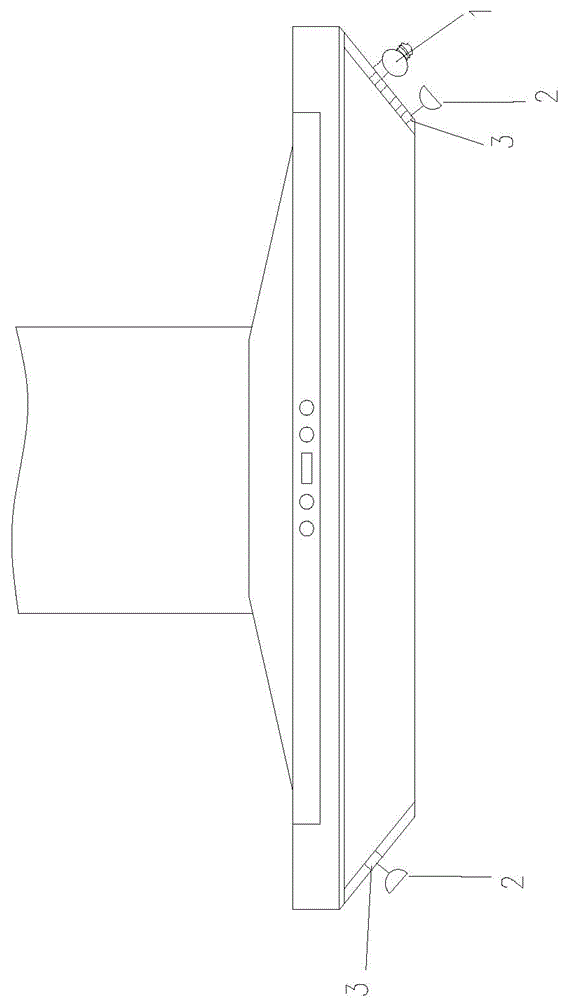

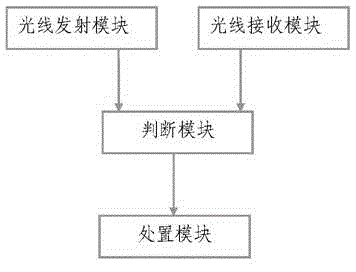

[0032] like figure 1 As mentioned above, in this embodiment, the self-inspection system for the range hood with automatic speed regulation includes a light emitting module, a light receiving module and a judging module, the light emitting module can emit working light toward the smoke collecting cavity of the range hood; The light receiving module can receive the working light emitted by the light emitter and passed through the soot area and reflected by the soot area; the judging module obtains the signal value of the working light emitted by the light emitting module and the light receiving module Receive the signal value of the working light, and judge the equipment failure based on the obtained signal value.

[0033] The fault judgment result of the judging module includes: (1) When the light emitting module does not emit working light, if the signal value of the light received by the light receiving module is zero, it is judged that the light receiving module is faulty. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com